Dawn Manor attracts guests looking to experience history in a unique setting.

Before it became a themed restaurant in the Wisconsin Dells area, Dawn Manor was a 19th-century estate in the abandoned village of Newport, Wis. Purchased in 1855 by Abraham Vanderpoel, a friend of Abraham Lincoln and a signer of the Wisconsin Constitution, the property sits a few miles from what became Mirror Lake after a dam was created.

In 1945, George Raab, a famous painter, and his wife Helen purchased the house. Dawn Manor was kept in the Raab family until George Raab III, Helen’s great grandson, sold it to Uphoff Ventures, owned by Steve and Linda Uphoff, in 2018. Despite Steve Uphoff’s ownership of various business assets and restaurants across the country, Dawn Manor was especially personal to him. Six generations of the Uphoff family have lived in the Dells since 1873, and Steve, CEO of Uphoff Resorts with Luxury Estates division, grew up across the street from Dawn Manor. He invested in Dawn Manor to share his fond memories of this historic, one-of-a-kind house with the public.

Photos by Bill Zeigler

Photos by Bill Zeigler

In 2022, Dawn Manor was deconstructed to its boards, and the flagstone was put on pallets and placed in storage for preservation until Uphoff secured the land on which to build. Two years later it was reconstructed on the shores of Mirror Lake, just a few miles from its original location. In 2025, the Victorian-inspired Dawn Manor opened as a restaurant with two main kitchens and five themed dining rooms, each offering a glimpse into the character and history of the rooms, along with a speakeasy bar and wine room, secluded dining rooms and an American restaurant. Reconstructing Dawn Manor on a new location required a multidiscipline team, including investor Uphoff and project partners, including ADCI for architecture and interior design, Boelter for kitchen and interior design and Morrissey Hospitality for foodservice management.

“One of the most remarkable aspects of this project is that the building itself is an artifact,” says Cherie Grutzmacher, NCIDQ, CID, CFSP, interior design and furnishing specialist, Boelter. “Every effort was made to reuse and reconstruct original elements wherever possible. The structure was fully deconstructed and rebuilt on a grid system crafted by skilled Amish artisans. Inside, authentic 1800s materials from the original Dawn Manor were carefully integrated, including staircase components such as newel posts, spindles and cut string supports, along with vintage doorknobs, hinges, and stained glass.”

Each dining room has a distinct historic character. All showcase unique artifacts and curated displays, transforming the space into a mini museum. Dining rooms include The 1855 Room, The Frank Lloyd Wright Room, The Haunted Room, The Lincoln Room and The Raab Room. Dawn Manor also houses The Wine Cave, Vanderpoel Bar and Uphoff’s Rotunda, which is styled like a Prohibition-era speakeasy.

“Tying all the rooms together to create a cohesive design throughout, designers used a cohesive design language and modular furniture, which allows for smooth transitions between private dining events, regular service and seasonal changes without the need for additional staff or reconfiguration time,” Grutzmacher says.

Designers selected ash wood stained in a deep, dark tone, used heavily during the 1800s, Grutzmacher says. “Ornamental cast iron table legs, designed as reproductions of vintage styles but equipped with modern auto-leveling features, ensure the tables remain uniform and functional for a variety of event configurations.”

The Raab Room brings bold color and artistic inspiration to the table, modeled after Dawn Manor’s eccentric former owners, Helen and George Raab. Photo by Megan Elizabeth Photography

The Raab Room brings bold color and artistic inspiration to the table, modeled after Dawn Manor’s eccentric former owners, Helen and George Raab. Photo by Megan Elizabeth Photography

Project Challenges

Historical projects often bring gargantuan challenges for the design team. “Having worked on historic buildings in the past, I’ve often designed custom pieces to complement the architectural tone and heritage of the space,” Grutzmacher says. “However, when we received the cost analysis for the first round of furniture selections, it became clear that the budget wasn’t prepared for made-to-order, period-inspired pieces from the manufacturer we typically use for our private country club projects.”

