Menno Haven Retirement Communities, Chambersburg, Pa.

A new central culinary center and cafe serve residents and guests at Menno Haven Retirement Communities, a continuing care retirement community in Chambersburg, Pa. Both the culinary center and cafe reside in the new rehabilitation center, part of Menno Haven’s 5-year, $100 million strategic plan named Project Genesis. The rehabilitation center replaces a portion of the original 1964 nursing home. The larger plan includes the addition of a 35,000-square-foot Resident Life Center, the addition of Memory Care Houses, a new healthcare center and new independent living cottages.

“The idea of a culinary kitchen stemmed from a community master plan that we facilitated and through which Menno Haven positioned its culinary program as a center of excellence,” says Jay Weingarten, AIA, WELL AP, partner at RDG Planning & Design, Omaha, Neb. “A central culinary center allows Menno Haven to concentrate its culinary talent so that a similar quality of food can be delivered across the community and regardless of level of care.”

Central Culinary Center

The central culinary center provides food for 850 independent living residents, 200 personal care residents and 160 skilled care residents in 10 buildings across 2 communities. Prior to this new building and culinary center, each facility contained its own kitchen. Now, staff prepare food in the center and distribute it to satellite kitchens at the facilities where team members finish cooking and assemble meals before service.

This setup — a new central culinary center integrated with cook-chill and sous vide technology — allows Menno Haven’s culinary center to support all five of the retirement community’s food outlets and provide consistent menu items throughout. “This approach was in place of renovating current undersized kitchen spaces that could not sustain new growth that the community needs,” says Matt Schuler, CFSP, director of culinary development, SCOPOS Hospitality Group, Ephrata, Pa.

Sous vide production enables culinary kitchen staff to cool product quickly. Later, staff at the satellite facilities finish the cooking process.

Sous vide production enables culinary kitchen staff to cool product quickly. Later, staff at the satellite facilities finish the cooking process.

The centralized food production is much more efficient than the previous approach, says Jeremy Fry, executive director of Culinary Services, Cura Hospitality, a part of the Elior North America family of companies. “We want to make fresh products that are consistent across the community. Consistency isn’t possible when staff at various facilities are preparing menu items. In addition, we receive revenue only from residents and we feel it is a waste of their money to duplicate food production equipment.”

The culinary center sits inside the rehabilitation center, which was specifically designed to improve the health and well-being of everyone who comes into the building. In August 2019, Menno Haven became the first skilled nursing building to earn gold status from the International WELL Being Institute. “As part of the certification, Cura follows the WELL nourishment standards,” says Fry. “From-scratch food is consistently prepared to optimize health and nutrition, while operating procedures and service levels enhance the overall dining experience.”

Production Flow

Food arrives at the rehabilitation center’s dock. “By locating the culinary kitchen in the rehabilitation center, which is near the entrance to the community, the design team enhanced ease of product delivery and reduced large truck traffic within the community,” Weingarten says.

After receiving deliveries, staff move food down a hallway to the culinary center and place it in dry storage, a walk-in cooler dedicated for produce, another walk-in cooler for dairy and meat, and a walk-in freezer. A staging walk-in cooler that staff use during production sits on the right.

Inside the culinary center, windows provide kitchen staff with a view of the outdoors, a key component of the WELL Building Standard. The facility’s leaders believe this also contributes to the well-being of staff and their subsequent ability to output high-quality meals.

Cold production contains an area with sinks for washing vegetables and vegetable prep equipment. In this area staff clean and cut ingredients such as lettuce and tomatoes for salads and then distribute the prepped items to each facility. In the on-site kitchens, culinary staff combine ingredients to make salads.

Culinary center staff also cut proteins for hot production. Hot food production includes two areas, one for vegetables and the other for proteins. The vegetable cooking side contains a range for cooking small batches of sauces for scalloped potatoes and mac and cheese; a tilt skillet for house-made stocks and sauces for entrees, and rhubarb and apricot glaze for chicken legs; and a combi oven for par-roasting vegetables and potatoes. The protein cooking side contains a range for finishing menu items for the cafe, which operates as Courtyard Cafe, and a tilt skillet for stews and chicken pot pies. Staff use the combi oven to sear house-made deli meats, turkey, roast beef and chicken quarters.

