Inspecting and cleaning grease traps and filters is part of ventilation maintenance.

Inspecting and cleaning grease traps and filters is part of ventilation maintenance.

From Thanksgiving through New Years, the holiday season is a flurry of activity for restaurants and commercial kitchens. That makes it really easy for operators and managers to put off some the quarterly preventative maintenance, taxing some of their essential food equipment in the process. Fortunately, foodservice companies can save the day (and season) by offering different planned preventative maintenance packages that take care of everything from deep cleanings and checkups to replacing parts and everything in between.

Here are some potential tasks your service company can perform during the holiday season for customers.

Hot-Side Maintenance

Whether it's a planned PM maintenance package per unit or one that combines several key tasks across all hot-side equipment, a package can be offered a couple of ways. Regardless of which route you pick, your customers will appreciate some cleaning and checkups on vital areas of these units. Below are some piece of cooking equipment and examples of key tasks you can perform as part of a program:

- All units – Check any door gaskets, electrical connections, gas hoses (if applicable), high-limits, temperature probes, thermopiles, thermocouples and thermostats

- Ovens and ranges – Clean any buildup of grease, grime and dust on the exhaust and blower motor fan

- Conveyor ovens and toasters –Check and adjust links in the conveyor belt chains or replace damaged conveyor belts

- Combi ovens – Check the drain lines and gaskets as well as replace old water filters

- Fryers – Change filter paper and/or clean out the built-in filtration system

- Exhaust hoods – Remove and clean grease traps, filters as well as clean the interior and exterior surfaces

- Grills and griddles – Check for cracking and stress damage on the surface or platens

- Steam equipment –Change any water filters and check steam generator, if applicable

Cold-Side Maintenance

From ingredients to ice, planned PM is key heading into the thick of the holiday season. Here are some tasks that you can offer customers on cold-side equipment:

- All units – Check any electrical connections and thermostats

- Refrigeration - Clean the condenser coils, remove and clean all drain pans, check the evaporator coil and replace air or water filters

- Ice machines – Conduct a deliming procedure, inspect the ice thickness probes and replace air or water filters

- Ice cream machines –Check and replace hoppers, augers and O-rings as well as clean the condenser coils, if applicable

Additional Equipment Maintenance

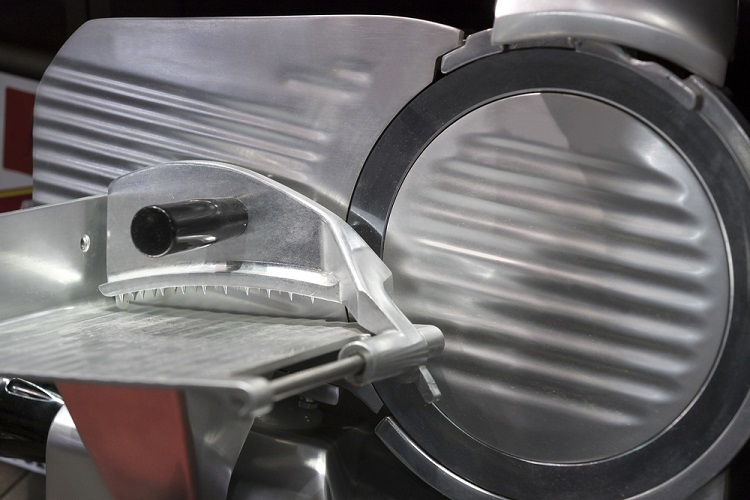

Part of food prep maintenance should include sharpening or replacing slicer blades.

Part of food prep maintenance should include sharpening or replacing slicer blades.

Aside from the hot- and cold-side equipment, there are other vital units should get some love heading into the holiday rush. Equipment like beverage, warewashing and food prep units all need some form of planned preventative maintenance. Below are some tasks you can include in a package for these additional units:

- All units – Check any electrical connections

- Dishwashers and warewashers – Check and replace the curtain, wash arms, O-rings, floats and nozzles

- Beverage machines – Remove ice from the beverage dispenser bins and conduct a thorough cleaning as well as check and replace the water filters

- Coffee machines – Descale the unit and water lines as well as check and replace the water filters

- Food processors – Check the blades to see if needs to be sharpened or replaced

- Mixers – Check the agitators and lubricate the drives, reducers, shaft bearings and other components

- Slicers –Oil the transport and carriage rods and check the slicer blades to see if needs to be sharpened or replaced