How to make a dream come true? Edwin Bosso, Myrtle Consulting Group’s CEO, and his wife Edith wanted to open a restaurant and bar in Houston’s River Oaks Shopping Center, and they wanted it to equal the finest restaurants they had experienced while living in Paris.

Photos by Start ConceptsThe dream became a reality when the couple met chefs David Denis and Lionel Debon, and David’s brother, sommelier Sylvain Denis, all former partners of Houston’s Le Mistral.

Photos by Start ConceptsThe dream became a reality when the couple met chefs David Denis and Lionel Debon, and David’s brother, sommelier Sylvain Denis, all former partners of Houston’s Le Mistral.

The group of five formed a partnership to create Cocody Restaurant and Bar. The establishment is named after a suburb in Abidjan, Ivory Coast, Edwin Bosso’s birthplace. The restaurant’s name is also a nod to a reggae-infused song by the Ivorian band Alpha Blondy, “Cocody Rock,” which happens to be one of Bosso’s favorites.

“The Bossos encouraged the design team to draw inspiration from far-flung and unexpected sources around the world,” says Winn Wittman, AIA, NCARB, principal and founder, Winn Wittman Architecture, Houston. The architects and the interior designer, Nina Magon, founder and principal, Nina Magon Studio, Houston, incorporated features of the Art Deco era for which the shopping center was originally designed in the 1930s. Wittman also brought in Andre Medina, Los Angeles-based lighting designer; David Naggar, president, Preferred Foodservice Design/Supply Inc., Houston; and Consulting Engineering Services (CES) in the San Antonio office, to join the team.

“Every aspect of the interiors, from the selection of materials to the textures and furnishings, reflects a commitment to meticulous detail, sophistication, timelessness and elegance,” Wittman says.

The mural in the lounge artfully depicts the Mona Lisa savoring a lollipop, a delightful amalgamation of artistic humor and sophistication.

The mural in the lounge artfully depicts the Mona Lisa savoring a lollipop, a delightful amalgamation of artistic humor and sophistication.

The facility’s bar prominently features curved brass, Venetian plaster and backlit marble. Upon entering, Cocody guests gaze upon tonal pinks, mirrored champagne brass-colored arches, iridescent materials and a golden horseshoe-shaped bar. Many of these elements resemble those at one of the Bossos’ favorite Paris hotels, Hôtel Plaza Athénée. Many of the 5,000 individual lights are concealed within walls, stairs and wine racks, precisely programmed and coordinated to provide lighting that contributes to the restaurant’s overall ambience.

“Our aim was to create an ambience reminiscent of modern and stylish European restaurants, adorned with luxurious yet tasteful finishes,” Magon says. “We also wanted to create a setting that would serve as a worthy canvas for the exquisite and delectable cuisine offered.”

Magon describes the restaurant as a place where “a captivating interplay of refined elegance and playful whimsy takes center stage. A prime illustration of this juxtaposition is the remarkable mural in the lounge, where we’ve artfully depicted the Mona Lisa savoring a lollipop, a delightful amalgamation of artistic humor and sophistication. Other details include mesmerizing dichroic acrylic panels that grace the chef’s table and banquet room, the enchanting array of lighting fixtures, including the whimsical dancing chandelier and the majestic display of wines on multicolored LED acrylic shelves.”

The chef’s table private dining room is enveloped in a graceful arrangement of pink plastered panels and features a chandelier that evokes different moods depending on the cuisine being served.The design team encountered several challenges in bringing the Bossos’ vision to life. “Because of the unique characteristics of the project and the conditions of the site, these challenges ultimately became defining moments in our design,” Magon says. One such challenge was the presence of columns. Initially, the design team considered integrating them into the design by creating a tent-like atmosphere and transforming them into light fixtures. As the concept evolved, though, designers shifted their approach and made the columns standout features that seamlessly extend into the ceiling and booth seating, thereby creating a sense of anchorage within the space.

The chef’s table private dining room is enveloped in a graceful arrangement of pink plastered panels and features a chandelier that evokes different moods depending on the cuisine being served.The design team encountered several challenges in bringing the Bossos’ vision to life. “Because of the unique characteristics of the project and the conditions of the site, these challenges ultimately became defining moments in our design,” Magon says. One such challenge was the presence of columns. Initially, the design team considered integrating them into the design by creating a tent-like atmosphere and transforming them into light fixtures. As the concept evolved, though, designers shifted their approach and made the columns standout features that seamlessly extend into the ceiling and booth seating, thereby creating a sense of anchorage within the space.

