The remodeled Ventanas on the University of California San Diego campus is located in the Eleanor Roosevelt College building. It features five platforms — the team behind the project uses the word “nodes” — dedicated to cuisine inspired by the African Diaspora, as well as India.

Photos courtesy of UC San Diego, photos by Matthew Hansen and Shana Thang“Aside from a scheduled renovation of one of our residential dining restaurants, our primary objective was to raise awareness in the campus community of the African Diaspora and how it has influenced cuisines in the Western Hemisphere through the celebration of diversity and inclusivity,” says Jeffrey Palmer, senior director of Campus Dining with UC San Diego Housing, Dining and Hospitality (HDH).

Photos courtesy of UC San Diego, photos by Matthew Hansen and Shana Thang“Aside from a scheduled renovation of one of our residential dining restaurants, our primary objective was to raise awareness in the campus community of the African Diaspora and how it has influenced cuisines in the Western Hemisphere through the celebration of diversity and inclusivity,” says Jeffrey Palmer, senior director of Campus Dining with UC San Diego Housing, Dining and Hospitality (HDH).

The African Diaspora, which refers to the voluntary and involuntary movement of Africans, led to significant culinary contribution globally. African ingredients and cooking techniques fused with local traditions, shaping dishes such as gumbo and soul food in the Americas. This fusion reflects the resilience, creativity and cultural heritage of African-descended communities, enriching culinary traditions worldwide.

“Ventanas showcases and serves underrepresented cultures in our dining program,” Palmer adds. “We have continually strived to create a welcoming and authentic culinary experience that reflects the richness of various cultures and fosters a sense of community and understanding among our campus community.” Contributing to the project’s success, Palmer says, was “collaboration with an architect who understood our campus’ dining needs and carried forward an aesthetic vision.”

The project also features a full-service coffee house, upgraded indoor and outdoor seating areas, and a new connection to a neighboring building on the UC San Diego campus. “The main highlights of the space are the sense of vibrancy and community the design fosters,” says Kristin Shultz, AIA, LEED AP, associate, HGW Architecture, San Diego. “We were also intentional with the materials selected and how they relate to UC San Diego’s vision of highlighting the cuisines of the African Diaspora. The design concept leaned into biophilic design by incorporating natural materials, live plants and organic shapes.”

The colors, patterns and textures of the wall tiles, which are primarily ceramic with some large format porcelain tiles, reinforce the connection to the menu ingredients. Living, leafy green plants weave through the space to connect the foodservice area to the dining room. “Another key element to the design is the fabricated, woven wood basket soffits highlighting the foodservice nodes,” Shultz says. “These assist with wayfinding, reinforce the biophilic design elements and relate back to the use of baskets in the transport and display of food items throughout history.”

Decorative pendants made from natural materials such as wood, aluminum, ceramic and concrete hang over the seating areas and at the nodes. In addition, the design team selected quartz solid surface counters in the foodservice and dining areas, as well as nonporous solid surface community tables and casework tops for their aesthetics, durability and cleanability. Thirty-foot-high floor-to-ceiling windows allow in natural light, while LED lighting also brightens the inside spaces.

The renovation of the residential dining offering, which the university refers to as a restaurant, was set on an 18-week fast track for construction. “Ensuring that the finishes were readily available and nearby was very challenging,” Palmer says. “The design team had to be flexible when respecifying items when lead times were prohibitive. Yet the team has a great relationship with product representatives and were able to work with them to find alternatives that met the design intent and were not a compromise to the project.”

Guests move through the space with ease.

Guests move through the space with ease.

