The design of Banyan Dining Hall at Brigham Young University–Hawaii in Laie, Hawaii, combines the history of the campus, Hawaiian culture and modern design.

Photos by Monique Saenz, university photographer, University CommunicationsThis was no small task, since BYU–Hawaii represents 70 different countries and cultures from the Pacific Rim, the U.S. mainland and other parts of the world. It is part of the Church Educational System of The Church of Jesus Christ of Latter-day Saints.

Photos by Monique Saenz, university photographer, University CommunicationsThis was no small task, since BYU–Hawaii represents 70 different countries and cultures from the Pacific Rim, the U.S. mainland and other parts of the world. It is part of the Church Educational System of The Church of Jesus Christ of Latter-day Saints.

“The whole dining experience tells a story of the many cultures here at BYU–Hawaii and the importance of breaking bread together,” says Dean Wright, recently retired managing director of BYU Dining Services in Provo, Utah.

“The dining facility is not about fusion,” says David Keala, director of Food Services, BYU–Hawaii. “It brings people together and encourages them to learn others’ cultures but not to lose your identity of where you came from.”

The name of the dining hall refers to the banyan tree that was located outside the old cafeteria, which served as a gathering space. “The old banyan tree that was removed for the project placement was important to the university and its students,” says Shawn Thomas, project director, Jacobsen Construction, Salt Lake City. “We were able to save the meaning of the banyan tree by building tables from the old banyan wood.” The new salad bar sits where the banyan tree was located.

“A banyan is a fig that develops accessory trunks from adjacent prop roots, allowing the tree to spread outward indefinitely,” Wright says, “On Maui, the banyan tree takes up a whole city block. We are like a banyan tree here. We have people from throughout the world, and they strengthen each other by putting roots down from wherever they come from.”

This dining hall replaces one built in 1960, which was demolished and became a plaza. As part of the process, the project team was challenged to build a facility that would initially serve 3,500 students and had to provide catering services without adding buildings. “We were challenged to design a new project for an irregular, constrained site in the middle of a functioning campus,” says James R. Brown, AIA, director of Planning, Design & Construction, BYU–Hawaii.

Meeting the project budget also presented challenges for the team. “With construction occurring through the worldwide pandemic, procurement of materials became very difficult,” says Thomas. “Even though we worked through one of the toughest times in history, the project still came in under budget, which was established prior to the pandemic.”

This project is the result of eight years of research, planning, design, construction and more. As part of this thoughtful and thorough process, Keala and members of the planning teams visited several colleges across the U.S. and Canada to identify best practices to integrate into Banyan Dining Hall.

“The team of our staff, architects, engineers, construction people and food consultants tried to bring freshness, ambience and a welcoming feeling to make it home-away-from-home for the many cultures represented here,” says Keala. “We learned so much from the schools, including that natural light is a critical component.” Bringing in natural light, different-sized windows in the dining hall and large windows throughout the building work together to create an open ambience.

When guests enter from the main entrance, they observe traditional longhouse-style architecture found in many Pacific cultures. “Guests see, smell and feel the experience of dining in this building,” Keala says.

Curvilinear design elements evoke impressions of ocean waves.The salad bar near the main entrance calls attention to fresh ingredients, and the visual of staff preparing food at several stations adds to the experience.

Curvilinear design elements evoke impressions of ocean waves.The salad bar near the main entrance calls attention to fresh ingredients, and the visual of staff preparing food at several stations adds to the experience.

A quiet color palette positions the food as the star of the culinary show. Blue screens above seats on the main floor represent ocean waves. The curves of the middle dining area represent Maui’s fishhook from native Hawaiian mythology. “The wave brings food and people together,” Wright says.

The project team also wanted the main dining seating curved, “unlike what the team saw in many campus dining facilities that had straight L-shaped table seating,” Keala notes.

The project took its shape from master planning led by H. David Porter, FCSI, president and CEO of Porter Khouw Consulting Inc., Crofton, Md., using PKC’s propriety principle of social architecture.

“With Albin Khouw, we helped BYU–Hawaii and other schools to create safe spaces, strengthen social capital, foster new friendships, nourish student emotional well-being and increase student retention and academic success. As part of this, we suggested a new approach for dining so the staff can produce food to order and en masse, depending on meal projections. And they can throttle up and down depending on peak/nonpeak hours. We suggested continuous service so students can come and go when they want. And changed to unlimited access meal plans.”