Grutzmacher and her team turned the challenge into a creative design opportunity. They sourced many of the chairs as off-the-shelf options, customizing them using in-house faux leathers and nailhead trims. “This allowed us to create modern interpretations of furniture designs from the Neoclassical period and the mid-to-late 19th century without exceeding the budget,” she says. “We also requested high-density foam for the seat cushions so that the plywood seat structure would offer better comfort for the guests, an affordable upgrade that made a noticeable difference while keeping costs in check.”

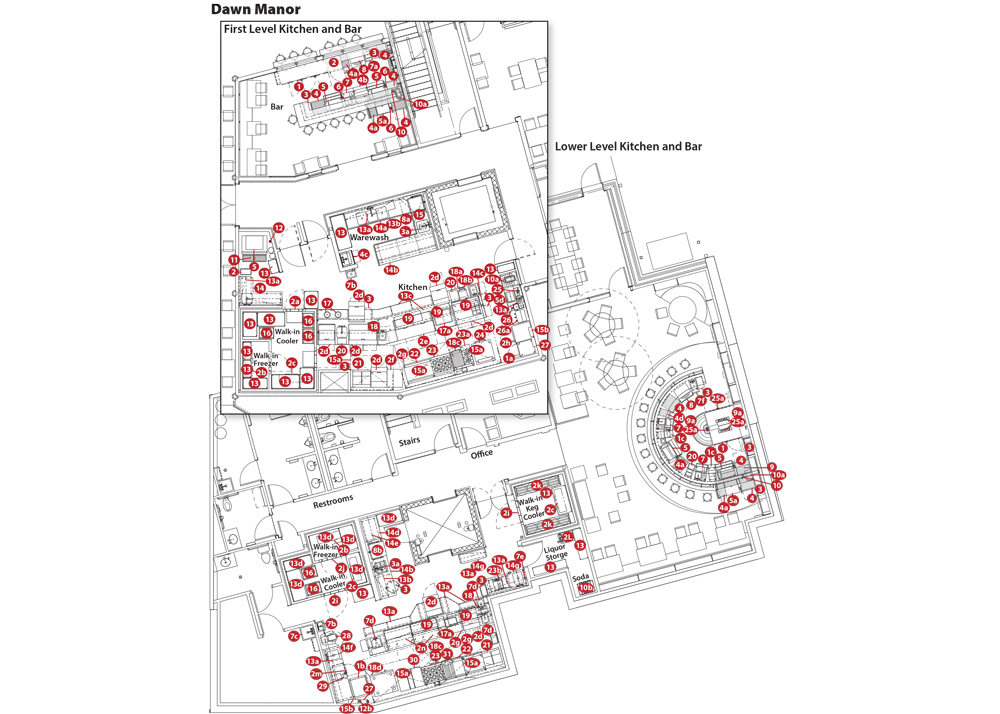

Strategic operational design was also imperative. “Dawn Manor was technically a new build, with key elements of the existing structure incorporated,” says Blake VanDerBosch, project manager for foodservice design, Boelter, Minneapolis. “Fitting two high-output kitchens, five dining rooms and two bars into the overall footprint was very challenging. Every inch of space was accounted for in the foodservice design and the furniture layout to achieve the desired seating count while still working within the design narrative.”

Creating operational efficiencies while maintaining premium guest experiences is always a challenge for project teams when designing a restaurant. “With the cost of food, beverage and labor being the business’s largest expense centers, it was imperative to focus on how to reduce steps in service and effective kitchen and bar execution,” VanDerBosch says.