Project Flow

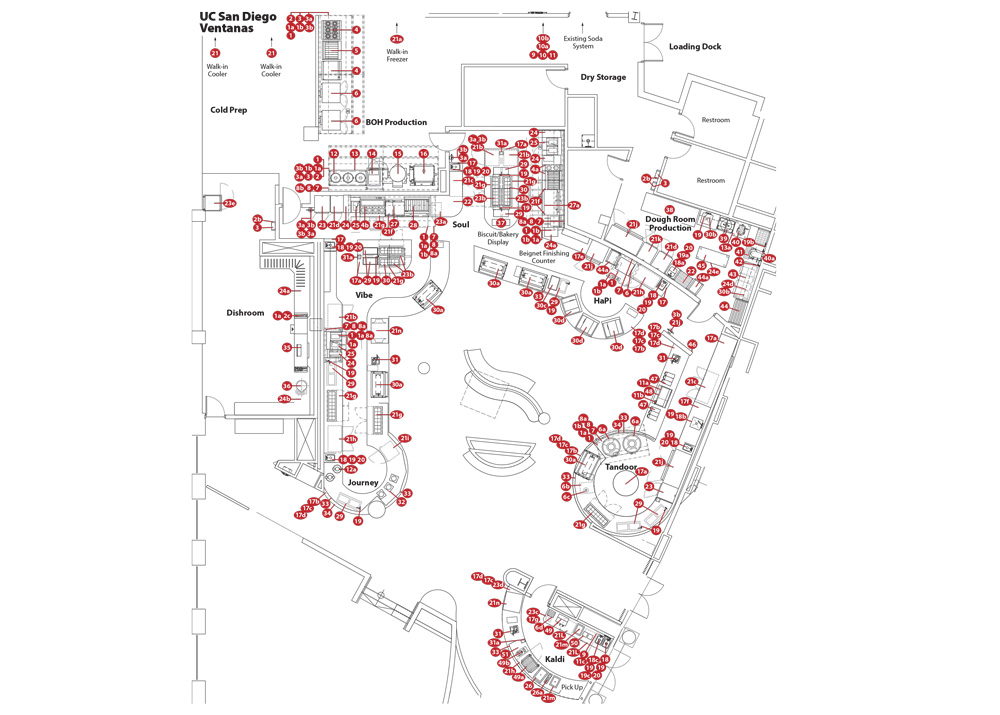

Existing building layout and infrastructure affected placement of functional areas. The project’s focus involved renovating the front-of-the-house servery. The back-of-the-house kitchen layout remained mostly unchanged, though multiple equipment upgrades were made in this area. Offices were removed, and prep was expanded near the receiving area to support two nodes. The dishwashing area remained in its original space, maximizing the existing infrastructure as much as possible.

The design flow establishes a streamlined pathway for the completion of menu items. In the front of the house, the servery was rearranged to create more menu options and efficient back-of-the-house access. With the previous layout, staff would have to walk past two other stations to access the kitchen, disrupting the cookline, especially during high-peak meal periods. With the current design, each station has an individual line of access to the central back-of-the-house kitchen, allowing existing staff not to be disrupted.

“The most impactful improvement for circulation and flow was the design of a new opening from back of the house to front of the house to relieve crossover traffic and allowing direct support for each venue,” says Ken Relethford, president, CEO and owner, Orness Design Group, San Diego. “The challenges we identified were working within the confines of the existing servery, creating an entirely new service style compared to the previous style of service.”

Prior to the renovation, Ventanas’ features were typical of a 20-plus-year-old cafeteria: linear service counters, a mix of self-service, grab and go, and limited cook-to-order menu items, and customers exiting through a staffed point-of-sale. “The elimination of self-serve food venues and the creation of more made-to-order venues and elimination of the point-of-sale exiting point transformed the space into a modern high-quality foodservice venue for the campus,” Relethford says.

The new approach to the service style allows customers to experience different African or African-influenced cuisines, mimicking the experience of shopping at food stalls. “The integration of our dining mobile ordering app has led to a higher ratio of advance ordering compared to in-person line queuing, eliminating traditional cafeteria-line service, thus reducing in-person queuing needs,” says Ralph F. Dauphin, associate director of Dining Services Planning and Development.

