Chartered on May 21, 1882, Capital City Club (CCC) in Atlanta is one of the oldest private social clubs in the South.

Photos by Brian Crumb, Brian Crumb ProductionsThere are actually three different Capital City Club locations: one sits in downtown Atlanta, another in Brookhaven and the third in Crabapple. The shared purpose of each clubhouse remains as it began back in 1882 with the first clubhouse: “A social organization to promote the pleasure, kind feeling and general culture of its members.” As membership has grown and continues to become more sophisticated about services, including dining and catering, the club has embarked on renovations to provide members what they expect with outstanding service.

Photos by Brian Crumb, Brian Crumb ProductionsThere are actually three different Capital City Club locations: one sits in downtown Atlanta, another in Brookhaven and the third in Crabapple. The shared purpose of each clubhouse remains as it began back in 1882 with the first clubhouse: “A social organization to promote the pleasure, kind feeling and general culture of its members.” As membership has grown and continues to become more sophisticated about services, including dining and catering, the club has embarked on renovations to provide members what they expect with outstanding service.

“CCC’s coat of arms consists of a shield, crest and motto, ‘Carpe Diem.’ And that motto really personifies the club’s spirit,” says Matt McKinney, who served as CCC Brookhaven’s chief operating officer and general manager for more than 18 years. His tenure included the most recent multiphase renovation/addition project that spanned just more than a decade, ending in 2024. McKinney retired in February 2025; Eric Leland is now the chief operating officer and general manager at CCC Brookhaven.

CCC Brookhaven had undergone many expansions and renovations over the years. In 1927, a new clubhouse for Brookhaven was authorized, and construction was completed in October 1928. The basic front architectural elements of that structure still stand, although the full clubhouse has been expanded and renovated many times since.

Phase 1 of the most recent multiphase renovation/addition project, which occurred from June 2013 to November 2013, included the renovation of the family dining area and patio areas with high-end finishes. A new exhibition cooking area was added along with a built-in buffet for the family dining area.

Phase 2, from August 2015 to June 2016, included demolition and construction of three swimming pools, a new fitness building and a covered outdoor patio with a fireplace and pool area. The snack bar was renovated, and a new Tuscan bar was designed and added to the main dining room with a wine room.

Phase 3 began in June 2019, before the pandemic, with construction taking place from July 2022 to March 2024 — including an addition to the historic building; a remodel and expansion of the primary kitchen, bakery and employee dining/break room; a remodel of The Overlook adult restaurant and bar and the Refreshment Center cafe; and a vertical expansion and interior decoration of The Belvedere ballroom and bar. The project also included a remodel and refreshment of foodservice equipment for the men’s and women’s lounges; and a remodel of the fitness area and complete build-out of a new pro shop.

“The project was complex,” says Andrew Sills, senior project manager, Hodges & Hicks General Contractors, Roswell, Ga. “The building is 100 years old, and many renovations had previously been done. We were continually discovering old infrastructure, which had to be redone. The actual construction was surgical, so to speak. But we provided a seamless tie-in to existing facilities, reinforcing existing historical structures, providing continuity of desired aesthetics, and meeting building code requirements.”

The club remained fully operational throughout all phases of construction with clear separation between members and ongoing construction activities, prioritizing safety and minimizing disruptions, according to Joshua W. Roland, AIA, LEED AP, CNU-A, principal, president, Chapman Coyle Chapman, Sandy Springs, Ga. “Phased construction plans accommodated special events and seasonal openings to accommodate members and ensure continuation of revenue streams.”

As with many design projects, communication among team members was essential. “There were a lot of opinions that had to be considered,” Sills says. “But everyone agreed that we shouldn’t spare expenses to bring in the best materials like millwork, steel trusses in the ballroom, flooring and tile.”