One of the resolutions was to find an innovative way to manage vertical flow between levels. For example, freight elevator access allows daily prep staff to restock from the prep kitchen on the basement/lower level to the upper-level main kitchen. The design team installed two strategically located dual expo stations to account for the spread across multiple levels. “This allows the kitchen to send food to multiple dining rooms efficiently, without adding extra labor for food runners or sacrificing food temperature and presentation,” VanDerBosch says. The team installed mirrored prep line setups to allow for menu consistency while maintaining flow across two floors. They also installed compact mirrored beverage stations rather than funneling all service; this enables staff to build basic cocktails, pour wine and run soda service without congesting the main guest-facing bar or doubling back across large area.

On each level, designers integrated mini server stations outfitted with POS, glassware, linen storage and ice bins. “These not only saved time but reduced the number of steps required to deliver a polished guest experience, particularly important during peak revenue periods,” VanDerBosch says.

In addition, in the back of the house, keeping distance between prep and plate service, designers installed kitchen display systems to prevent delays and keep timing tight across levels. Cross-trained teams rotate between kitchens to maintain consistent quality and reduce knowledge silos.

The 1855 Room honors the spirit and sophistication of the original Dawn Manor estate.

The 1855 Room honors the spirit and sophistication of the original Dawn Manor estate.

Deliveries, Storage and Kitchens

“Building a restaurant on a space with three floors of stairs and multiple rooms demands more than just smart aesthetics, it requires logistical precision and creative planning behind the scenes,” says Keith Reardon, vice president of operations, Morrissey Hospitality, which provides the culinary management. “With two kitchens split across upper and lower levels, our team had to rethink traditional receiving, storage and production flows to ensure efficiency, food safety and consistency in quality.”

The property has a kitchen on the lower level, designed to support prep cooking and to serve Uphoff’s Rotunda. It also has a main-level kitchen designed to support the main level and second-floor dining spaces.

“In both kitchens, operational efficiency was driving the foodservice design process. From the walk-in coolers to the prep areas to the cookline, flow was optimized in both kitchens to limit steps and cross traffic and to create efficient server pickup stations,” Reardon says.

Lower Level cooking ovens and cooking line

Lower Level cooking ovens and cooking line

Deliveries arrive at a lower-level loading area, timed strategically during nonpeak hours due to spatial constraints. Staff sort, inspect and move menu ingredients into the appropriate storage zones. “This is all within a tightly choreographed system to avoid congestion and maintain product integrity,” says VanDerBosch.

Lower-level storage includes three walk-in coolers. One cooler, located closest to the lower-level kitchen for direct prep access, holds raw proteins such as beef, poultry, pork and seafood. Another cooler, centrally placed in the lower kitchen for shared access between cold prep and both kitchens, contains produce such as leafy greens, chopped vegetables and herbs, and dairy including milk, cheese and eggs. The third walk-in, also centrally placed, stores prepared house-made sauces, dressings, prepped garnishes and batch items, and holds bulk prepped items for use on the hot line.

Storage also includes a walk-in freezer positioned with direct access to the lower kitchen and the freight elevator for upper-level kitchen access. It holds frozen proteins, fries, dessert bases, breads and backup inventory. Limited square footage in the compact dry storage area is offset by vertical racking and first-in-first-out bin systems.

In cold production, which takes place primarily in the lower-level kitchen that serves as the prep hub for the building, staff work on stainless-steel worktables with drop-in refrigerated wells to prepare mise en place. They use tabletop food processors to make dressings, purees and sauces, deli slicers to cut meats and cheese, and commercial mixers for batters, doughs and sauces. Staff also use vacuum sealers and sous vide baths for portioning and precision cooking of menu items such as long-bone pork chops and chicken breasts for pot pies. The mise en place, which also includes chopped produce for salads and sandwiches and pre-portioned proteins for grilling and searing, is portioned, labeled and stored in color-coded containers and held in designated walk-ins or line refrigerators depending on whether they are destined for immediate use or backup stock.

