The original cafeteria built in 1959 at the private Christian Brothers Academy (CBA) in Lincroft, N.J., needed revamping. The all-boys student population in grades 9 through 12 needed a place to not only find contemporary menu items but also enjoy them in a more modern and brighter environment conducive for mingling.

CBA was founded in 1955 and has undergone several expansions. Photo below by Paul S. Bartholomew“When the original cafeteria was built, the school was smaller in terms of the number of students,” says R. Ross Fales, president of CBA. “In order to accommodate the 825 students that we have now, we needed six lunch periods each day. This locked in our schedule in a way that would not allow much variation or additional programming.”

CBA was founded in 1955 and has undergone several expansions. Photo below by Paul S. Bartholomew“When the original cafeteria was built, the school was smaller in terms of the number of students,” says R. Ross Fales, president of CBA. “In order to accommodate the 825 students that we have now, we needed six lunch periods each day. This locked in our schedule in a way that would not allow much variation or additional programming.”

CBA’s renovation project added 40% more space through a combination of an 815-square-foot addition and by taking a portion of adjacent instruction rooms. The additional space allowed CBA to hold as few as three lunch periods. This allowed the school to change its daily schedule and add additional academic programming.

The modernization into a dining hall also allows more from-scratch food preparation with a goal of providing healthier and more diverse menu options. “We were originally looking for a food court-type layout to give more of a college feel, but even with the expansion, we did not have enough space for that, so this is a modified food court with different stations,” Fales says. “We also wanted to be able to get large numbers of students through in each lunch period, so we needed openness and multiple checkout lines.”

The foodservice renovation required designers to add seating capacity, as well as redesign the food serving and pay lines to match the increased number of students the facility would serve at each lunch period. “A single serving line with ample circulation allows students to go directly to a serving station for their desired meal,” says Eric L. Wagner, AIA, principal in charge, Kellenyi Johnson Wagner (KJW), Red Bank, N.J. “Menus are displayed on TV monitors suspended over each station.”

The foodservice program, managed and operated by SAGE Dining Services, is supported by retail sales, though financial assistance is offered to some students by CBA. (The school does not participate in the government-subsidized National School Lunch and Breakfast programs.)

The project is one facet of the larger initiative that started in the 1950s when the architects, KJW, converted existing barns into classrooms on this former horse farm. Subsequently, KJW did six major expansion projects, bringing the total educational campus to more than 200,000 square feet and upgrading facilities including the library and administration wing.

Photos courtesy of Christian Brothers Academy; photos by Larry LevantiThough the original cafeteria and kitchen plans and layout were basically unchanged from the original construction of the school in 1959, all finishes and equipment needed a full overhaul. “In addition, the existing perimeter walls did not allow for expansion of the facilities as needed,” Wagner says. “This required removal of load-bearing walls and installation of steel beams and columns offering a more open floor plan. Removal of a load-bearing wall was also required to allow the kitchen to grow, adding a cash register portal.”

Photos courtesy of Christian Brothers Academy; photos by Larry LevantiThough the original cafeteria and kitchen plans and layout were basically unchanged from the original construction of the school in 1959, all finishes and equipment needed a full overhaul. “In addition, the existing perimeter walls did not allow for expansion of the facilities as needed,” Wagner says. “This required removal of load-bearing walls and installation of steel beams and columns offering a more open floor plan. Removal of a load-bearing wall was also required to allow the kitchen to grow, adding a cash register portal.”

The dining hall now has an entrance facing the rear parking lot. This permits groups using the space for evening events to enter directly from the outside, rather than having to go through the school building. A folding partition creates a furniture storage space for tables and chairs when using the dining room for alternate events.

For the interior, owners asked the design team to provide the ambiance of a more formal dining room with upgraded finishes, lighting and flooring. “The challenge was to use materials that could stand up to heavy daily use of a boys high school cafeteria,” Wagner says.

Highlights of the design include ceilings that are a combination of two-foot-by-two-foot suspended grid surrounded by dropped gypsum board soffits. “This breaks down the scale of the room,” Wagner says. Wall finishes include high-impact wainscot panels with decorative banding at chair-rail height and again repeated over the cash portal doors. Lighting includes recessed down lights in the soffits and random-patterned linear LED strip lighting. Flooring consists of medium-toned grey luxury vinyl tile.

“All lighting is dimmable LED, and increased insulation was added to the roof and perimeter walls, lowering energy loads for heating and cooling,” Wagner says. “Operable windows were maintained and added at the addition. Also, the kitchen exhaust hood is paired with an energy recovery makeup air unit, taking advantage of the hot air being exhausted to preheat the incoming makeup air.”