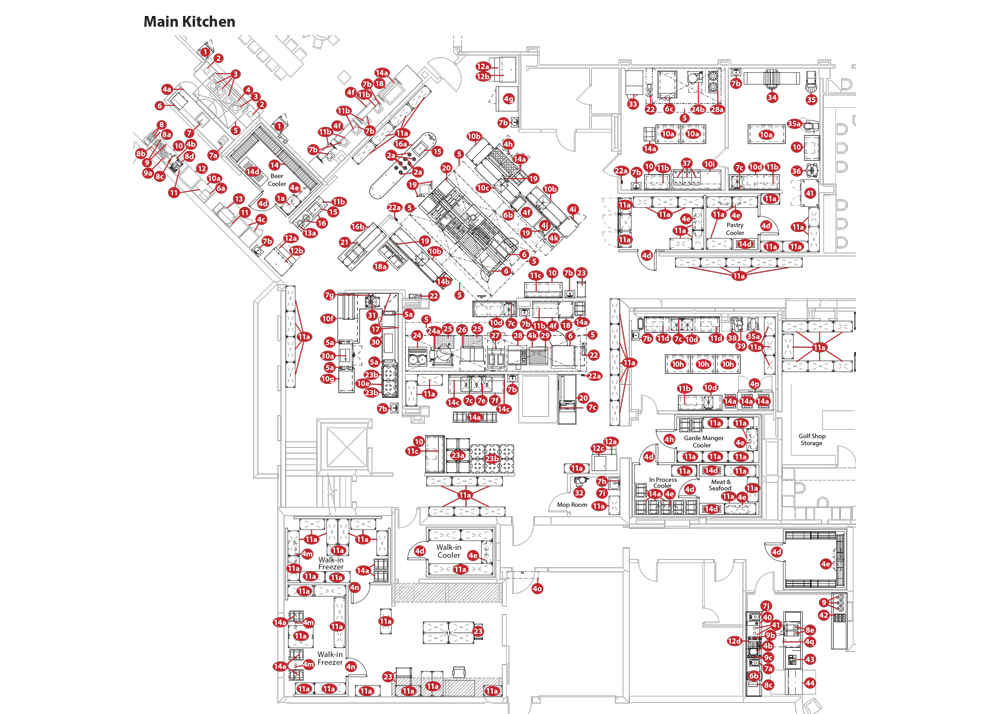

Floor Plan

Please click here to download the floor plan equipment key.

Renovation Challenges

This kitchen project focused on bridging several existing structures from previous additions while expanding its footprint to 10,000 square feet. “After demoing down to the original structure, plans were put in motion to rebuild a top-of-the-line gourmet kitchen that encompassed 10 freezers/refrigerators, a bakery section, a pastry service area, a new expo kitchen and an employee dining/break room area,” Roland says. Intentional upgrades led to required enhancements to the old infrastructure.

The columns covered in colorful tiles in the kitchen add a design element.“The old kitchen was 50 years old, and we had to increase firepower,” says Executive Chef Christophe Joignant, who has been at the club for nearly 25 years. “The renovation has helped us increase productivity and is very morale-boosting for the culinary team.”

The columns covered in colorful tiles in the kitchen add a design element.“The old kitchen was 50 years old, and we had to increase firepower,” says Executive Chef Christophe Joignant, who has been at the club for nearly 25 years. “The renovation has helped us increase productivity and is very morale-boosting for the culinary team.”

Yet completing the renovation presented daunting challenges. In 1995, areas of the main kitchen were renovated and expanded. This existing main kitchen, for example, was “disjointed and extremely inefficient,” according to foodservice consultant James C. Camacho, FCSI, CSI, president, Camacho Associates, Norcross, Ga. Camacho had designed the kitchen renovation in 1995. “Multiple Band-Aid attempts were made to improve the space over the years. But the staff was challenged to provide service to the members. As with many older facilities, the food and beverage staff do the best they can.”

“We planned well in advance by identifying as best we could every single pipe, ductwork, circuits, gas lines and grease lines,” Sills says. “Since the building is so old and renovations had been done previously, we had to do exploratory design and figure out what in the infrastructure had to be replaced.”

