Penn Medicine Lancaster General Hospital (LGH) in Pennsylvania, part of the Penn Medicine health system, radically transformed its foodservice.

Partnering with Morrison Healthcare, the change is part of a $182-million-plus overall hospital expansion and renovation. The project included bulk storage on the basement level, a main kitchen with a patient room service area, and Central Table Eatery, a food hall-style dining space.

Photos by VisionBuilders Design and Morrison Healthcare“The concept for the project was born from a vision to transform the existing cafe and dining hall into a vibrant community hub that reflects the identity of Lancaster and serves as a point of pride for LGH, showcasing its values and mission,” says Nick del Valle, system director of food services, Morrison Healthcare. “Since this is the number one health system in this geographical location, the new foodservice was designed to create an exceptional restaurant-style menu for patient room service and a unique retail food hall-style dining experience for staff and visitors. Central Table Eatery is a unique dining experience for a hospital setting.”

Photos by VisionBuilders Design and Morrison Healthcare“The concept for the project was born from a vision to transform the existing cafe and dining hall into a vibrant community hub that reflects the identity of Lancaster and serves as a point of pride for LGH, showcasing its values and mission,” says Nick del Valle, system director of food services, Morrison Healthcare. “Since this is the number one health system in this geographical location, the new foodservice was designed to create an exceptional restaurant-style menu for patient room service and a unique retail food hall-style dining experience for staff and visitors. Central Table Eatery is a unique dining experience for a hospital setting.”

Central Table Eatery, the retail part of the project, strives to provide a welcoming environment that fosters community interaction, engagement and connection. “This project aims to be more than just a functional dining facility,” says the project’s foodservice consultant, Keith Fennelly, partner, VisionBuilders Design, Charlotte, N.C. “It is envisioned as a cornerstone of the community that supports social interactions and a sense of belonging among staff and visitors. In addition, one goal was to take a community-centric approach and draw in local residents, making it a destination not just for medical services but also for social interactions and culinary experiences.”

“The Central Table Eatery offers a welcoming place of respite, one that reflects the importance we place on the well-being of our patients, our visitors and our employees,” adds John Herman, MBA, FACHE, CEO of Penn Medicine Lancaster General Health. “Through local vendors, our foodservice partners and our talented staff, the eatery is yet another way we are strengthening the health and well-being of our community.”

To achieve such lofty goals, though, the facility could not simply offer what many would perceive as the hospital foodservice. “We wanted to offer a dining experience that would stand up to business and industry operations such as Microsoft and Google. We’ve invested in culinary training to keep staff engaged and remain for longevity,” says Stephen Gotthelf, CEC, regional executive chef for Morrison Health and the hospital.

The project was structured as a multiphased renovation to ensure a smooth transition and minimize disruption to daily operations. “The phased approach for a progressive transformation of the facility allowed for the seamless construction and integration of various components within the facility while maintaining essential services,” Fennelly says.

The Transformation

The hospital was last renovated in 2002 and was designed to accommodate 85,000 annual patient visits. By 2018, the hospital was accommodating more than 100,000 patient visits in its Level I trauma and emergency departments.

Hearth & Co. features pizzas and Italian menu fare baked in two hearth ovens. Understanding the need to provide for the care of the community now and in the future, health system leadership pursued expansion and modernization of the foodservice department. After considering several approaches, the leaders and design team ultimately decided to completely relocate and expand the hospital’s existing kitchen and dining areas from the ground floor to the second floor. All product receiving and handling within bulk storage takes place on the lower level. This made way for a single-story 84,000-square-foot trauma and emergency department, which will accommodate 140,000 annual patient visits.

Hearth & Co. features pizzas and Italian menu fare baked in two hearth ovens. Understanding the need to provide for the care of the community now and in the future, health system leadership pursued expansion and modernization of the foodservice department. After considering several approaches, the leaders and design team ultimately decided to completely relocate and expand the hospital’s existing kitchen and dining areas from the ground floor to the second floor. All product receiving and handling within bulk storage takes place on the lower level. This made way for a single-story 84,000-square-foot trauma and emergency department, which will accommodate 140,000 annual patient visits.