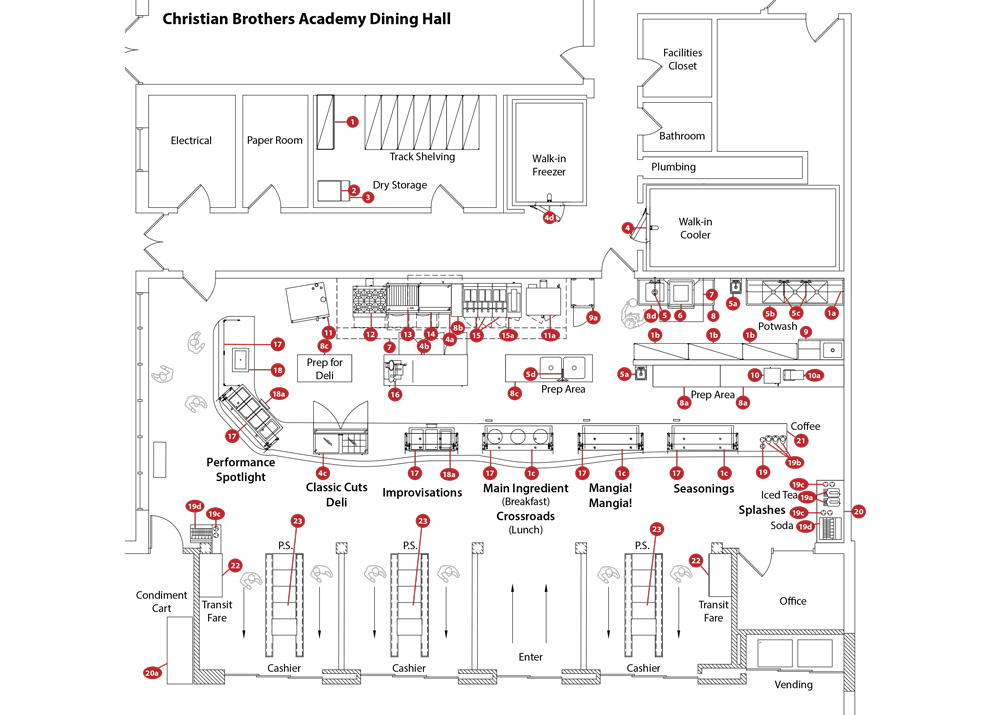

Food Preparation and Serving

“The open-kitchen design allows everyone dining in this facility to see the action,” says Brad LaBel, president of LaBel Foodservice Equipment & Design, Coram, N.Y. The kitchen and serving line include clean stainless-steel equipment with a custom wave-shaped serving line with a quartz top. An overhead soffit follows this wave pattern.

Deep sinks contribute to efficient menu item preparation. “Overall, rebuilding a high school cafeteria during COVID presented a unique set of challenges, adding layers of complexity to an already complex project,” LaBel says. Challenges included constantly changing public health guidelines and regulations, workforce shortages due to absenteeism due to illness or quarantine among installers and manufacturers, supply chain disruptions, and students’ increased demand for grab-and-go menu items and outdoor seating. The project team also encountered factory delays and material shortages. These factors all drove up the cost of the project, LaBel adds.

Deep sinks contribute to efficient menu item preparation. “Overall, rebuilding a high school cafeteria during COVID presented a unique set of challenges, adding layers of complexity to an already complex project,” LaBel says. Challenges included constantly changing public health guidelines and regulations, workforce shortages due to absenteeism due to illness or quarantine among installers and manufacturers, supply chain disruptions, and students’ increased demand for grab-and-go menu items and outdoor seating. The project team also encountered factory delays and material shortages. These factors all drove up the cost of the project, LaBel adds.

In addition, the new dining hall had to be designed to be adaptable to future pandemic threats or other unforeseen circumstances. “When the food-court-style cafeteria was selected, the cafeteria had to be equipped with the latest foodservice technology, such as self-service kiosks, digital menu boards and combi ovens, in order to provide students with a variety of options,” LaBel says.

“We serve an ambitious menu in a short period of time,” says Don Verile, foodservice director and executive chef with SAGE Dining Services, Lutherville, Md. “In my five years here at the school, I’ve established a good rapport with the students. Before I introduce new menus, I ask the boys to write down suggestions at each station. We try to accommodate their suggestions the best we can. Of course, Kobe steaks and lobster aren’t very affordable at a school cafe.”