Architect Roland agrees. “When a building this old has renovations, things were added and changed. When we do renovation work, we don’t know what we’re going to find until we opened the ceiling and walls. Right in the moment, we would have to stop, look at what existed there and make on-site decisions about what to change.”

Throughout Phase 3, the Hodges & Hicks team went to work implementing new MEP systems, expanding grease hood ventilation and tying into an existing chilled water system.

For example, the original kitchen exhaust fan dated back to the 1930s. With the increase in cooking capacity needed to improve the quality of food and service, the exhaust needs increased. Great efforts were made to keep the existing fan and alter it to increase the revolutions per minute (rpm) and thus increase the cubic feet per minute (cfm). “But ultimately a new motor was needed to increase the fan speed,” Camacho says.

Soon after construction began, the team was advised that the main kitchen had to be functioning as soon as possible to keep foodservice going at all club venues supported by the main kitchen. “The design team needed to develop a plan that allowed the kitchen to be functional by providing ingress and egress points while appealing to the local code officials and fire marshal,” Camacho says. “A separate building permit for areas specific to the main kitchen was filed and granted approval.”

Staff use combis and fryers, as well as a charbroiler, a plancha, a skillet, and a tilting kettle to prepare menu items for most dining locations.

Staff use combis and fryers, as well as a charbroiler, a plancha, a skillet, and a tilting kettle to prepare menu items for most dining locations.

Main Kitchen and Bakery

Food arrives at a loading dock on the main level. Staff place menu ingredients in reconfigured areas that accommodate walk-in coolers, walk-in freezers and dry storage. “The cold storage space is great,” Joignant says. “It provides room for us to keep ingredients for many dining venues fresh.”

“We still have one of the issues, of course. A huge chase in the middle of the kitchen, built in the 1920s, holds the boilers, pipes, and everything coming up out of the boiler. It takes a chunk out of the middle of the kitchen, so we had to work around that one.”

Kitchen staff produce menu items for the family dining restaurant, which features casual American cuisine with a raw bar, chilled vichyssoise and other soups, salads, pasta and entrees ranging from jumbo lump crabcakes and filet mignon to chicken schnitzel. Handhelds such as French dip sandwiches, tacos and quesadillas also appeal to members of all ages. The kitchen staff also prepare menu items for catered events, as well as a few menu items for The Overlook.

The culinary team wanted a space dedicated for salad prep, vegetable prep and prep for ingredients for the main cooking sections. A new garde manger area holds a 30-quart mixer, a slicer and several prep tables and sinks. Staff take ingredients to the appropriate cooking stations and pass salads to the expediting station.

The bulk food production line contains double-stacked combi ovens, a charbroiler, a plancha range with conventional oven beneath, two fryers, a tilt skillet, a steam-jacketed kettle, two tilt kettles and a hot holding cabinet. “The kitchen has brigade cooking setup,” Camacho says. “The cooking starts at one end and works its way to the other end toward the expediter’s station.”

The cooking suite contains a mini combi, fryer, overhead cheese melter and an open six-burner range on each side of the rectangular suite. On one side sits a 48-inch charbroiler, a plancha grill and a deep fat fryer. The other side of the suite contains a French top and flat griddle.

“We also have a new blast chiller, which is so helpful to bring hot food temperatures down quickly,” Joignant says.

Members and their guests in the family dining restaurant can watch the culinary team at the cooking suite as they peer through a window that was installed during this renovation. “The vintage steel window, which was refurbished and fitted with new glass, was sourced out of Texas,” Roland says. “The areas within view received decorative wall tile around the cooking suite. This elevates the guest experience while creating more connectivity for the kitchen staff with club members.”