“The combi ovens have been our workhorses,” Fry says. “We use the combis in the central kitchen and at the satellite kitchens. We can manage the entire network by setting controls for all the combis at the satellite kitchens from our office computers or phones. If we have a menu change, we can roll it out to all the facilities at one time by programming the ovens the same way.” The protein cooking area also contains a chargrill to pargrill pork chops, burgers and chicken breasts.

“As a part of the WELL Building Standard, we designed the culinary center so the operating temperature never exceeds 80 degrees F,” Weingarten says. “Our design team had many conversations about how we would achieve this given that there are six exhaust hoods in the space that will provide constant exhaust. We chose to provide precooled makeup air at each hood to ensure that the cooking environments directly under the hoods will maintain a comfortable operating temperature.”

After cooking vegetables and protein to nearly 75 percent done, staff place some of these items into one of two blast chillers to cool them quickly. The ingredients are sent to Courtyard Cafe and finishing kitchens where staff finish them for meal service.

“Keeping HAACP standards is always a challenge when it comes to quantity food prep,” Schuler says. “Using the blast chillers for the production cooklines allowed us to bring down the temps of hot foods at a rapid pace, ultimately allowing us to store those foods safely until ready for disbursement.”

Staff use cook-chill equipment to support menu items they prepare in larger quantities. They use a 100-gallon kettle to prepare soups and sauces for pizza and pasta. Designers left space open for another 100-gallon kettle when an increase in resident population requires greater food production.

After cooking the soups and sauces, staff use an electronic-powered pump station to transfer the food into 1-gallon bags, clip the bags closed and drop them into a water bath with a 75-gallon capacity to cool down. “This allows food to be brought from roughly 180 degrees F to 40 degrees F in 60 minutes or less,” Schuler says. The staging walk-in cooler holds these items before a team member transports them to satellite facilities.

The culinary center also uses sous vide production. “We wanted to be able to cook more in house, so we are now preparing all of our roast beef, pork shoulders for pulled pork, roast turkey, brisket and barbecue pork ribs using sous vide cooking,” Fry says. For preparation of roast beef, for example, staff sear the beef in a combi oven at 575 degrees F for 8 minutes, place it into a blast chiller, add house-roasted garlic and thyme, vacuum pack it with a packager and then place it into a sous vide tank that fits 350 pounds of product, where it cooks for 6 to 8 hours or, for brisket, up to 12 hours.

When proteins reach the proper temperature, the tank stops cooking, drains the hot water using three-inch copper pipes that funnel the liquid into dedicated drainage troughs. Once the hot water drains, the tank receives cold water from a faucet. A circulator moves the cold water in the tank and lowers the product temperature to 35 degrees F. Staff remove the bags of food items from the tank when they return to work in the morning and place them into the staging walk-in cooler. At about 6 a.m., staff remove food items from the bags and either slice the items and package them in airtight containers or keep them whole before placing the chilled food into a 16-foot refrigerated box truck and delivering it to satellite facilities where staff finish the cooking process before serving.

The culinary center also contains a bakery with an 80-quart mixer, an 8-quart mixer, ingredient bins, a pair of low-temperature proofing cabinets, a convection oven and a roll-in rack. Staff package and label baked items and deliver them to satellite facilities. “We send raw cookie dough to smaller memory homes so staff members can bake them on-site and send the smells into the atmosphere,” Fry says.

Staff use mixers to prepare dough and mashed potatoes.

Staff use mixers to prepare dough and mashed potatoes.

The culinary center’s dish room contains pot and pan warewashing machines for cleaning utensils used during culinary center production as well as containers that staff at satellite facilities wash out and send to the culinary center. “We use large hoses and high-pressure sprayers so we can power wash the kitchen,” Fry says.

A dedicated dish room for the cafe handles all the tabletop items.