The back of the house contains a deck oven, combi ovens, a range and a griddle.Each kitchen supports its own hot line, though hot production is split strategically by menu needs and floor-level service. The main production kitchen on the lower level supports high-volume and more complex entree prep. Staff use double-stacked combi ovens for roasted vegetables, sheet-pan proteins and batch-cooked chicken, pork and fish. They prepare sauces, soups and sauteed menu items on six-burner ranges with ovens; prepare risottos, braised menu items, chili and pasta sauces on a tilt skillet; and make grilled cheese, seared sandwiches and pancakes for brunch on the flattop griddle. They use the three fryers to make fries, chicken tenders, arancini and calamari.

The back of the house contains a deck oven, combi ovens, a range and a griddle.Each kitchen supports its own hot line, though hot production is split strategically by menu needs and floor-level service. The main production kitchen on the lower level supports high-volume and more complex entree prep. Staff use double-stacked combi ovens for roasted vegetables, sheet-pan proteins and batch-cooked chicken, pork and fish. They prepare sauces, soups and sauteed menu items on six-burner ranges with ovens; prepare risottos, braised menu items, chili and pasta sauces on a tilt skillet; and make grilled cheese, seared sandwiches and pancakes for brunch on the flattop griddle. They use the three fryers to make fries, chicken tenders, arancini and calamari.

Upstairs, the kitchen staff prepare menu items to expedite service for the upper-level dining rooms and deck. This kitchen focuses on finishing, reheating and preparing quick cook-to-order items during peak hours and event service.

The cookline here includes convection ovens for baking flatbreads, sandwiches and appetizers, a six-burner range and overhead salamander for finishing sauces and broiling and melting cheese on entrees. The line also contains two fryers to cook fries and other menu items, which eliminates staff moving back and forth to the lower kitchen. A lowboy refrigerator and drawer freezers allow staff to keep quick-access frozen products and finishing ingredients near the line.

Dining Rooms and Bars

Once hot and cold components are prepared at each kitchen, plating occurs on each floor at dedicated expo stations, which contain heat lamps. A kitchen display system tracks timing across both kitchens, reducing lag between courses.

Each dining room has its own distinct historic character, creating immersive experiences. The 1855 Room honors the spirit and sophistication of the original Dawn Manor estate. The Frank Lloyd Wright Room is inspired by the renowned architect and showcases sleek, mid-century style. The Haunted Room adds a playful twist and a hint of mystery to every meal, offering elegance and intrigue for guests. The Lincoln Room channels the timeless charm and honest hospitality of one of the most influential American presidents. The Raab Room brings bold color and artistic inspiration to the table, modeled after Dawn Manor’s eccentric former owners, Helen and George Raab.

Menu items prepared in the kitchens offer shareables such as horseradish deviled eggs, crispy truffle fries, goat cheese-stuffed dates (wrapped in bacon and topped with balsamic reduction), crabcakes, blackened prime rib, Wisconsin cheese curds and a shrimp tower. Menus also include soups, salads and main entrees such as pan-roasted Amish chicken breast, long-bone pork, potato-crusted fillet of walleye, lobster macaroni and cheese, steak burgers, ribeye steaks and fillets. The brunch menu features BLTs, prime rib cheese steak, burgers, smoked salmon and cottage cheese toast, omelets, crabcake benedict, balderdash hash, flapjacks and French toast.

Uphoff’s Rotunda evokes a bygone era with dark wood and rich textures. Photo by Megan Elizabeth Photography

Uphoff’s Rotunda evokes a bygone era with dark wood and rich textures. Photo by Megan Elizabeth Photography

Uphoff’s Rotunda blends craft, culture and efficiency. Downstairs, Uphoff’s Rotunda evokes a bygone era, with dark wood, warm lighting, curved lines and rich textures reminiscent of a classic speakeasy. Upstairs, the main-level bar opens to natural light, with large windows that spill onto a deck overlooking a wooded area and serene lake. The contrast in ambience is intentional. “Each space serves a distinct vibe while still operating under the same menu philosophy and back-of-house integration,” Reardon says.