Of course, moving the kitchen to the second floor meant the project team had to completely rebuild it during Phase 1 of the project, which ran from 2019 to 2021. “Prior to the pandemic, the existing cafe and dining hall had already established themselves as valuable resources within the community, providing a comfortable and accessible place for community members to come here to dine,” del Valle says. “However, we recognized an opportunity to reimagine this space as a larger, multifaceted destination that would not only meet the immediate needs of the local population but also enhance their overall experience.”

Craft Beverage & Bakery features coffee, tea, breads, pastries and smoothies. Rapid speed ovens heat baked goods.The first step, prior to demolition, involved the construction of a temporary servery. Built in 2019, this temporary setup enabled foodservice to continue operating during the demolition of the existing kitchen and dining areas. “The temporary servery was even nicer than some other permanent serveries I’ve seen,” del Valle says.

Craft Beverage & Bakery features coffee, tea, breads, pastries and smoothies. Rapid speed ovens heat baked goods.The first step, prior to demolition, involved the construction of a temporary servery. Built in 2019, this temporary setup enabled foodservice to continue operating during the demolition of the existing kitchen and dining areas. “The temporary servery was even nicer than some other permanent serveries I’ve seen,” del Valle says.

Phase 1 of the project included construction of the back-of-the-house kitchen and a portion of the new Central Table Eatery food hall. Within this phase, several micro restaurants were introduced, plus a 24/7 upscale convenience store.

Phase 2, which began in 2022 and was completed in 2023, added more specialized micro-restaurants.

“Overall, the design creates a cohesive production environment that promotes efficiency, reduces bottlenecks, and ultimately enhances the consumer experience by maintaining a steady and reliable flow of high-quality menu items,” Fennelly says. “The focus on efficient food flow ensures that all stages, from receiving to storage, preparation, production and service, operate seamlessly and support the needs of the operations team effectively.”

Storage and the Main Kitchen

Deliveries of food and supplies arrive at a loading dock on the basement level. Team members place menu ingredients into the bulk storage area, which was renovated and expanded to accommodate the increased volume of ingredients and supplies necessary to support the upgraded dining venue. Basement-level storage includes one large bulk walk-in cooler, one large bulk walk-in freezer and dry storage.

Local restaurants use Foodworks, which contains a full array of cooking equipment, to prepare and display their menus.Team members transport ingredients from storage to the newly constructed back-of-the-house kitchen on Level 1 using two new dedicated foodservice elevators. This kitchen is strategically positioned adjacent to essential support spaces, allowing for streamlined movement and coordination among staff members. Catering and dry storage reside directly beside the elevators for quick and efficient access. Team members walk a short distance to the chef’s walk-in cooler and freezer, allowing for a streamlined transfer of ingredients to the cold storage area as needed.

Local restaurants use Foodworks, which contains a full array of cooking equipment, to prepare and display their menus.Team members transport ingredients from storage to the newly constructed back-of-the-house kitchen on Level 1 using two new dedicated foodservice elevators. This kitchen is strategically positioned adjacent to essential support spaces, allowing for streamlined movement and coordination among staff members. Catering and dry storage reside directly beside the elevators for quick and efficient access. Team members walk a short distance to the chef’s walk-in cooler and freezer, allowing for a streamlined transfer of ingredients to the cold storage area as needed.

The food prep area sits strategically between cold storage and dry storage. “This central position allows for seamless movement into the cold prep and primary cooking areas, which forms the heart of the kitchen,” Fennelly says.

The cold prep area contains a 60-quart mixer, 20-quart mixers and two slicers. The adjacent bakery space contains two six-gallon kettles, a spiral dough mixer, a proofer and two rotating deck bakery ovens.

The hot bulk food production area is split into two corridors. One supports the front-of-the-house retail micro-restaurants and catering. It contains two full rack combi ovens, a pasta cooker, fryer battery and a six-burner range with conventional ovens beneath. Team members also use four 60-gallon steam jacketed kettles to make soups and sauces.