“COVID-19 has had its impacts globally and forced us to be creative with service methodologies to serve our students safely,” Dauphin says. “Reducing the density in our locations and adhering to the six-foot distancing was difficult in traditional line queuing. It forced us to think, ‘How can we serve our residents without having them physically in line to order food?’”

This kicked off the mobile app, which students and UC San Diego-affiliated staff can use to order food with their dining plans or other digital payments at any UC San Diego residential dining or market location. The app has real-time queuing calculations, allowing guests to see how long their meal will take to prepare and notifying them when the order is complete.

“Students and staff no longer have to wait in line to order their food, but rather they can place their order while they are in lectures or their rooms and head over when it’s ready for pickup,” Dauphin says. “Why wait in line when you can remain productive until your food is ready?”

With the launch of the app during the pandemic, the restaurants were able to regulate and control the density within the building, allowing guests to eat at safe distances if they chose to stay on premises. Many consumed their food in their rooms.

“Although COVID-19 regulations have decreased, the app has remained in use and has become the dominant form of food ordering, with 87% of orders going through the app,” Dauphin says. This app is used predominantly by students with a dining plan, but there has been an increase in use by UC San Diego-affiliated staff and faculty as more return to campus to work.

Every restaurant has a designated warmer/cooler at the stations where completed meals are kept warm/cold before guest pickup. Guests who do not have the app can still order in person at one of the restaurant’s point-of-sale stations.

Thirty-foot-high floor-to-ceiling windows and lighting elements create a unique ambience and invite guests to relax while they dine.

Thirty-foot-high floor-to-ceiling windows and lighting elements create a unique ambience and invite guests to relax while they dine.

Deliveries and Production

Staff receive deliveries from the back loading dock. They break down pallets on the dock and move them to dry storage. They inspect menu ingredients, check temperatures on the frozen and perishable menu ingredients, reject damaged menu ingredients and document all shortages. Staff also date menu items as received. Prioritizing perishables and frozen menu ingredients, staff store raw goods such as legumes and grains, fresh produce and juices in a walk-in cooler and other produce in another walk-in cooler also used for storing sauces, marinades and prepared proteins.

Staff place bulk proteins, breads, desserts and frozen produce in a walk-in freezer and place other ingredients in dry storage. Menu items for the allergen program have their own designated storage within each area. Staff prepare all allergen meals on a separate prep table furnished with purple-coated cookware and a separate inventory of dry ingredients.

Cold production takes place on both sides of the back-of-the-house kitchen. One side contains stainless-steel tables adjacent to the dish room. Staff working in the cold prep areas prepare mise en place using a food processor, a stationary blender, an immersion blender, electronic scales and a meat tenderizer. The dough room contains a 40-quart floor mixer, a 20-quart tabletop mixer, a dough-portioning machine, two dough sheeters and four pastry turnover machines.

Additional cold prep takes place on the hot production side, which holds two convection ovens for roasting proteins and vegetables, a flattop griddle for sauteing breakfast menu items and vegetables and a charbroiler for searing proteins. Staff also prepare rice in large rice cookers, steam or parcook vegetables in steamers, prepare lentils and sauces in the large tilt kettle and cook large batches of gumbo and chana masala in the tilt skillet.

“Taking full advantage of the state-of-the-art equipment is of utmost importance in allowing the team to focus on safely cooking, cooling and storing food,” Dauphin says.

Staff prepare most menu items in bulk in the central kitchen. After preparation, they place food in smaller stainless-steel containers that are held on the station for service or in the hot holding cabinets for safe holding. Menu items that need to be cooled are cooled in accordance with HACCP specifications, typically in the blast chiller.

Also in the back of the house, a large dish room contains a conveyor dish machine, a triple sink for warewashing and a disposal that sits in a scraping area. Bussers and prep team members deliver dirty dishes and smallwares to the dish room. They drop off larger pots and pans at the warewashing station and stage dishes, baskets and serviceware at the dish machine where a dishwasher guides them into the machine.