A cooking suite enables staff to work efficiently as they prepare a wide variety of menu items.

A cooking suite enables staff to work efficiently as they prepare a wide variety of menu items.

Back-of-the-House Prep and Dishwashing

After menu ingredients arrive at a loading dock, staff deliver them to a walk-in refrigerator and a walk-in freezer. Another walk-in refrigerator holds prepared food. “There is a linear flow from the dock to coolers to prep to cook/bake areas to the consumer,” Brown says.

In the cold prep area, staff use an automatic meat slicer, a bulk food processor, a cutter-mixer food processor and a buffalo chopper to prepare menu ingredients for use in the back of the house and for menu execution in the front of the house.

Staff prepare hot menu items in a 40-gallon tilt skillet, a 12-gallon and 25-gallon tilt kettle and a 60-gallon stationary kettle. The hot food area also contains a 48-inch charbroiler, a 2-burner range and 2 fryers with filters. Steamers produce 11,700 pans of rice, including 93% white and jasmine rice and 7% brown rice over the course of a year. “We produce so much rice because rice is part of our culture,” Keala says. “If we were to stack each pan on top of each other, we could reach the height of 6 Statues of Liberty, each of which stands as high as a 22-story building.” Rice pots reside at front-of-the-house stations as well.

The dishwashing and pot-washing area contains a pulper, a serviceware soak sink, a prerinse assembly station, a tray accumulator/conveyor, a flight-type dishwasher, a power agitating pot sink and a pot washer with a booster heater. This area is designed so dirty dishes come from upstairs to downstairs on the Ferris wheel and merge with the dishes dropped off on the main level. One employee gathers the dishes together to be loaded onto the flight machine.

The carving station enables guests to watch as staff carve proteins.

The carving station enables guests to watch as staff carve proteins.

Front-of-the-House Stations

Students, faculty and staff place their orders and/or pick up menu items at stations. Students purchase meal plans, while other guests pay with cash or card. “Because this is an all-you-care-to eat facility, we don’t need online ordering,” Keala says.

“Takeout isn’t encouraged because the dining staff and the university want people from different cultures to come together as a community and interact,” Wright adds.

The cladding on the hood and suite color were custom designed to reflect the red school color, Thomas adds. The style of the hood matches the wave format of the serving line. “Coordination between design and construction made this centerpiece outstanding,” he says. “The flow of the cooking and serving lines makes the Banyan feel open, and even when it’s crowded, you feel like there are plenty of options to choose from and places to go due to the open floor plan. With all the food options, nobody goes home hungry.”

The red cooking suite is the centerpiece of the dining room. Designers combined the cooking suite, which represents one of the school colors, and curved hood to call attention to the wave motif.

“Plug-and-play equipment that features quick disconnect was installed so stations can accommodate new trends and new equipment that appears on the market,” Brown says.

At Lava, there is a stone hearth oven for staff to cook pizzas, flatbread and casseroles. “Customers see the oven’s fire and red heat lamps, and the food from the oven is hot and bubbling — and you see the cheese melt like a lava flow,” Wright says. Contributing to the ambience, a mural of the Kona Coast on Hawaii’s Big Island depicts the view from one of the local volcanos. Cooked pizzas sit on a counter under heat lamps. Staff warm sandwiches in panini ovens.

At Grill, staff prepare burgers, fries, pancakes, waffles, French toast and several Asian menu items on a flattop grill, charbroiler and in fryers.

Guests can help themselves to cold desserts from the refrigerated bakery case.Staff carve roast beef, ham, turkey, chicken and pork at Carving. Boa buns cooked in combi ovens in the back of the house accompany the carved proteins. “Several menu items are prepared in the back of the house and quickly grilled in the front,” says President Galea’i, executive chef.

Guests can help themselves to cold desserts from the refrigerated bakery case.Staff carve roast beef, ham, turkey, chicken and pork at Carving. Boa buns cooked in combi ovens in the back of the house accompany the carved proteins. “Several menu items are prepared in the back of the house and quickly grilled in the front,” says President Galea’i, executive chef.