Bars focus on speed of service during peak hours, a diverse menu and visual and spatial integration with the bar elements. Compact reach-ins and lowboys are strategically placed to provide easy access to garnishes, syrups and mixers, while modular speed rails reduce staff movement behind the bar. Drop-in ice bins with cold plate integration keep ice production efficient and consistent for craft cocktails and shaken drinks. The bars also contain compact glass washers, space-saving draft towers to accommodate both standard beer taps and a rotating selection of draft craft beers, and soda gun and dream soda (an in-house soda) draft lines.

Each bar contains dedicated, custom-designed, cocktail-first workstations for high output with minimal staff movement. The cocktail draft system was developed in partnership with Tattersall Distillery. Bars also feature build-and-shake stations for cocktails and dual-zone wine coolers. “By aligning equipment with our beverage program and tailoring stations to both labor realities and creative goals, we’ve built a front-of-house operation that performs exceptionally well and inspires innovation behind the bar,” Reardon says.

Photo by Megan Elizabeth Photography

Photo by Megan Elizabeth Photography

Dishwashing and Sustainability

“We realized early on in the design process that Dawn Manor’s dual-kitchen setup would demand two fully functional dishwashing areas, one for each kitchen,” says VanDerBosch. “Dishwashing is often treated as a back-of-house afterthought, but for us, it was a critical component of the operational efficiency, cleanliness standards and sustainability efforts.” All dishes and cookware flow through a defined dirty-to-clean path, reducing cross-contamination and helping meet HACCP compliance standards.

A fryer and refrigerated rail support production.This setup ensures a clean separation between soiled and sanitized items, supports a rapid turnover of dishes during peak hours, and makes efficient use of a very tight footprint. “By designing two dish areas that are right-sized for their roles, we avoided backlogs, minimized cross-floor dish movement, and kept kitchen teams focused on prep and plating,” Reardon says. “The system allows each kitchen to be self-sufficient, yet integrated, supporting high service standards and maintaining cleanliness without wasting steps or space.”

A fryer and refrigerated rail support production.This setup ensures a clean separation between soiled and sanitized items, supports a rapid turnover of dishes during peak hours, and makes efficient use of a very tight footprint. “By designing two dish areas that are right-sized for their roles, we avoided backlogs, minimized cross-floor dish movement, and kept kitchen teams focused on prep and plating,” Reardon says. “The system allows each kitchen to be self-sufficient, yet integrated, supporting high service standards and maintaining cleanliness without wasting steps or space.”

The lower-level kitchen, which handles the bulk of prep and cooking, features a more robust dish area to support the higher volume of cookware, sheet pans, cutting boards and prep tools. It contains a heavy-duty, tall-door dish machine to accommodate full sheet pans, stock pots, hotel-sized pans and larger mixing bowls. A deep, triple-compartment sink supports overnight soaking and manual cleaning of heavily soiled cookware. Staff use mobile soak carts to collect and soak burned-on pans during service to reduce labor during cleanup. Wall-mounted spray arm and foot pedal controls allow for ergonomic, water-efficient prerinsing.

To economize space in the upper kitchen, designers implemented a dish drop zone that is accessible from both service entry points and designed to keep dirty dishes out of guest sightlines and away from the main cookline traffic. Servers and runners deposit used plates, glasses and utensils into a designated area equipped with sorting racks and a prerinse station. A tall-door dish machine processes delicate glassware, full-size dinner plates and serving platters. The area also contains a three-compartment sink integrated with the clean dish table and overhead shelving and racks for immediate air-drying of glassware and clean dishes before redistribution.