Courtyard Cafe

An open-kitchen concept in the cafe allows guests to interact with the culinary center team members and experience freshly prepared food. The menus change on a weekly basis and feature seasonal fruits and vegetables from local Chambersburg farms. Although they have a choice of dining in the cafe or ordering room service, Fry encourages guests to sit down and enjoy a meal with others, which promotes socialization and mental health benefits.

The new cafe space encourages residents to dine here and socialize instead of ordering room service.

The new cafe space encourages residents to dine here and socialize instead of ordering room service.

During meal service, staff prepare menu items using a self-contained cooking center, which contains an integrated induction griddle and induction cooker. Staff use a combi oven and rapid-cook ovens to cook a la carte items. An 11-quart drop-in induction rethermalizer holds soups and sauces. A display counter with a chill top holds the fresh produce and cold menu items so residents and team members alike can see the daily offerings. Staff then prepare menu items to order. A beverage area contains equipment to prepare coffee and tea. After staff assemble food, waitstaff deliver menu items to residents and their guests.

The open kitchen enhances the dining experience for residents.

The open kitchen enhances the dining experience for residents.

As Menno Haven continues to house more residents and enhance dining options, Fry and the project design team believe they have established a food preparation system that will continue to bring consistency and high quality to each facility.

Customers at Courtyard Cafe can enjoy scenic views from indoors or sit on the patio and enjoy the outdoors.

Customers at Courtyard Cafe can enjoy scenic views from indoors or sit on the patio and enjoy the outdoors.

About the Project

- Opened: February 2019

- Seats: 40 in Courtyard Cafe

- Average check for paying guests: $7.15

- Total annual sales, projected: $10,000 for paying guests

- Culinary budget for Menno Haven: $6.2 million

- Daily meals/transactions: 200, including residents’ guests

- Menno Haven Retirement Communities: Menno Haven is a nonprofit continuing care retirement community, also called a life plan community, in Chambersburg, Pa. Two communities house 1,200 residents and employ 650 people.

- Scope of project: Central culinary center and cafe

- Size: Culinary center, 4,500 sq. ft., Cafe, 350 sq. ft.

- Hours: Culinary center, 5 a.m. to 1 p.m.; Cafe, 7 a.m. to 7 p.m.

- Staff: Culinary center, 10.8 full-time equivalents; Cafe, 4.4 full-time equivalents

- Total project cost: $20 million for the rehabilitation center, including the culinary center

- Equipment Investment: $1.1 million for both the culinary center and Courtyard Cafe

- Website: mennohaven.org

Key Players

- Owner: Menno Haven Retirement Communities, Chambersburg, Pa.

- CEO: Hugh Davis

- Chief financial officer: David Gentry

- Executive director of culinary services: Jeremy Fry, Cura Hospitality, part of the Elior North America family of companies, Canonsburg, Pa.

- Executive chef: Jeremy Mickey, Cura Hospitality

- Sous chef: Josh Gibson, Cura Hospitality

- Founder and managing director, Cura Hospitality: Mitch Possinger (retired after project completion)

- Managing director, Cura Hospitality: Lisa Schairer

- Architect: RDG Planning & Design, Omaha, Neb.: Scott Pfeifer, principal and Jay Weingarten, AIA, WELL AP, partner

- Interior design for cafe: RDG

- Planning & Design, St. Louis: Lara Slavkin, partner

- Design, consulting and management services: SCOPOS Hospitality Group, Ephrata, Pa.; Andrey Teleguz, principal; Matt Schuler, CFSP, director of culinary development; Austin Sommer,

construction administrator - Equipment dealer: Singer Equipment Co., Elverson, Pa.; Michael Day, national accounts team leader; Brian Ruth, account manager

- Construction: Warfel Construction, East Petersburg, Pa.

Meet the Players

Jeremy Fry, executive director of Culinary Services, Cura Hospitality. Fry joined Menno Haven seven years ago. Previously he worked at another retirement community following graduation from the Culinary Institute of America.