After items are sanitized, dishes air-dry before staff place these items onto the shelving racks. Staff wash the bigger pans in a three-compartment sink. They soak-scrub pots of debris before washing and sanitizing them. Next, they throw all buckets full of compost into the larger compost container outside.

Kaldi contains coffee grinders, coffee and tea brewers, blenders for smoothies and display cases for pastries and grab-and-go bites. Photo by Shana Thang/ UC San Diego

Kaldi contains coffee grinders, coffee and tea brewers, blenders for smoothies and display cases for pastries and grab-and-go bites. Photo by Shana Thang/ UC San Diego

Front-of-the-House Nodes

Relethford explains that the team determined the nodes’ locations based on expected customer volume and the equipment required for the desired menu. Journey, one of the largest stations, sits close to the dining area and entrance. Vibe and Soul feature many cook-to-order menu items.

Two copper tandoori ovens support menu item production for Tandoor.“Designing the hood systems to tie into existing mechanical chases required these stations be located near the back-of-the-house kitchen,” Relethford says. In Tandoor, the bright copper-finished tandoor ovens also sit near the front dining area. HaPi and beverage stations, with the smallest special requirements, are located in transitional areas.

Two copper tandoori ovens support menu item production for Tandoor.“Designing the hood systems to tie into existing mechanical chases required these stations be located near the back-of-the-house kitchen,” Relethford says. In Tandoor, the bright copper-finished tandoor ovens also sit near the front dining area. HaPi and beverage stations, with the smallest special requirements, are located in transitional areas.

“The placement of the coffee bar during schematic moved several times,” Relethford says. “Providing 3D models and sharing the options with the decision makers determined the final placement.”

Each node features a distinctive style of cuisine and was designed for the most expeditious execution possible. After receiving orders via the dining mobile ordering app, staff finish or assemble most menu items at each node and place them on a nine-inch plate or in a basket. Next they place menu items in heated see-through glass containers, which stay warm until guests arrive. When guests arrive, staff ask them for an order number and present them with their order. “Food is left out no longer than 30 minutes to ensure freshness and quality standards to guests,” Dauphin says.

Each node’s equipment is tailored to its menu. Most stations feature standard equipment such as refrigerators, hot holding wells, griddle tops, charbroilers, fryers and drop-in cold and hot wells.

Journey features African cuisine. “African cuisine is a diverse and rich tapestry of flavors and culinary traditions that vary widely globally,” says Dauphin. “Food in Africa is culturally significant, often tied to rituals and celebrations, and street food is a lively part of the culinary landscape.”

Staple foods include grains such as maize, millet and rice, and root vegetables such as yams and cassava. Protein sources range from meat to poultry and fish to legumes. Spices and seasonings add bold flavors, with different regions using various ingredients such as cumin, paprika and ginger. Traditional sauces, condiments and cooking techniques further define the cuisine. Dishes at Journey embrace the spices and traditional seasonings of Africa and include chicken doro wat, bhajias kan kan, yadoro, akara fritter and plantain, piri piri shrimp and beef kofta. Desserts include ingredients like honey, fruits and nuts.

Staff in the back of the house cook rice, soups, vegetables and proteins. In the front of the house, staff at Journey hold menu items warm in a rice holder, hot wells and induction warmers.

Vibe features Caribbean cuisine and includes African, European and Asian influences into a harmonious medley of bold, savory flavors. Scotch bonnet peppers, allspice, thyme and scallions infuse dishes with a distinctive Caribbean zest, paying homage to the rich ancestral heritage of Black communities across the islands. Dishes on Vibe’s menu include rasta pasta, jerk chicken, sofrito, tostones and guisado plates.

Vibe contains a six-burner range, a 36-inch flattop griddle, a 48-inch charbroiler and a fryer. Refrigeration sits beneath the hot equipment. Heated reach-in cabinets and heated drop-in wells keep menu items warm. Cold wells sit on the other side, holding garnishes and toppings for bowls. “We had to get creative with our equipment lineup,” Dauphin says. “We asked ourselves, how can we push food out faster with more residents to feed? We worked with the architects to incorporate an island setup.”

