Getting the dish room layout right leads to good food safety practices and better flow of clean dishware through the kitchen.

Tim TrujilloWhile operators from every segment require some form of warewashing, it can be easy to ignore this area or treat it as an add-on since it’s unappealing and doesn’t generate any revenue. It also contains some very expensive equipment.

Tim TrujilloWhile operators from every segment require some form of warewashing, it can be easy to ignore this area or treat it as an add-on since it’s unappealing and doesn’t generate any revenue. It also contains some very expensive equipment.

But operators ignore it at their peril because a warewashing area that doesn’t function properly will affect the entire business in a negative way. “If you don’t appreciate a dish room, you just don’t understand it,” says Tim Trujillo, principal at Innovative Foodservice Design Team in Tampa, Fla. “They’re dirty and noisy but are an essential part of any facility. As far as them not generating any revenue, that’s true, but they do generate a lot of labor so should be designed for the labor.”

When designing warewashing spaces, they need to be in harmony with the rest of the facility, Trujillo says. “We have to make them as efficient as possible.”

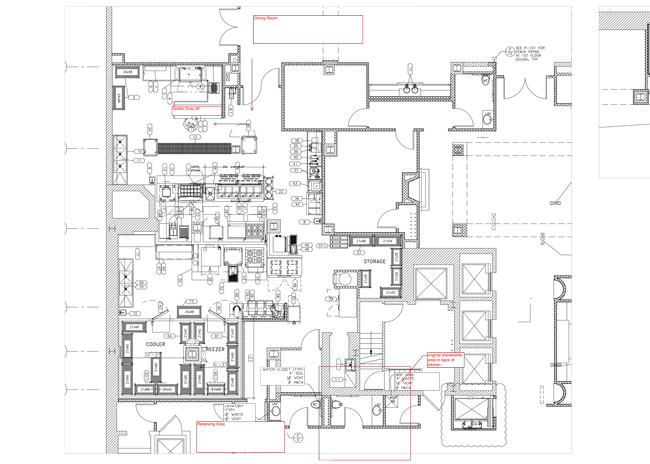

Brad LaBelBrad LaBel, president, LaBel Foodservice Equipment & Design, Islandia, N.Y., recently redesigned a huge assisted living facility in New Jersey with more than 300 beds. “The dishwashing area was in completely the wrong place, furthest from the door the waitstaff come through,” he says. “It’s a waste of labor; it’s a waste of time.” He relocated the dishwashing area to be much closer to the dining room and the entrance/exit to the kitchen.

Brad LaBelBrad LaBel, president, LaBel Foodservice Equipment & Design, Islandia, N.Y., recently redesigned a huge assisted living facility in New Jersey with more than 300 beds. “The dishwashing area was in completely the wrong place, furthest from the door the waitstaff come through,” he says. “It’s a waste of labor; it’s a waste of time.” He relocated the dishwashing area to be much closer to the dining room and the entrance/exit to the kitchen.

Location, Location, Location

The placement of the warewashing area depends 100% on the type of operation. In a noncommercial facility such as a college campus, dish rooms typically operate near a dining hall’s exit so students can self-bus their plates on the way out. “That way, they’re connected to the back of house and the front of house,” says Trujillo.

Setting up bins to allow customers to do their own scraping can be a good idea, LaBel adds. “Dishes go to into the dish room a little cleaner, which helps on the labor side,” he says.

Because it lacks a certain visual appeal that stimulates the appetite, warewashing areas tend to be out of sight, and the further they are from public spaces, the less customers will hear the action. “But that’s in contradiction to where it’s best placed,” Trujillo says. “Bussers in restaurants need to be able to drop stuff as soon as possible so they’re not walking through the kitchen.” So ideally, he says, “you have the dish room just on the inside of the kitchen doors, and hopefully it’s concealed and has walls around it to block the noise and light.” Another thing to consider, he adds, is placing the dish room near to the dock since it will generate a lot of waste.