The other hot bulk food production area contains a 60-inch countertop griddle, a 40-gallon braising pan, two double-stacked combi ovens, two double steamer stacks, a four-burner range with a conventional oven, induction cooktops and two roll-in blast chillers.

Near the production areas, team members work in four pods to build patient trays. Team members receive menu orders from a call center where team members receive patients’ orders taken by hosts/hostesses on tablets. In the pods, culinary staff gather cold menu items from air-screen refrigerators and ambient cabinets and place the food on trays. The tray-builders receive hot menu items that team members prepare on the main production line and a production line including a microwave convection oven and dual steamers. Hot wells hold several menu items prepared on the cooklines. Team members place the hot food on plates heated by an induction charger. They place assembled trays in carts that team members deliver to patient floors. Hosts/hostesses deliver the trays to patients and return trays to the elevators where team members take them down to the kitchen.

In addition to patient meal service, team members prepare meals for Meals on Wheels in a dedicated area in the main kitchen. “We put together 50 meals with hot and cold food in packages,” Gotthelf says. “Couriers pick up the packages and deliver them to people in the area.”

In all facets of the operation, local and sustainable ingredient sourcing is a pillar of LGH and Morrison Healthcare’s core food philosophy. “Nearly 30% of our purchasing stays local to Lancaster and surrounding counties,” Gotthelf says. “These ingredients include malt and cheese for the artisan pizza, many of the vegetables, ancient grains and the locally roasted coffee we serve our patients. To me, it’s all about blurring the lines between guest- and patient-specific recipes and creating something that stands on its own, something that’s uniquely our food.” Chefs also design menus with an emphasis on plant-forward cuisine, as well as gluten-free options.

Harvest Grill’s vertical rotisseries support menu versatility and options.

Harvest Grill’s vertical rotisseries support menu versatility and options.

Dish and Pot Washing

A flight type dish machine adjacent to a custom-made three-station scraping table supports cleanup. When soiled patient carts are brought to the kitchen, they are broken down immediately and all patient wares are processed through the dish machine for thorough cleaning. The soiled carts pass through a mechanical cart washer, which cleans and sanitizes them before they return to the cart parking area and are ready for stocking with meals for delivery to patients. The cart washer contributes to water conservation and streamlines the cleaning process. This system is designed for the team to handle patient carts with increased speed and efficiency, reducing manual labor and ensuring consistent sanitation standards.

Good Grain Deli features made-to-order sandwiches.Team members place pots in a four-compartment power soak sink with a prerinse faucet and a garbage disposer. The pot-wash room contains a vented, heavy-duty pot and pan washer to handle large cookware. Clean pots and pans are stored centrally between the dish room and pot-wash room so team members can easily access them for food production.

Good Grain Deli features made-to-order sandwiches.Team members place pots in a four-compartment power soak sink with a prerinse faucet and a garbage disposer. The pot-wash room contains a vented, heavy-duty pot and pan washer to handle large cookware. Clean pots and pans are stored centrally between the dish room and pot-wash room so team members can easily access them for food production.

Also in the dish room, a food waste management system processes approximately 25 pounds of food waste per hour through aerobic digestion. This equates to handling waste from approximately 31 to 75 covers per hour. “This system has the potential to divert up to 109.5 tons of waste from the landfill annually,” del Valle says.

“By incorporating this system, the facility not only significantly reduces its environmental impact but also lowers the costs associated with waste disposal,” Fennelly says. “These measures collectively enhance the overall sustainability of the foodservice operation, helping to minimize waste and optimize resource usage, while simultaneously supporting labor efficiency by streamlining waste management processes.”

Also contributing to sustainability practices and optimizing water usage and energy consumption, variable speed water wash hoods allow the kitchen team to adjust exhaust rates based on demand.

Micro-Restaurants

One of the micro-restaurants in Central Table Eatery, Craft Beverage & Bakery, resides near the production kitchen and catering area. This restaurant features menu items baked in two roll-in rack ovens. “The ovens allow the team to bake all the bread and pastries for the foodservice operations,” Gotthelf says.