Culinary staff also appreciate another component of the renovation, a dedicated bakery/pastry and chocolate room. “The room allows staff to control humidity and temperature, because it is separate from the kitchen,” Camacho says. This area contains a reach-in freezer and a walk-in cooler, a stock pot range, a spiral mixer, a 30-quart mixer and a dough divider/rounder. Staff use a convection oven to bake specialty rolls, pastries and dough for some desserts such as cherry cobbler, warm chocolate chip cookie skillets and strawberry lemon shortcake. An area to cool baked goods was also built into this space.

An employee dining/break room also contributes significantly to staff members’ satisfaction. “The club takes care of the people who take care of the members,” Camacho says. “Employees have a nice place to go when they take a break.” New serving equipment and hot and cold wells help keep food quality high. Similar serving equipment, wells and induction warmers were also added to the women’s and men’s lounges.

The design team also paid attention to the way culinary staff circulate among stations and drop off dishes for cleaning. “We relocated the dish drop-off for a more direct drop-off by the servers,” Camacho says.

The dishwashing area contains clean and dirty dish tables, double-rack shelves, a sink with a disposer and an 86-inch conveyor dishwasher. “We also added a conveyor glass-washing machine,” Camacho says. “This way glasses aren’t touched by grease that builds up from a main dishwasher.”

A cooking suite supports menu item production.

A cooking suite supports menu item production.

Food and Beverage

The Refreshment Center, a new cafe, was added in an existing space. Located near the golf pro shop and member arrival, the space provides a convenient location for quick grab-and-go sandwiches, yogurt and salads displayed behind air screens, and beverages including water, coffee drinks including espresso and cappuccino, and teas. “Members also can sit at tables while visiting with friends or engaging in work,” Camacho says.

The renovated Overlook restaurant contributes to enhanced member satisfaction with a Mediterranean-inspired cuisine. “The former space, which was a display/finishing kitchen, could not keep up with demand,” Camacho says. “To fix this problem, designers had to expand the space to be a self-sufficient a la carte kitchen with more foodservice equipment to produce an expanded menu.”

The original The Overlook restaurant contained just enough cooking space for steaks, seafood, chicken, baked potatoes and vegetables, along with a salad bar. “The menu was very limited and had a tiny prep area in the back,” Camacho says.

The renovation expanded the cooking space to include a walk-in cooler near the cold prep area that includes a refrigerated sandwich prep rail for culinary staff to make salads and appetizers including charcuterie boards. A prosciutto slicer sits in one corner near ice cream cabinets. Staff use a conveyor toaster to warm bread that can stay warm in cabinets or be served immediately.

The hot prep area contains two 18-inch-wide fryers, two 6-burner step-up ranges, a 36-inch range-top plancha, a 48-inch charbroiler and an overhead salamander. Staff pass salads, sandwiches and hot menu items to an expediter station where a chef prepares plates for waiters to take out to customers. The expediter station contains pull-down lamps so culinary staff can hold at least eight to ten plates until servers pick them up for delivery to guests. Menu items include “social bites” such as shrimp al ajillo and baba ghanoush, as well as Greek salad and Moroccan tabbouleh salad. Entrees range from filet mignon and Atlantic halibut to chicken and mushroom pomodoro. Burgers and quesadillas also round out the menu.

At the opposite end of the prep area sits a small room with a conveyor dishwasher and three-compartment sink.

The existing Overlook bar was redesigned to provide not only the standard club cocktails but also the latest in bar trends. The bar contains an undercounter dishwasher, undercounter beverage tower and liquor display.

One of the more spectacular parts of the renovation is The Belvedere ballroom’s vertical expansion, which provides a larger space to host special events such as weddings and corporate parties to meet demand. The 5,300-square-foot expansion offers views of the swimming pool and golf course. Built as a vertical expansion above two existing stories, the ballroom required extensive planning, structural reinforcements and expert engineering. It features 23-foot-high ceilings, high-end finishes, decorative steel trusses, a mirrored full-service bar, an oversized stone fireplace, new restrooms and 14 sets of functional steel doors that open to multiple outdoor patios. The unique slate roof adds to the elegance and historic charm of the club.