The area leading to the dish room and kitchen from the dining area should be at least four feet wide to keep soiled dishes away from plates of food, Trujillo says, and the drop-off spot for bussers bringing back dirty dishes should ideally be just inside the door. “The more convenient you make that drop-off, the more efficient bussers are going to be. You don’t want them coming deep into the dish room. Your dish room staff will be on the other side of that drop-off table, and there shouldn’t be any crossover traffic,” he says.

And warewashing areas need two doors if employees are passing each other with soiled and clean plates. Place the doors next to each other, says LaBel, to allow employees to travel in different directions. This of course isn’t necessary if food goes out in a different direction.

Good warewashing design includes space to handle the accumulation of dishes that the dining room will produce.

Good warewashing design includes space to handle the accumulation of dishes that the dining room will produce.

Size Does Matter

Dish rooms can’t be too large, in Trujillo’s opinion, but they are frequently too small. The size of the dish room should depend on how many dishes come through, especially at peak times, and what type of service the foodservice operation offers. A hotel banquet with eight plates per guest per meal will require a much larger warewashing area than a restaurant where customers use one plate, he points out. A good benchmark, he says, is if the warewashing room can process 80% of seating capacity.

An operation’s warewashing area needs to be able to handle the accumulation of dishes the dining room will produce. There needs to be space for soiled dishes as well as racks for glassware above that area to save space. Staff can fill these areas simultaneously, and if the dish room isn’t large enough, there tends to be a lot of extra breakage, which leads to “a lot of wasted money,” says LaBel.

Kristin SedejNot allowing enough space for dirty dishes to accumulate is one of the biggest mistakes foodservice operators make in their warewashing areas, agrees Kristin Sedej, principal and owner of S2O Consultants in Chicago. Another mistake: placing the machine in the wrong location within the room, so it’s inefficient to get the dirty dishes into it and the clean dishes out.

Kristin SedejNot allowing enough space for dirty dishes to accumulate is one of the biggest mistakes foodservice operators make in their warewashing areas, agrees Kristin Sedej, principal and owner of S2O Consultants in Chicago. Another mistake: placing the machine in the wrong location within the room, so it’s inefficient to get the dirty dishes into it and the clean dishes out.

Know what’s coming into the dish room, says Sedej. If big carts come back, allow space for them. Instead of following the usual metrics about how many racks per hour the dishwasher can handle, she says, a more important factor is how many people work in the dish room because a dish machine’s efficiency is predicated on someone loading and unloading it. If that information is not yet available, Sedej recommends basing the size of a warewashing area on the menu type, how many people the operation expects to serve and how many dishes are likely to come back at any one time.

Typically, the warewashing space should take up about 20% of the kitchen and use about 18% of the energy, Trujillo says.

Additional Components

A three-compartment sink is a must for warewashing, says Trujillo, who believes it’s best placed in the kitchen if there’s room since it’s used for the large pots and pans that come directly off the cookline.

These pots and pans often need washing before meal service starts, Trujillo says, especially in a hotel setting. “But people think a three-compartment sink, because it’s a dishwashing component, should go with the dishwasher,” he explains. Many locations, however, don’t have the space to connect it to the cookline.

As for the sink itself, allow room at each end for the accumulation of dishes and for clean storage, says Trujillo.

It’s vital that the three-compartment sink be big enough, Sedej warns. Operators need to be able to submerge their largest items, including sheet pans, in their sinks.

Another element to consider adding to a warewashing area is a scraper, “which we’re going to recommend at every opportunity,” Trujillo says. Scrapers can shorten the amount of time warewashers have to run, he adds. “They’re a capital expense but not a labor expense.” Sedej describes a scraper as a recirculating system used to scrape dishes. Leftover food goes into a basket, which an employee empties several times per shift.

When working with conveyor and flight-type machines, Sedej suggests adding a prerinse unit to drastically reduce water usage. For very dirty dishes, machines circulate water and dump it out, then refresh until the plates are clean. Adding a prerinse at the beginning may eliminate such repetitions, she points out. Prerinsers require an additional 24 to 36 inches of dish room space and can be used instead of a scraper.

LaBel is also a proponent of prerinsing, particularly for large hospitals or catering facilities, “especially if food dries on plates because it’s sat for a while, like in an assisted living facility or nursing home.” Prerinse units aren’t really necessary for restaurants, he says, since plates are usually washed quickly.