“From the inception of Cocody, Lionel and I were involved in designing every facet of the dining experience,” David Denis says. Both Denis and Debon are involved in every activity from coordinating the kitchen to supervising the production process, including supervising the plating of each dish.

Taking sustainability into consideration, the team selected eco-friendly engineered wood flooring in the main dining area. “Given that the project was designed to accommodate high foot traffic, we sought a material that not only possessed aesthetic appeal but also demonstrated durability and resilience,” Magon says.

Facets of the dining experience include a French-inspired menu prepared in a culinary-laboratory-style kitchen with cooking suites so culinary staff can interact face-to-face across their stations. The all-electric equipment package includes such items as induction cooking hobs, fryers, planchas and combi ovens, as well as vacuum-packing equipment. “The owners selected all electric cooking equipment to maintain a comfortable working environment, for ease of cleaning and to minimize, if not eliminate, CO2 emissions,” Naggar says.

Chefs also insist that they don’t want their customers to experience an exclusively French menu. “We use French techniques — but the menu reflects a much wider global influence, and we use contemporary plating,” Denis says. He and Debon refer to French-born Paul Bocuse and Alain Ducasse, as well as American-born Charlie Trotter, among the respected chefs and restaurateurs who have inspired them during their careers.

“The chefs paid attention to every detail,” Wittman says.

Menu Production

When food deliveries arrive, the culinary team places menu ingredients in a walk-in cooler and dry storage. “We have a freezer but use it only for such items as our house-made ice cream,” says Debon. “Every menu ingredient we bring in is fresh. For instance, we fly in some ingredients from France, such as mushrooms and poultry, as well as live fresh red snapper from the Gulf of Mexico, lobsters from Maine and lamb from Colorado, beef from Illinois and foie gras from Hudson Valley.” The chefs also purchase locally grown microgreens and pork, beef and some fish varieties from Texas.

The main dining room features a composition of gold and pink with an array of polished metal elements that include mirrored champagne brass-colored arches.When preparing ingredients for cold and hot menu items for the restaurant and banquets in the prep area near the walk-in cooler, the culinary team uses a thermal blender, food processor, a cutter/mixer, a prep counter with a sink, a 20-quart mixer, a slicer and a batch ice cream machine. In this area, the team also cracks and steams the fresh Maine lobsters served whole and debones others for risotto and ravioli.

The main dining room features a composition of gold and pink with an array of polished metal elements that include mirrored champagne brass-colored arches.When preparing ingredients for cold and hot menu items for the restaurant and banquets in the prep area near the walk-in cooler, the culinary team uses a thermal blender, food processor, a cutter/mixer, a prep counter with a sink, a 20-quart mixer, a slicer and a batch ice cream machine. In this area, the team also cracks and steams the fresh Maine lobsters served whole and debones others for risotto and ravioli.

“We are laid-back chefs, but we are demanding,” Debon says. “We have a lot of high-tech equipment, but we have systems for preparation. We measure and weigh everything for each recipe so we have consistency.” Before the restaurant opened and now, new chefs had to train for four months before coming on board full-time so they understand the production systems and the taste of each menu item.

Due to limited dry storage space, kitchen designers mounted full-height stainless-steel wall cabinets with sliding doors around the perimeter of the kitchen, including in the areas where the two cooking suites reside. “As an extra measure for storage capacity, stainless-steel angles were secured to the underside of the wall cabinets,” Naggar says. “These angles were spaced to accommodate one-third-size hotel pans four inches deep.”

Early in the design team’s planning meetings, the chefs emphasized the kitchen must be easy to clean. “Therefore, full-height stainless-steel panels appear on all kitchen wall surfaces as well as stainless-steel on all the drop-ceiling panels,” Naggar says.

The horseshoe-shaped bar pays homage to the Hôtel Plaza Athénée in Paris. The translucent acrylic bottle rack stands above the bar, affectionately dubbed the “liquor chandelier.” It was custom crafted in Colorado and features rose-colored shelves illuminated from within while discreetly supporting more than 5,000 pounds of liquor bottles.In addition, the combi ovens are on casters, and all islands, cabinets, counters, the prep sink and pass station are either mounted on raised curbs or secured to the walls via cantilever brackets. Also, the backsplashes for all wall-abutting counters and cabinets are sealed to the stainless wall panels. “The heat-welded vinyl flooring was moved up four inches where it meets the concrete curb,” Naggar says.

