A Q&A with Jessica Harrington, principal application engineer, Accurex

Jessica HarringtonQ: Ventilation technology has advanced so systems recognize that cooking is occurring and can also address cooking level intensity. Describe how this works.

Jessica HarringtonQ: Ventilation technology has advanced so systems recognize that cooking is occurring and can also address cooking level intensity. Describe how this works.

Jessica Harrington: Demand-controlled kitchen ventilation systems (DCKV) utilize temperature sensors that sense the amount of heat appliances are giving off. With the Accurex Vari-Flow system, the fans begin operating at 50 percent of full speed. As the temperature climbs, so does the fan speed, until the sensors reach a maximum temperature set point. The Vari-Flow system modulates the speed based on temperature between the min and max set points.

Q: There’s more to this concept than just the temperature sensors and hood controller. Please describe these systems.

JH: When using demand-controlled kitchen ventilation technology the exhaust and make-up air unit that tie into the controller need to have the capability to speed up and slow down accordingly. These fans should be able to reduce airflow by at least 50 percent of their full capacity without any loss in functionality of the unit. One example of this is that a direct gas-fired make-up air unit uses a burner within the unit that requires a certain velocity of air in order to safely operate the burner for heating the make-up air when its cool outside. Accurex make-up air units are capable of reducing airflow more than other manufacturer’s units because we developed a patented barometric bypass damper that automatically keeps the air velocity across the burner consistent as the make-up air units fan speed changes.

Heat sensors automatically reduce energy consumption by reducing fan speeds which decreases electrical, heating and cooling loads.

Heat sensors automatically reduce energy consumption by reducing fan speeds which decreases electrical, heating and cooling loads.

Q: Implementing a smart system means also staying up to date with the latest motor technology. Talk about this aspect of the system.

JH: Electrically commutated motors allow you to reduce your airflow in a compact, easy-to-maintain, more energy efficient way than traditional motors have ever been able to do. Vari-Green® motors are capable of reducing fan speed by 80 percent and require 30 percent less energy to operate. They are basically a motor and variable frequency drive combined into one.

Q: When it comes to DCKV technology, why is it best to select the equipment with the largest capacity in airflow reduction?

JH: A 50% reduction in airflow at times of minimal cooking results in 88 percent electrical savings, with additional energy saved as a result of reducing the amount of heated and/or cooled make-up air brought into the space. Not to mention, reducing the fan speeds leads to increased sound comfort for the

patrons and staff as well.

Q: How can operators further reduce maintenance with added automation?

JH: Consider self-cleaning hoods such as the Accurex AutoScrubber that take care of washing both sides of the filters in-place daily so your staff doesn’t have to. You decide the optimum washing schedule for your restaurant’s operation, and we’ll program it right into the controls.

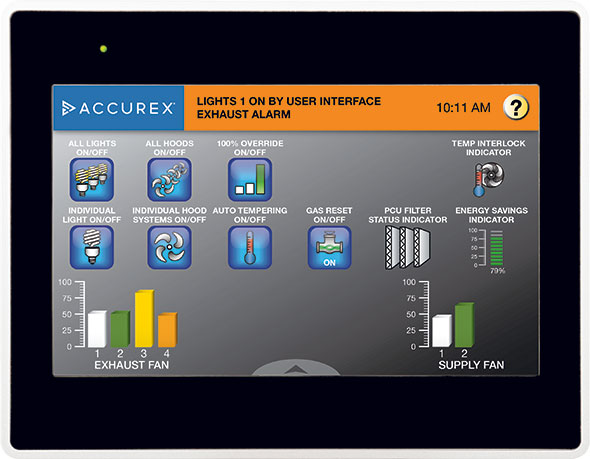

Effectively monitor cooking operation for quick airflow adjustment with the touch screen.

Effectively monitor cooking operation for quick airflow adjustment with the touch screen.