Another nice-to-have, Sedej says, is a trough belt conveyor, particularly in the case of high-volume locations. This is a conveyor with a trough with employees standing on each side, scraping dishes, while water sprays the food into the troughs. “It’s large-volume scraping,” she points out.

She also recommends adding blowers to the end of warewashing machines in locations that wash a lot of plastic, which dries very slowly, otherwise the flow will be interrupted, she points out. These work with conveyor and flight-type machines.

LaBel also recommends blowers for larger operations and catering to help prevent streaks, especially on glasses.

Including racks for glassware above the area is one way designers save space.

Including racks for glassware above the area is one way designers save space.

Following Flow

Good flow is vital to the smooth and efficient operation of a warewashing area. The flow, says LaBel, “is all about the kitchen layout and walking into the kitchen so you’re dropping off in a proper sequence. You want to drop off left to right or right to left — you don’t want to backtrack. It’s all about steps –— the fewer steps servers or bussers take, the better, as well as dish room staff.” In a perfect setting, he adds, the bussers come in one door and go out of the other.

It’s important to realize efficiencies with the equipment as well as flow and labor, Trujillo says. “You want to have dishes flow easily from the point of drop-off through the machine and to clean storage,” he says.

The original location for the dishwashing area at this assisted living facility in New Jersey was less than optimal, says Brad LaBel, president of LaBel Foodservice Equipment & Design in Islandia, N.Y. As this floorplan indicates, the location was far away from the entry point for waitstaff. To improve flow, the dishwashing area was relocated closer to the kitchen’s entry and exit points.

The original location for the dishwashing area at this assisted living facility in New Jersey was less than optimal, says Brad LaBel, president of LaBel Foodservice Equipment & Design in Islandia, N.Y. As this floorplan indicates, the location was far away from the entry point for waitstaff. To improve flow, the dishwashing area was relocated closer to the kitchen’s entry and exit points.

Purchasing Considerations for Warewashers

Which warewasher best suits a foodservice operator varies by application. Here are some considerations to weigh when purchasing this equipment:

- Since different wares have distinct washing requirements, operators must determine what they intend to wash in order to specify the correct unit.

- Consider water softness or hardness, which contributes to lime and scale buildup. This can result in the need for more detergent during the wash cycle.

- Assess throughput speed. This will determine how fast the system can wash the items required. The bigger the warewasher and the faster it runs, the more efficient it will be.

- Consider the costs associated with the many consumables that relate to warewashing, such as detergent, rinsing agents and other chemicals.

- Also consider energy consumption and water usage. Energy Star-rated warewashers may save money over time.

- If an operator plans to wash a variety of items in the unit, look at the model’s flexibility. When the ability to wash varied loads that are intermixed becomes important, consider a system that offers random loading capabilities.

- Ergonomics represents another factor when specifying warewashers. Consider how employees will load and unload the unit.

- Take into account the space constraints for this equipment, keeping in mind that it may be best to purchase a unit that is larger for increased efficiency, flexibility, capacity at peak periods and future expansion of the operation.After the purchasing piece comes the maintenance part. Manufacturers recommend cleaning dish machines after every shift since flushing the water removes accumulated soil from the machine, which in turn improves washing performance and reduces detergent usage. This practice also preserves the longevity, sanitation and cleanliness of the machine.A variety of factors may contribute to a foodservice operation’s decision to replace a warewasher. The results of the unit are a key indicator that the warewasher is not operating at 100%. If items are not being cleaned and sanitized properly, this may be an indicator that wash and/or rinse arms are wearing out. Also, if the warewasher’s controls are not operating properly or pump pressure is lost, consider replacing the unit.

Another sign that it might be time to consider replacing this type of equipment is when the tank leaks, which may signify that the welds are giving out. In any of these cases, the warewasher may need to be retired.

Three additional tips to extend the service life of a warewasher: regularly drain and clean flight and rack machines as well as continuous pot and pan washing systems; depending on usage and water quality, clean wash and rinse arms weekly or as necessary; and keep pumps and fans properly lubricated.