As the summer heat descends upon us, I am reminded of travel stories some of my colleagues have mentioned about their recent summer trips abroad.

Whether from somewhere in Europe or down in South America, hearing their restaurant stories from their travels always intrigues me. Factors such as a lack of tipping to the overall size of the operations they visit impact these restaurants’ operating parameters.

Restaurants may continue to evolve in a post-COVID-19 world but what constitutes their operating parameters remains the same: processes, procedures, facility, labor, equipment and technology, menu and promotions. Comparing and contrasting the majority of restaurants in the United States with those outside of the country presents us with the opportunity to beg, borrow, and import ideas from our neighbors across the globe on how to optimize foodservice operations across all industry segments.

Take, for example, server simplification and the evolution of the role front-of-house team members play.

In many countries, it is common for servers to use handheld point-of-sale devices when taking customer orders tableside. Additionally, when it comes time to close the guest’s check, the server will bring the handheld POS terminal to the table and complete the transaction in front of the guest. This approach can truly be a time-saver for both the guest and the server at the start of the check and the closing of the check.

In their travels, my colleagues have preferred this method of table service over the most commonly used method in the U.S., where the server writes down the order, walks to a fixed terminal, and proceeds to enter the order only to follow a similar process when closing the tab. It’s really ironic when you think about it. In the back of the house, our designs are all about minimizing the number of steps staff take to do their jobs. Yet that way of thinking has not fully made its way to the front of the house, where it would be very impactful, too.

In fact, when we have worked with concepts simplifying the server role through the addition of a handheld order-taking device, handheld payment, or a combination of both the data paints a positive picture both from a staff and customer perspective.

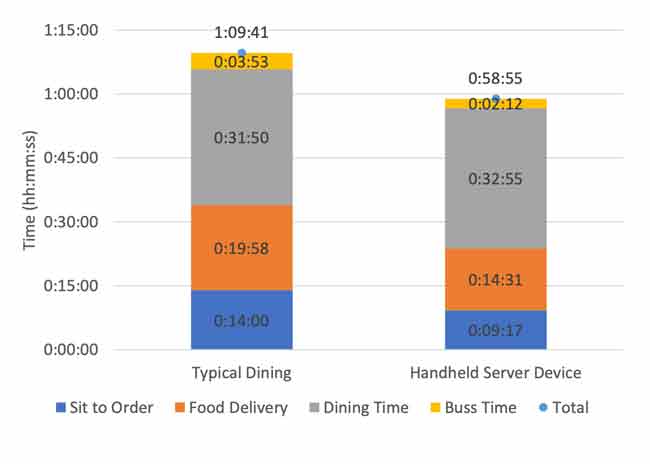

This graph summarizes the results from one concept testing the use of handheld devices for order taking and cashing out.

During this study, the concept was able to actualize a savings of 11 minutes per table, on average, when using a device to take the order and immediately send to the kitchen, as well as take the credit card payment at the table.

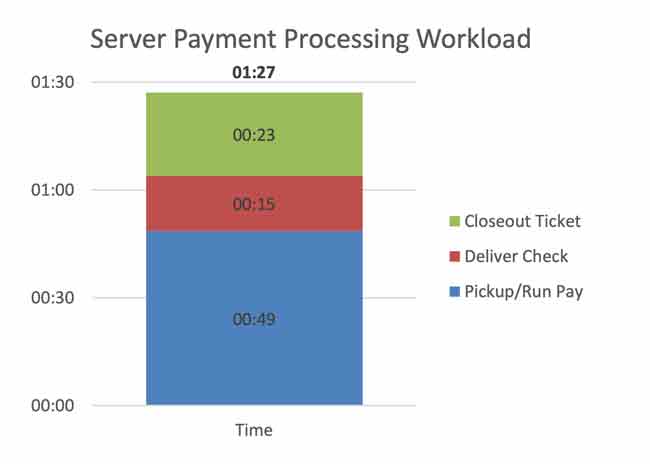

In addition to dining faster, the server experiences direct work-content savings of close to 90 seconds per table, which can be used to increase guest interaction in a variety of ways.

In another instance, an operator took things a step further by reallocating the ordering and cash-out responsibility from server to guest. The guest uses their cell phone to order, reorder, and cash out when ready. The real success story is how this concept revamped the server position from server to food and drink runner/guest ambassador. Rather than having a team of servers, this front-of-house has a team of food and drink runners and guest ambassadors. As a result of reallocating the work, all of the FOH staff now focuses more on the guest experience. The team is responsible for promptly greeting guests within seconds of their being sat and then focuses on guest satisfaction versus order entering and cashing out.

When working on our businesses, we are right to be laser-focused on the task at hand. That said, there’s often a benefit from picking up our heads from time to time to see how others approach their business, too. This is just one example of how we can import more than just commodities from our overseas partners.