Lava-inspired decorations and wave motifs also appear at Local and World.

Local offers breakfast menu items including scrambled eggs, link sausage, French toast and house-made pancakes, including those of the chocolate chip variety. For lunch and dinner, Local features meatloaf, Japanese chicken curry, Greek plate lamb gyros, pork katsu with yellow rice, lu pulu with sweet potato and bibimbap.

World cooks international dishes, such as Thai chicken curry. Staff use the cooking suite, which it shares with Local, to prepare the dishes. The cooking suite contains a 60-inch griddle, a 6-burner range, a flattop griddle, 2 fryers, a conventional oven and 2 rice cookers.

During peak traffic periods, guests select menu items that have been prepared at all stations. Every station is staffed, so students with special needs make requests to accommodate these needs. Staff receive very few requests for special meal ingredients because there is so much variety at the stations. During slower traffic periods, staff has more flexibility, so guests can select ingredients and staff cook to order.

Lava station’s stone hearth oven cooks pizzas, flatbread and casseroles.Bakery features 12-feet by 4-feet windows, so guests can see bakers producing everything from bread, chocolate flan, pastries, guava and other cakes, and samoan panikeke, rolls and cookies. Staff use 20-quart and 60-quart mixers to make doughs, a dough sheeter, a 6-burner range and a couple of 6-gallon kettles to make sauces for desserts.

Lava station’s stone hearth oven cooks pizzas, flatbread and casseroles.Bakery features 12-feet by 4-feet windows, so guests can see bakers producing everything from bread, chocolate flan, pastries, guava and other cakes, and samoan panikeke, rolls and cookies. Staff use 20-quart and 60-quart mixers to make doughs, a dough sheeter, a 6-burner range and a couple of 6-gallon kettles to make sauces for desserts.

For the front-of-the-house part of Bakery, dessert ingredients sit in cold and hot wells next to the service counter. Staff place cold desserts in a refrigerated case for guests to help themselves to the sweets; staff top warm desserts with sauces and hand them to guests.

The self-serve salad bar contains eight cold wells and a refrigerated plate and bowl dispenser. Three rapid-speed blenders mix smoothies. “The blenders are self-cleaning, which is a tremendous labor-saving benefit,” says Galea’i. Another adjacent area contains an ice cream machine, and yet another area holds a toaster for bagels, a waffle maker and cereal-dispensing containers.

On the second level, guests find more seating and beverage stations. This area overlooks the first floor’s striking architecture and the food stations.

Sustainable Practices and Guest Satisfaction

Staff grow produce, such as green onions, spices and herbs to use as menu ingredients. “Many spices and herbs, such as basil, are hard for us to get here in Hawaii, and we use a lot of basil for curries and sauces,” Galea’i says.

“This is the only school in the U.S. that grows its own vanilla beans,” Wright adds.

The science department takes Banyan’s fryer oil waste to make diesel oil. The dining staff work with members of the science department on sustainable efforts. “They also make handwashing soap, and we use it in the back of the house,” Keala says.

The dining staff give waste from uneaten menu items to a local farmer, a BYU–Hawaii graduate, who uses the waste to feed pigs, which he gives to BYU–Hawaii dining for special events. In addition, staff use organic food waste to help feed and cultivate vermicomposting worms that in turn create fertilizer for the BYU–Hawaii garden.

Since Banyan Dining Hall opened, student participation continues to grow. “We’ve also been attracting more community members, especially on weekends and for special events,” Keala says. Staff also keep busy with catering for private dining facility guests, as well as a 140-seat outdoor area, the lanai, which was part of the overall design but was recently completed as another phase of the project.

The Banyan Dining Hall roots are deepening and expanding as students, faculty, staff and visitors learn more about their own cultures and those of their colleagues and peers.