The island setup is a mirrored prep table with hot wells on one end and cold wells in the center. The ingredients are mirrored on both sides of the prep island, so multiple staff can dish up orders at the same time as they go down the line.

“We’re trying to streamline our platforms so we can offer food to an increasing number of students,” Dauphin says. “We now have about 14,400 undergraduate residents, and we’re moving toward having 20,000 in the not-too-distant future.”

American Southern cuisine features at Soul. This region’s food is a celebration of rich flavors and heritage, born from the historical influence of African, European and Native American cultures. Menu ingredients include okra, black-eyed peas and rice, most of which are slow-cooked. The African influence on Southern cuisine is evident in Soul’s dishes such as gumbo, jambalaya, and collard greens.

Staff at Soul prepare breakfast and lunch menu items using fryers, charbroilers and a griddle to serve waffles, biscuit sandwiches and eggs with muffins, and burritos. The menu will soon also feature beignets. Staff place menu items in hot holding cabinets.

Tandoor offers Indian cuisine, renowned for its diverse and bold flavors. Two tandoori ovens support staff as they cook kabobs with vegetables, palak paneer, chana masala, tikka kathi, biryani, korma and house-made naan. The ovens, which can be heated to 550 degrees F, give naan, a soft and leavened flatbread, its distinctive charred and slightly crispy texture and infuse it with a delightful smoky aroma. “Naan must be made to order, and guests can watch this,” Dauphin says.

“We were limited in the space available to place exhaust hoods,” Dauphin says. “We had to cover the tandoori ovens. We didn’t have the hood space to cook large quantities of curries, which are best prepared in medium or large batches, so most curries and stew-like dishes are made in the back of the house and brought to this area and held in hot wells.”

HaPi derives its name from the first two letters of “hand” and “pies,” a globally cherished menu item. The offerings at this node feature a diverse array of fillings that encapsulate the essence of international culinary traditions.

Staff make dough for the hand pies in the dough room and fillings in the back of the house. Jamaican beef patties feature a flaky pastry filled with spiced ground beef, representing the Caribbean’s rich cultural influences. Latin American empanadas contain fillings that highlight various regions’ culinary diversity. HaPi also offers sweet hand pies with caramelized and fruity fillings, like plantain and apple empanadas. Staff warm pies in a high-speed electric oven.

Finished pies are displayed in cases topped with hot or cold sauces before staff hand them to customers.

Kaldi contains coffee grinders, coffee and tea brewers, blenders for smoothies and display cases for pastries and grab-and-go bites. The name of this platform connects to a folktale of coffee’s discovery being intertwined with a goat herder named Kaldi who noticed his goats became unusually lively and energetic after munching on the bright red berries of a particular shrub, which sparked the birth of coffee culture.

Soul contains fryers, a range with a cold rail above, a griddle, charbroiler and hot holding cabinets.

Soul contains fryers, a range with a cold rail above, a griddle, charbroiler and hot holding cabinets.

Sustainability Practices

All renovation projects at UC San Diego must adhere to the Silver LEED standard mandated by the university, ensuring energy efficiency in all renovations and new developments, including equipment. The dining facility exceeds these requirements by offering post-consumer composting for guest use. Staff promote sustainability by encouraging reusable items and limiting single-use products.

Guests can participate in the university’s sustainability initiative by purchasing a $5 reusable takeout container, paying a deposit upfront, taking their meals to go, and returning the container to a designated machine to receive a $5 credit back to their dining plan. The bright green reusable containers feature a translucent top and are shaped like both a rectangular box and a bowl. Customers later drop these containers into an eco box, which is located in every dining hall, and collected by team members before washing.

“Through initiatives like composting and reusable containers, we have established a closed-loop cycle that aligns with our campus goal of achieving zero waste,” Dauphin says.