This area also contains two barista stations with chromed espresso taps. “The equipment transforms the customer experience and allows more sightlines to the baristas making their morning coffee,” Fennelly says. From this beverage and bake shop, customers also order smoothies made in blenders.

Hospital staff and visitors have access to this station and can watch the culinary action from a corridor that separates the back-of-the-house and front-of-the-house. “We call this Highway 101, because it’s a main artery through the space,” del Valle says.

Designing the corridor presented challenges for the project team. “We had to accommodate a major public and staff thoroughfare within the front-of-the-house design,” Fennelly says. “This corridor, which connects the main hospital lobby to a key bank of public elevators, had to be integrated into the layout seamlessly.”

The solution involved positioning the back-of-the-house kitchen and bake shop along one side of the corridor, with full visibility to enhance the open, engaging atmosphere. On the opposite side, the scattered food hall layout was designed to complement this traffic flow, allowing for easy access and movement through the space while maintaining an organized and efficient operation.

The low ceiling heights within the existing hospital structure created another design challenge. To address this, designers placed large-format acoustical ceiling tiles and light-colored flooring throughout public areas, helping to brighten the ceiling and create an illusion of height. “This strategic use of materials reflects natural light, making the space appear taller and more spacious than it is,” Fennelly says.

The design of the food hall’s micro-restaurant concepts allows them to be self-sufficient and operate independently throughout the day. “The layout also includes multiple access points to the main kitchen, enabling staff to efficiently retrieve additional supplies or ingredients as needed,” Fennelly says.

All the micro-restaurants use sustainable packaging for takeout. “We have eliminated Styrofoam and moved to a combination of bio-degradable sugarcane and environmentally friendly, recyclable kraft paper,” del Valle says.

Earth Bowl features The Carvery with proteins, sides, sauces and rolls.Project designers crafted each micro-restaurant to feature a distinct character. “Unlike traditional dining spaces, this design integrates varied materials, finishes and customized signage for each station, where guests can enjoy both choice and variety, all within a unified and engaging environment,” Fennelly says. Several types of seating also contribute to customers’ varied dining experiences. In addition, the food hall functions as a third communal meeting space where hospital staff and visitors can gather for social interaction and collaboration at off-peak times.

Earth Bowl features The Carvery with proteins, sides, sauces and rolls.Project designers crafted each micro-restaurant to feature a distinct character. “Unlike traditional dining spaces, this design integrates varied materials, finishes and customized signage for each station, where guests can enjoy both choice and variety, all within a unified and engaging environment,” Fennelly says. Several types of seating also contribute to customers’ varied dining experiences. In addition, the food hall functions as a third communal meeting space where hospital staff and visitors can gather for social interaction and collaboration at off-peak times.

The design also emphasizes the use of technology to enhance efficiency and guests’ experience. “The new food hall’s strategic placement of order/pay kiosks has significantly improved throughput speed and guest satisfaction,” Fennelly says. “This streamlined approach not only enhances the overall efficiency of the operation but also creates a more seamless and enjoyable experience for visitors.”

The integration of kiosks, strategically positioned throughout the food hall, has resulted in a notable increase in sales revenue, according to del Valle. “We are also using customer-facing order status boards, order management screens and bump bars at the stations to track tickets,” Gotthelf says.

Food shields with built-in LED lighting and heat reduce the number of aluminum posts and glass supports, which can obstruct customers’ view of the food.

Another food hall concept, Market, serves as an upscale convenience store with grab-and-go sundry items displayed in refrigerated, frozen and ambient cases, and also serves as a concierge area for the Central Table Eatery.

Hearth & Co.’s rotating pizza ovens provide a visual showpiece for customers ordering, flatbreads and Italian sides and entrees. Neapolitan pizzas cook in 90 seconds.

Create, an island setup, contains a salad bar, soup station and stations for grains and bowls, hot entrees such as cheesesteak and Creole catfish, and grab-and-go menu items. Create also offers a hot buffet breakfast. Hot/cold wells hold menu items.