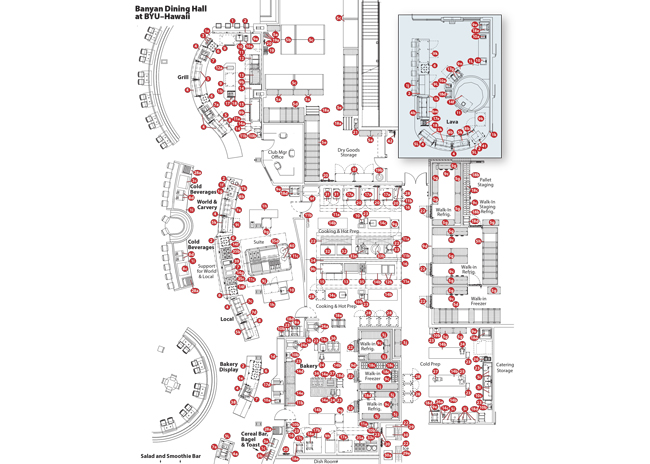

Floor Plan

Click here to download the floor plan equipment key.

About the Project

Size: 42,465 sq. ft.

First floor (main floor): 28,985 sq. ft.

Exterior lanai (side of facility): 3,500 sq. ft.

Dining room and serving area: 14,250 sq. ft.

Offices: 2,050 sq. ft.

Dish room: 960 sq. ft.

Kitchen storage, refrigeration, bakery etc.: 7,225 sq. ft.

Mechanical, electrical and generator room: 1,000 sq. ft.

Second floor: 13,480 sq. ft.

Exterior lanai (front of facility): 1,983 sq. ft.

Exterior lanai (side of facility): 663 sq. ft.

Exterior lanai (back side of facility): 6,634 sq. ft.

Large private dining room: 1,116 sq. ft.

Small private dining room: 190 sq. ft.

Seating (interior): 2,894 sq. ft.

Seats:

- First floor: 640 seats inside, 140 seats outside

- Second floor: 196 seats inside, 104 seats outside

- Private dining rooms: 72 seats in one and 8 in another

Hours:

- Monday through Friday

- Breakfast, 7 a.m. until 10 a.m.

- Late breakfast, 10 a.m. until 11 a.m.

- Lunch, 11 a.m. until 2 p.m.

- Dinner, 4 p.m. until 8 p.m.

- Saturday

- Brunch, 9 a.m. until 1 p.m.

- Dinner, 4 p.m. until 8 p.m.

- Sunday

- Lunch, 11 a.m. until 1:30 p.m.

- Dinner, 4 p.m. until 6:30 p.m.

Steam kettles and tilting kettles allow staff to prepare menu items in bulk.Menu concepts: Designed to fit the culture of Oceania and the Pacific Rim. Stations include Lava; Grill; Local and World, which share a cooking suite; Carvery; Bakery; Salad and Smoothie Bar; Soft-Serve and Cereal Bar; Beverages

Steam kettles and tilting kettles allow staff to prepare menu items in bulk.Menu concepts: Designed to fit the culture of Oceania and the Pacific Rim. Stations include Lava; Grill; Local and World, which share a cooking suite; Carvery; Bakery; Salad and Smoothie Bar; Soft-Serve and Cereal Bar; Beverages

Total staff: 207, including 19 full-time equivalents (40 hours/week); 177 students (19 hours/week); 11 part-time employees (30 hours/week)

Opened: April 20, 2022

Scope of project: Dining hall new build to include back-of-the-house kitchen and front-of-the-house stations and seating. A second story includes seating, a beverage station, a private dining room and a tray Ferris wheel to transport trays down to the first level.

Website: foodservices.byuh.edu/banyan-dining-hall

Key Players

- Brigham Young University–Hawaii

- University president: John S.K. Kauwe III

- Director of Food Services: David Keala

- Banyan Dining Hall manager: Marilou Lee

- Executive chef: President Galea’i

- Catering assistant: Chad William Tuttle

- Director of Design, Planning and Construction: James R. Brown, AIA

- Brigham Young University–Provo

- BYU managing director of Dining Services: Dean Wright (retired after project completed)

- Architect: CRSA, Salt Lake City; E. Benjamin Rogers, AIA, NCARB (currently at another firm)

- Interior and lighting design: CRSA, Salt Lake City

- Foodservice consultant: Porter Khouw Consulting Inc., Crofton, Md.: H. David Porter, FCSI, CEO, president; and Albin T. Khouw, senior vice president, emeritus

- Construction: Jacobsen Construction, Salt Lake City: Shawn Thomas, project director

- Equipment dealer: Restaurant & Store Equipment Co., Salt Lake City: LeGrande Steenblik, vice president