In addition to introducing a new menu, the team members meticulously work to ensure the ingredients and recipe quantities are accurate to maintain predictable food costs and determine pricing. “This attention to detail in recipe writing allows us to forecast our expenses more effectively,” Dauphin says. “Efficient management of our storage and coolers helps us minimize food waste.”

One way the Ventanas team looks to limit food waste is to offer a diverse menu that cross-utilizes ingredients. “Having specialized staff for tasks like dough preparation ensures a consistent quality of products like naan, empanadas, and beignets,” Dauphin says. “This approach helps us avoid inconsistencies that could lead to food waste.”

As part of a commitment to energy efficiency, the HDH team uses an all-electric oven for the empanada station and a steam-powered griddle top for even heating, thereby reducing reliance on gas.

“HGW’s architects’ and interior designers’ talents to bring in design features and finishes to the space is what really sets this facility apart from others,” Relethford says. “The UC San Diego HDH team’s vision for the space and their project management support led us. There were numerous challenges on this project such as working within a fixed budget, existing space restrictions, and a very short time frame to turn around design drawings and construction completion. All are elements that only a hard-working, finely tuned team with ownership support can complete on this level.”

Ventanas’ emphasis on the African Diaspora and the movement of food and spices to the Western Hemisphere, along with its design, decor and overall aesthetics, creates a unique and culturally rich dining experience. The innovative concept focuses on a sense of connection and appreciation for diverse cultural histories. “This uniqueness sets Ventanas apart from traditional foodservice facilities, making it stand out among all our other designs and dining concepts,” Palmer says.

Floor Plan

Click here for the floor plan equipment key.

About the Project

- Opened: September 2023

- Scope of project: The remodeled Ventanas residential dining restaurant features a year-round menu and multiple food platforms dedicated to cuisine inspired by the African Diaspora. Ventanas is one of two renovation projects completed in the 2023-24 academic year.

- Website: hdhdining.ucsd.edu

- Size: Total square footage: 10,645

- Front-of-the-house platforms and Kaldi: 6,198 sq. ft.

- Back of the house: 4,447 sq. ft.

- Seats: 290 (182 indoors, 108 outdoors)

- Average check: $8.35

- Total annual sales: $1.3 million (as of March 2024)

- Daily transactions/covers: 1,309

- Hours:

- 7 a.m. to 11 p.m., Monday through Thursday

- 7 a.m. to 8 p.m., Friday

- 10 a.m. to 8 p.m., Saturday and Sunday

- Menu concepts and specialties:

- Journey — West, Central and East African cuisine

- Vibe — Caribbean cuisine

- Soul — American soul and Southern cuisine

- Tandoor — Indian and Southeast Asian cuisine

- HaPi — hand pies

- Kaldi — espresso, coffee, brewed teas and other drinks

- Total staff: 40 full-time and 75 student employees

- Total investment: $10 million

- Equipment investment: $2.5 million

Key Players

- Owner: University of California San Diego

- UC San Diego Housing, Dining and Hospitality:

- Senior director of Campus Dining: Jeffrey H. Palmer

- Associate director of Dining, Operations: Leo Acosta

- Associate director of Dining Services Planning and Development: Ralph F. Dauphin

- Senior executive chef: Vaughn Vargus, CEC, CCA

- Project planning analyst: Shana Thang

- Architect: HGW Architecture, San Diego.: Sean Chen, AIA, principal; Kristin Shultz, AIA, LEED AP, associate

- Interior design: HGW Architecture, San Diego: Magdalena Kubik, NCIDQ IIDA

- Foodservice consultant: Orness Design Group, San Diego: George Orness, retired; Ken Relethford, president, CEO, owner

- Equipment dealer: Economy Restaurant Equipment and Supply Co., San Marcos, Calif.: Nick Gentile, vice president, sales manager

- Construction: Suffolk Construction, San Diego: Andrew Dacri