Scott Pfeifer, principal, RDG Planning & Design. Pfeifer joined the firm 29 years ago. Another of his projects is The Woodlands at John Knox Village in Pompano Beach, Fla.

Matt Schuler, CFSP, director of Culinary Development, SCOPOS Hospitality Group. Prior to joining SCOPOS in 2015, Schuler served as a faculty member for The Pennsylvania School of Culinary Arts, as well as a private chef, catering chef and banquet chef for several upscale restaurants in central Pennsylvania.

Lara Slavkin, partner, RDG Planning & Design. Slavkin brings more than 16 years of experience to the Senior Living Interiors team, including previous design experience in higher education sports and recreation.

Andrey Teleguz, principal, SCOPOS Hospitality Group (SHG). Teleguz founded SHG in 2009. Other project locations include Spring Lake Village in Santa Rosa, Calif.; Wavery Heights in Gladwyne, Pa.; and White Horse Village in Newton Square, Pa.

Jay Weingarten, AIA, WELL AP, partner, RDG Planning & Design. Weingarten joined the firm five years ago.

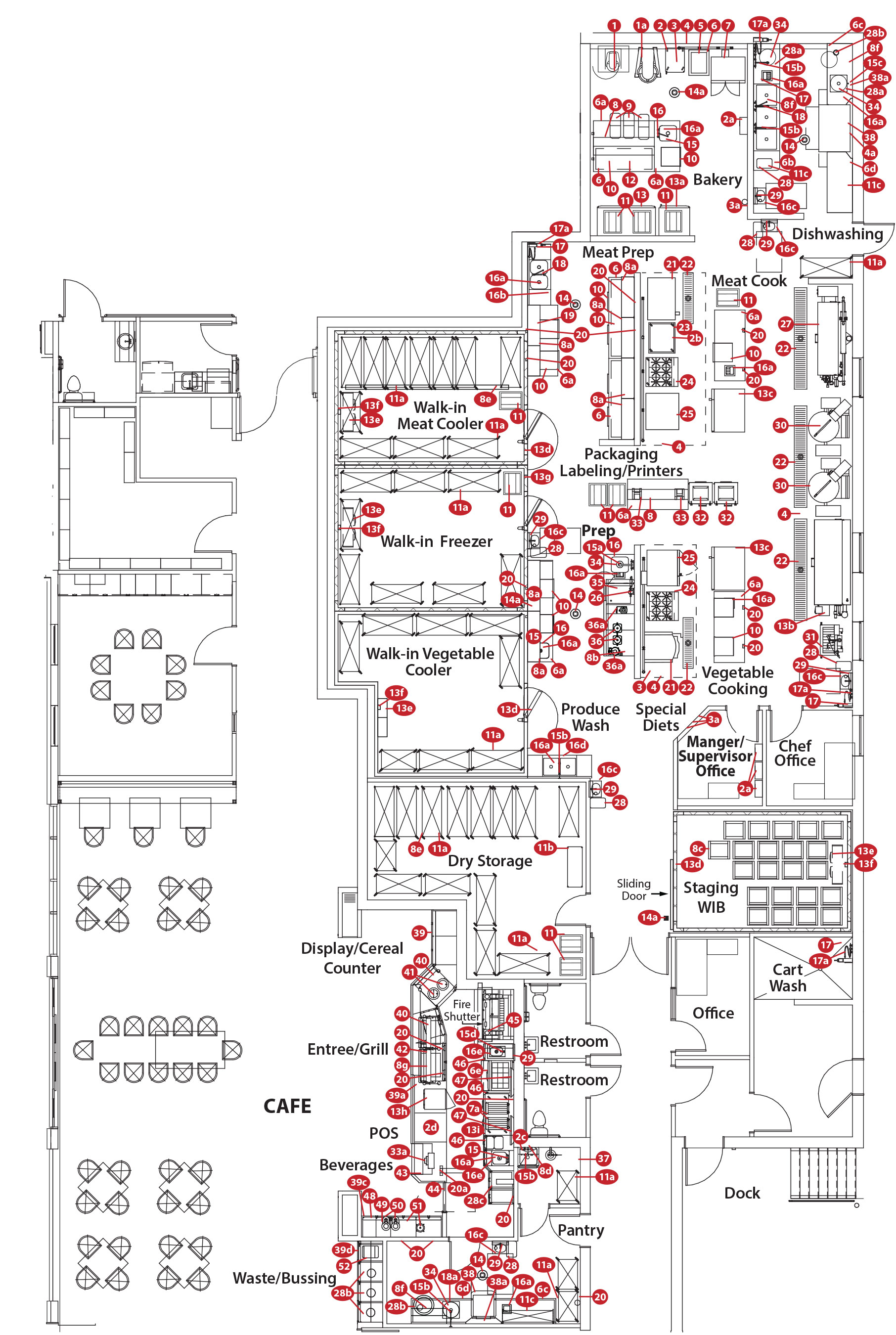

Equipment Key

1. 20-qt. mixer

1a. 80-qt. mixer

2. Low-temp hot holding cabinets

2a. Wall-mounted control cabinet

2b. Charbroiler

3. Fire protection system

3a. Manual fire pull station

4. Exhaust hood

4a. Condensate hood

5. Hot plate w/stand

6. Worktable w/back splash and under shelf

6a. Worktable w/marine edge

6b. 3-bowl dish table w/pre-rinse

6c. Soiled dish table, left-handed

6d. Clean dish table, right handed

6e. Sandwich-prep worktable

7. Convection oven

7a. High-speed oven

8. Double overshelf, nonadjustable

8a. S/s sliding wall shelves

8b. Shelf

8c. Dry storage shelving

8d. Utility shelf

8e. High-density track kit shelving

8f. Tubular rack shelf

8g. Drop-in ceramic glass shelf

9. Ingredients bin

10. S/s drawers

11. Roll-in rack

11a. Polymer shelving