At Harvest Grill two vertical rotisseries allow team members to cook multiple proteins including burgers and chicken at the same time. This micro-restaurant also contains fryers. A pot washing area behind Harvest Grill includes a three-compartment pot sink with a spray faucet for efficient washing. Team members also use a vented heavy-duty pot and pan washer to support washing for the other micro restaurants.

Customers intrigued by culinary action come to Heritage to see a bright red cooking suite. It contains two open-burner ranges, a pasta cooker, a charbroiler, a plancha, a salamander and convection oven bases to support the team’s production of plated entrees. “The concept gives our culinary team a unique creative outlet that is certainly one of a kind for a hospital space,” Gotthelf says.

Another island showcases three concepts: Earth Bowl, which offers salads and other create-a-bowl choices, Umami, featuring sushi, dumplings, ramen and Asian bowls, and Good Grain Deli for sandwiches and subs.

Foodworks, a rotating partnership with local restaurants, contains its own cooking equipment. Employees from those restaurants use a four-burner range and a ventless griddle with a 48-inch cooking surface with a built-in fire suppression system. Umami staff also use this space as necessary.

The cooking suite at Heritage gives the culinary team flexibility to prepare a wide variety of menu items and intrigues customers as they watch the culinary action.

The cooking suite at Heritage gives the culinary team flexibility to prepare a wide variety of menu items and intrigues customers as they watch the culinary action.

The Project’s Success

This project is unquestionably successful. “The new patient kitchen space has resulted in superior accuracy and efficiency, optimized speed and allowed almost limitless menu reimagining,” Gotthelf says. “These key factors have all driven patient satisfaction to new heights.”

Since its opening, Central Table Eatery has demonstrated strong sales growth and record-high revenue. “Central Table Eatery is now part of the main thoroughfare of the hospital, and you don’t feel like you’re in a hospital,” Gotthelf says. “Compared with pre-COVID numbers, retail sales have jumped by about 67% and check counts have grown by 32%.”

Success isn’t measured solely by numbers. “Beyond financial gains, the true success of the project lies in the positive impact it has made on the community by enhancing the dining experience for staff, visitor and the local population,” del Valle says. “The careful balance between financial considerations and delivering a high-quality, enjoyable environment underscores the project’s commitment to both fiscal responsibility and community engagement.”

Market offers upscale snacks and gifts.

Market offers upscale snacks and gifts.

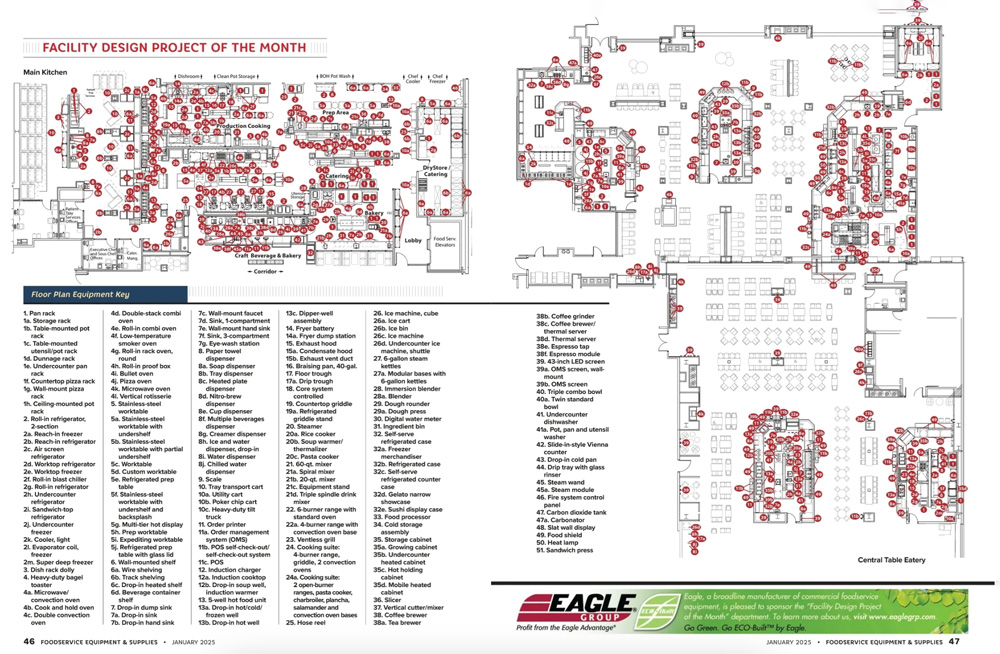

Floor Plan

Click here to download the floor plan and equipment key.