Staff prepare menu items before each meal service.Every month a special menu created by SAGE encourages students to try different foods, flavors and textures from around the world. “Thanksgiving items like baked apples and spicy cranberry sauce were offered from a Civil War-times menu,” Verile says.

Staff prepare menu items before each meal service.Every month a special menu created by SAGE encourages students to try different foods, flavors and textures from around the world. “Thanksgiving items like baked apples and spicy cranberry sauce were offered from a Civil War-times menu,” Verile says.

While waiting one year for the completion of the new foodservice facility, Verile and his team worked out of a 28-foot mobile kitchen. “We had to premake every menu item in this mobile kitchen and bring it to a conference room that was being used as a servery,” he says.

Today, food arrives at a back door of the foodservice building connected to the parking lot. Staff move menu items into the building, transport them down a corridor and place them into a walk-in cooler, walk-in freezer and dry storage.

In addition to storage areas, the back-of-the-house kitchen contains a dish room with a high-temp, single-rack dish machine and three pot-wash sinks.

Front-of-the-House Open-Display Servery

The main menu preparation takes place at the six serving stations. Staff share equipment, including a double-stacked convection oven for breads and baked goods, three fryers, a flattop, charbroiler, hot food warmer and a double-stacked combi oven for proteins, vegetables, bread and pasta. Each station contains its own hot and cold wells for use as necessary.

Students dine in a room filled with natural light and LED lights. Performance Spotlight caters to the school’s athletes, though anyone is welcome to eat here. Each day’s menu includes a protein, starch and vegetable. “We coordinate the menus here with those at Seasonings station,” Verile says. “For example, if we serve a French dip sandwich at Seasonings then we’ll serve roast beef and potatoes at Performance Spotlight.”

Students dine in a room filled with natural light and LED lights. Performance Spotlight caters to the school’s athletes, though anyone is welcome to eat here. Each day’s menu includes a protein, starch and vegetable. “We coordinate the menus here with those at Seasonings station,” Verile says. “For example, if we serve a French dip sandwich at Seasonings then we’ll serve roast beef and potatoes at Performance Spotlight.”

Staff encourage students to eat vegetables. “High school boys aren’t too fond of vegetables, so I talk to the boys and try to encourage them to eat balanced meals,” Verile says. “SAGE’s philosophy is All Foods Fit. There are no ‘good’ or ‘bad’ foods because we eat many different foods for many different reasons, so all foods have a place on the plate. Our All Foods Fit nutrition philosophy encourages community members to focus on how food supports us holistically, including the physical, social, emotional, mental and cultural aspects. Since about 80% of the students are athletes and win multiple awards annually, most want to eat well so they can continue winning for their teams.”

Students find made-from-scratch soups served at a separate station called Stock Exchange that sits along a wall near Performance Spotlight. Soups stay heated in warmers.

Classic Cuts Deli offers breads freshly baked in the combi ovens and meats house-roasted in the combi oven for customized sandwiches and accompaniments. Students give their orders to a staff member who combines ingredients that are on display in a refrigerated rail with a glass top that not only covers the ingredients but also can be lifted up and turned into a food shield.

Improvisations features mixed green salads and different wraps each day. This station offers salads and wraps. On Tuesdays and Thursdays the culinary team offers an all-you-can-eat pasta bar here. Ingredients stay cold and hot as necessary in wells.

Crossroads staff use the charbroiler, flattop and combi ovens to cook menu items for lunch such as burgers, hot chicken wraps and quesadillas. “Nearly 40 quesadillas are prepared at each lunch period, placed in the combi oven for 4 minutes at 410 degrees with 60% humidity, and they come out as if they had been grilled on a flattop,” Verile says.

Crossroads also features bacon cheeseburgers and rodeo burgers on Tuesdays and chicken fingers and chicken and waffle sandwiches with bacon jam on Fridays. The station becomes Main Ingredient for breakfast. Staff use the same equipment to prepare pre-made egg and cheese sandwiches with bacon, sausage or pork roll, all served on a hard roll or gluten-free bread. Other menu items here include house-made pancakes, French toast sticks, house-made muffins, hash browns and breakfast burritos.

At Mangia! Mangia! staff prep all ingredients to make menu items such as baked ravioli with meatballs and marinara sauce as well as Cajun chicken fettuccini Alfredo. Staff bake these pasta and Mediterranean dishes in the combi ovens and place them on the station’s heated thermal countertop.