Staff assemble menu items before serving.Sustainability is built into the dish operations with composting stations, recycling sorters and Energy Star water-saving dish machines. Energy Star equipment was also used throughout the operation where available. To maximize sustainability, food waste control measures include batch cooking in smart equipment for precise portion control and adjusting batch size to avoid overproduction and minimize waste. The lower-level prep kitchen serves both lines, so purchasing and prepping are consolidated and reduce duplication, spoilage and unnecessary overstocking. Culinary staff use vegetable trimmings and protein scraps in stocks, sauces and daily specials to reduce landfill waste and food cost. A composting program includes sorting and composting pre- and post-consumer food waste. Each dish station has compost bins so staff can separate organic waste from trash. In addition, staff keeep waste logs.

Staff assemble menu items before serving.Sustainability is built into the dish operations with composting stations, recycling sorters and Energy Star water-saving dish machines. Energy Star equipment was also used throughout the operation where available. To maximize sustainability, food waste control measures include batch cooking in smart equipment for precise portion control and adjusting batch size to avoid overproduction and minimize waste. The lower-level prep kitchen serves both lines, so purchasing and prepping are consolidated and reduce duplication, spoilage and unnecessary overstocking. Culinary staff use vegetable trimmings and protein scraps in stocks, sauces and daily specials to reduce landfill waste and food cost. A composting program includes sorting and composting pre- and post-consumer food waste. Each dish station has compost bins so staff can separate organic waste from trash. In addition, staff keeep waste logs.

Other sustainability measures include demand-controlled ventilation for hoods, induction cooking elements in some stations and LED lighting throughout.

“The physical layout of a restaurant kitchen isn’t just about aesthetics or fitting equipment into a defined space, it’s a critical driver of operational efficiency, food quality, employee safety and, ultimately, the bottom line,” VanDerBosch says. “At Dawn Manor, every square foot was planned with purpose, prioritizing labor savings, ease of cleaning and workflow optimization.”

The project team set goals to build a restaurant experience that didn’t just look good but was efficient and sustainable. “We preserved the premium feel guests expect while staying mindful of labor, food and beverage margins. In short,” Reardon explains, “good design became good business.”

Floor Plan

Floor Plan

About the Project

-

Opened: May 23, 2025

-

Scope of project: Complete renovation, including two kitchens, multiple dining rooms, a bar and a speakeasy

-

Website: dawnmanor.com

- Size: 10,608 sq. ft. inside; 2,050 sq. ft. patio

- Seats: 220 in restaurant and rotunda

- Restaurant hours: 3:30 p.m. to 9 p.m., Monday through Thursday; 3:30 p.m. to 10 p.m., Friday; 10 a.m. to 10 p.m., Saturday; 10 a.m. to 9 p.m., Sunday; 10 a.m. to 2 p.m., weekend brunch

- Uphoff’s Rotunda hours: 3:30 p.m. to 9 p.m., Sunday through Thursday; 3:30 p.m. to 10 p.m., Friday through Saturday; 3:30 p.m. to 6 p.m., happy hour, Sunday through Thursday

- Themed dining rooms: The 1855 Room; The Frank Lloyd Wright Room; The Haunted Room; The Lincoln Room; The Raab Room

- Staff: 60 team members

- Equipment investment: $830,000

- Furniture investment: $210,000

Key Players

- Owners: Uphoff Ventures, Chester, Va.: Steve and Linda Uphoff

- Concept development and build V/E, operations management: Keith Reardon, vice president of operations, Morrissey Hospitality

- Executive chef: Justin Draper, Morrissey Hospitality

- General manager: Bill Wilson, Morrissey Hospitality

- Co-culinary director: Jayson Pettit, Morrissey Hospitality

- Architect: ADCI, Appleton,

- Lake Delton and Madison, Wis.: Jason Ryan, AIA, partner and vice president, design

- Interior designers: ADCI: Lauren Johnson, IIDA, senior interior designer; and Boelter Interior Design Services, Minneapolis: Cherie Grutzmacher, NCIDQ, CID, CFSP, interior design and furnishing specialist

- Foodservice design consultant: Boelter, Minneapolis; Blake VanDerBosch, project manager