About the Project

- Opened: Main kitchen, February 2022;

-

Central Table Eatery, May 2022

-

Scope of project: renovation of main kitchen with room service and food hall-style dining space, all as part of a larger emergency department expansion project.

-

Website: morrisonhealthcare.com

- Lancaster General Hospital: 525 beds; affiliated with the University of Pennsylvania Health System

- Size: 39,313 sq. ft.; 1,272 sq. ft., outdoor patio

- Central Table Eatery Seats: 495 indoors; 80 outdoors

- Hours:

- Patient room service: breakfast, 6:50 a.m. until 9:30 a.m.; lunch, 10:50 a.m. until 12:30 p.m.; dinner from 3:50 p.m. to 6:30 p.m.

- Central Table Eatery, 7 days/week: 6 a.m. until 8:30 p.m.; third shift only, overnight, 2 a.m. until 4 a.m.

- Average check: $6.50

- Daily transactions/covers: Approximately 2,300 to 2,800; 80% of guests are hospital staff; 20% are visitors

- Total annual gross sales: $5.9 million

- Central Table Eatery with 9 micro-restaurants and 1 market:

- Craft Beverage & Bakery (espresso drinks/smoothies/pastries)

- Hearth & Co. (pizza, flatbreads and Italian sides and entrees)

- Create (salad bar, soup, grains, hot entrees and grab-and-go)

- Harvest Grill (burgers, fries, sides and milkshakes)

- Heritage (small footprint, plated concept, featuring local ingredients and

a Mid-Atlantic-inspired menu) - Earth Bowl (a combination of superfoods, grains and a variety of toppings for nutrient-dense power bowls)

- Umami (sushi, dim sum, ramen and Asian bowls)

- Good Grain Deli (freshly made sandwiches)

- Foodworks (features local restaurants)

- Market (upscale convenience store)

- Catering menu: Heart + Table; full-service menu

- Room service menu: Restaurant-style menu fare and rotating daily specials

- Staff: 14 Morrison Healthcare leaders and 140 LGH team members

- Total project cost: $32 million for full dietary renovation

- Equipment investment: Approximately $4.5 million

Key Players

- Owner: Penn Medicine Lancaster General Health

- CEO: John Herman, MBA, FACHE

- Foodservice operations team: Morrison Healthcare, a subsidiary of Compass Group USA

- System director of dining services: Nick del Valle, CDM, CFPP

- Regional executive chef: Stephen Gotthelf, CEC

- Associate director, retail: David Testerman, CDM, CFPP; Rachel Schaffer, MBA, RD, opening team

- Patient service director: Renee Harris; John Struble, opening team

- Architects: Perkins&Will Architects, Dallas, and Washington, D.C.: Ian Sinnett, AIA, ACHA, regional health practice leader

- Interior design: VisionBuilders Design, Charlotte, N.C.: Keith Fennelly, partner

- Engineers: WSP USA, York, Pa.: Matthew S. Peffley, P.E., HFDP, LEED AP, senior vice president

- General contractor: Benchmark Construction Company Inc., Brownstown, Pa.

- Foodservice consultants:

- VisionBuilders Design, Charlotte, N.C.: Keith Fennelly, partner

- Foodservice equipment contractors:

- Phase 1: Clark Foodservice Equipment, Lancaster, Pa.: Jeff Dahl, CFSP, sales executive

- Phase 2: Penn Jersey, Philadelphia: Steve McCarron, manager of contract sales