Equipment placement allows staff easy access to hot and cold menu item preparation, as well as sinks and front-of-the-house service.Staff also prepare approximately 30 pizzas at this station daily. They use the combi ovens to bake the pies. “About three to four 16-ounce pies bake in this oven for about four minutes before we take them out of the oven, slice them into six slices and place them on peels and stones for students to take,” says Verile.

Equipment placement allows staff easy access to hot and cold menu item preparation, as well as sinks and front-of-the-house service.Staff also prepare approximately 30 pizzas at this station daily. They use the combi ovens to bake the pies. “About three to four 16-ounce pies bake in this oven for about four minutes before we take them out of the oven, slice them into six slices and place them on peels and stones for students to take,” says Verile.

Seasonings station features made-to-order burritos, made-to-order omelets and hot sandwiches such as French dips and roast turkey club on a croissant. Staff cook proteins in multiple areas in the combi ovens, convection ovens and charbroilers. The cold ingredients sit in hammered stainless-steel bowls that stay cold sitting on ice. Hot food sits on hot plates and in a decorative stainless-steel roasting pan. Staff assemble the sandwiches and place them in dishes and on thermal trays for students to take.

Students take their beverages, including juice, tea, coffee, soda and bottled water from Splashes station.

P.S. station features sweet and savory baked goods, pastries, yogurt, fresh fruit, ice cream and house-made chocolate milk. This area resides next to Transit Fare, where two cashiers stand on either side of lines so they can quickly scan in codes placed on menu items. “Parents whose kids use MyKidsSpending debit system or cash have access to the information indicating which menu items were scanned,” Verile says. A total of six cashiers work at each lunch period.

“The redesign and new build of the CBA student dining hall was a major undertaking, but it was a success,” LaBel says. “The new cafeteria is a modern and inviting space that provides students with a variety of dining options. The project was a testament to the hard work and dedication of the design team, as well as the support of the CBA administration and community.”

About the Project

Opened: Sept. 8, 2023

Scope of project: Servery, dining room, back-of-the-house kitchen

Equipment investment: $545,000

Website: cbalincroftnj.org

Don Verile uses the hand blender to puree a cream of mushroom soup.Student enrollment: 825

Don Verile uses the hand blender to puree a cream of mushroom soup.Student enrollment: 825

Size:

- Back of the house, including cashier stations: 3,300 sq. ft.

- Expanded servery, kitchen and dining area: 5,900 sq. ft.

- Seats: 385

- Daily transactions: 1,600

Menu concepts:

- Stock Exchange — house-made soups

- Performance Spotlight — athlete’s station with a protein, starch and vegetable daily

- Classic Cuts Deli — freshly baked breads, house-roasted meats, toppings for made-to-order sandwiches

- Improvisations — chef-crafted and build-your-own salads and wraps with house-made dressings

- Main Ingredient — breakfast concept

- Crossroads — burgers, quesadillas, hot chicken wraps

- Mangia! Mangia! — pizza, pasta and Mediterranean fare

- Seasonings — build-your-own sandwiches

- Splashes — beverages, including juice, tea and coffee

- Transit Fare — sweet and savory baked goods, pastries, yogurt, fresh fruit and house-made chocolate milk

- P.S. — dessert and snacks

Hours

- Breakfast: 7:30 a.m. to 9:30 a.m.

- Lunch: 10 a.m. to 2 p.m.

- Snacks: 2 p.m. to 3 p.m.

Staff: Director and six full-time equivalents

Total project cost: $3.4 million

Equipment investment: $536,000

Key Players

Owner: Christian Brothers Academy

CBA president: R. Ross Fales

CBA chief financial officer: Brendan McLoughlin

CBA principal: Neal Begley

Foodservice contractor: SAGE Dining Services, Lutherville, Md.

SAGE foodservice director and executive chef: Don Verile

SAGE sous chef: Jonathan Cavaliere

Cashier/SAGE ambassador: Donna Susino

Architect: Kellenyi Johnson Wagner (KJW), Red Bank, N.J.: Eric Wagner, AIA, principal in charge; Richard Kane, AIA, project manager; George Nick, production team member

Interior design: KJW: Andrea Kunyz, architectural designer; Marianne Ziegler, interior designer

Foodservice design: LaBel Foodservice Equipment & Design, Coram, N.Y.: Brad LaBel, president

Equipment dealer: LaBel Foodservice Equipment & Design

Contractor: Shorelands Construction, Monmouth Beach, N.J.