11b. Dunnage rack

11c. Wall-mounted 1-tier wire rack

12. Dough roller

13. Roll-in refrigerator

13a. Roll-in freezer

13b.Product chiller

13c. Blast chiller

13d. Walk-in cooler

13e. Double cooler evaporator

13f. Junction box, heat tape

13g. Walk-in freezer

13h. Undercounter freezer

13i. Undercounter refrigerator

14. Area floor drain

14a. Funnel floor drain

15. Deck-mount faucet

15a. Wall-mount fixing faucet

15b. Wall-mount prerinse faucet

15c. Deck-mount prerinse faucet

15d. Electronic eye faucet

16. Prep sink, weld in

16a. Floor sink

16b. Single bowl sinks

16c. Electronic eye hand sink

16d. Two-bowl sink

16e. Drop-in sink

17. Hose reel

17a. Hose reel accessories

18. Prerinse unit

18a. Prerinse basket w/welded slide bar

19. Food slicer

20. Duplex convenience receptacle

21. Insulated tilt skillet

22. Anti-splash floor trough

23. Heavy-duty charbroiler

24. Heavy-duty range

25. Combi oven

26. Water filter, steam

27. Cooker/chiller

28. Waste bin

28a. Scrap basket

28b. Waste container, 32-gal. w/dolly

28c. Double pull-out waste basket

29. Towel/soap dispenser

30. 100-gal. kettle

31. Pump-fill station

32. Vacuum packing machine

33. POS printer

33a. POS

34. Garbage disposer

35. Convection steamer

36. Blender

36a. Mixer blender

37. S/s 5-foot wall panel

38. Warewasher

38a. Warewashing filter

39. Display counter, millwork

39a. Front counter, millwork

39b. Back counter, millwork

39c. Beverage counter, millwork

39d. Trash counter, millwork

40. Food guard system

41. 11-qt. drop-in induction rethermalizer

42. LED light and warmer

43. Self-serve counter case, refrigerated

44. Dutch door, millwork

45. Exhibition-style cooking station

46. Corner guard

47. Digital menu board

48. Ice and water dispenser

49. Coffee maker and airpots

50. Insultated coffee server

51. Coffee grinder

52. Bus tub