Despite the challenges, the CCC Brookhaven renovation improved member satisfaction with dining and catering. It also contributed to staff satisfaction of working conditions. “The club is able to remain competitive while offering new amenities for members that appeal to all ages and continuing to provide the back-of-house configuration to support smooth operations,” Sills says. All of these directly impact the overall member satisfaction. These contribute as much as anything to the club’s ability to live up to its ‘Carpe Diem’ motto and continue to attract members for generations to come.

Camacho agrees, adding that “having been honored to design multiple food and beverage operations with Capital City Club from 1995 through 2025, this is one of the top 10 projects I have designed that brings me a great deal of pride. It is not just the design and layout of the kitchens — it is our relationship with the staff at the club and the entire design team. It took all to come together to design and build a great addition and renovation for the club and its members.”

The Belvedere’s 5,300-square-foot expansion contains 23-foot-high ceilings, decorative steel trusses, a mirrored bar and high-end finishes.

The Belvedere’s 5,300-square-foot expansion contains 23-foot-high ceilings, decorative steel trusses, a mirrored bar and high-end finishes.

About the Project

- Opened: March 2024

- Scope: Remodel and expansion of historic building to include primary kitchen and multiple dining areas

- Website: capitalcityclub.org

- Size: 55,340 sq. ft.

- Seats: The Overlook, 100; Women’s Lounge, 16; Women’s Terrace, 28; Men’s Lounge, 65; Men’s Terrace, 44; Belvedere, 150 for seated events and receptions

- Daily transactions/covers: Approximately 420 in areas with menu items prepared in the kitchen for the family dining room, The Overlook; covers for catering varies for each event

- Hours:

- The Overlook: 8 a.m. to 2:30 p.m.; 5:30 p.m. to 10 p.m.

- Refreshment Center: 7 a.m. to 5 p.m.

- Menu concepts: Kitchen prepares menu items for the family restaurant with casual American cuisine and some prep for the Mediterranean-inspired restaurant, The Overlook. The kitchen also supports catered events, banquets and to-go offerings.

- Staff: 257 total, including 30 in main kitchen

- Total project cost: $41 million

- Equipment investment: $2.86 million

The terrace off the Ladies’ Lounge provides a relaxing gathering spot.

The terrace off the Ladies’ Lounge provides a relaxing gathering spot.

Key Players

- Owner: Capital City Club

- Chief operating officer and general manager: Matt McKinney (retired February 2025); Eric Leland (current since March 1)

- Club manager: Michael Fick

- Director of engineering: Derek Frank

- Director of agronomy/project manager: Kyle Marshall

- Executive chef: Christophe Joignant

- Director of food and beverage: Jeffrey Mayer, CEC

- Executive sous chef: Raul Rodriguez

- Director of catering: Allison Schultz

- Catering manager, Brookhaven: Greta Vanderloop

- Architect of record: Chapman Coyle Chapman, Sandy Springs, Ga.: Joshua W. Roland, AIA, LEED AP, CNU-A, principal, president; Charlie Minton, project manager

- Interior design: Susan B. Bozeman Designs/Bozeman Club & Corporate division, Atlanta: Susan B. Bozeman, founder and principal

- Foodservice design: Camacho Associates, Norcross, Ga.: James C. Camacho, president, FCSI, CSI; Brett Daniel, FCSI, vice president; Nuong Nguyen-Chadwick, project manager

- General contractors: Hodges & Hicks General Contractors, Roswell, Ga.; Andrew Sills, senior project manager; Kerry Deese, project superintendent; Eric Henderson, project superintendent

- Mechanical/plumbing engineer: BAA Mechanical, Atlanta: Dave Goodson and Jeff Powell

- Structural engineer: PES Structural Engineers, Atlanta

- Electrical engineer: Conway & Owen, Alpharetta, Ga.: Ken Langley