The horseshoe-shaped bar pays homage to the Hôtel Plaza Athénée in Paris. The translucent acrylic bottle rack stands above the bar, affectionately dubbed the “liquor chandelier.” It was custom crafted in Colorado and features rose-colored shelves illuminated from within while discreetly supporting more than 5,000 pounds of liquor bottles.In addition, the combi ovens are on casters, and all islands, cabinets, counters, the prep sink and pass station are either mounted on raised curbs or secured to the walls via cantilever brackets. Also, the backsplashes for all wall-abutting counters and cabinets are sealed to the stainless wall panels. “The heat-welded vinyl flooring was moved up four inches where it meets the concrete curb,” Naggar says.

Early in the planning stages, the chefs insisted on padded flooring so the culinary team “can stand for hours in comfort,” Denis says.

Insulated flooring is only one consideration the executive chefs give to their team to support their efficient, consistent work and long-term health and well-being. “We spent a lot of money on ventilation to keep the temperature between 72 degrees F and 73 degrees F,” Denis says. “The dish machine is in a separate room so the steam doesn’t heat up the rest of the kitchen, and the hood system isn’t noisy. In addition, team members don’t work more than 8 hours, and they have at least two days off during the week.”

In addition to supporting an energy-efficient establishment, the chefs chose culinary cooking suites to encourage interaction among culinary team members as they prepare menu items. “In addition to dry storage cabinets, each station contains undercounter refrigerators so team members have their ‘own’ kitchens and don’t have to walk through other stations to get the ingredients they need,” Denis says.

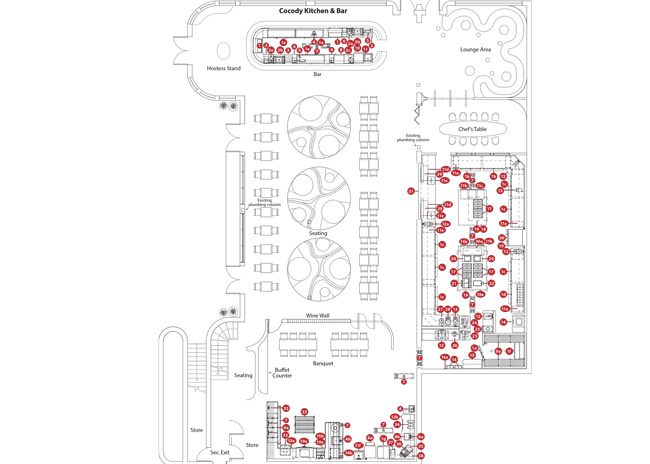

Floor Plan

Click here for the floor plan equipment key.

Cooking Suites and Production

At one cooking suite, culinary staff prepare cold appetizers and salads and desserts such as Anjou pear carpaccio, assorted berry elevated tart and Philadelphia vanilla cheesecake mille-feuille. The team also uses this area to prepare hot appetizers using induction cooking hobs and a rapid-speed oven.

The backsplashes for all wall-abutting counters and cabinets are sealed to the stainless wall panels.The other cooking suite contains induction cooking hobs on one side for sauteing vegetables and preparing sauces for fish and the other side for meat dishes. Risotto, foie gras and eggs are also prepared on the induction hobs. The team uses one induction plancha for marking and cooking salmon, red snapper and other fish and the other for marking and cooking meats such as ribeye steak. They finish some menu items such as fish in the electric combi oven and transfer them to hot holding cabinets. An overhead salamander, which was added after the original design, allows the team to finish and hold menu items at a hot temperature.

The backsplashes for all wall-abutting counters and cabinets are sealed to the stainless wall panels.The other cooking suite contains induction cooking hobs on one side for sauteing vegetables and preparing sauces for fish and the other side for meat dishes. Risotto, foie gras and eggs are also prepared on the induction hobs. The team uses one induction plancha for marking and cooking salmon, red snapper and other fish and the other for marking and cooking meats such as ribeye steak. They finish some menu items such as fish in the electric combi oven and transfer them to hot holding cabinets. An overhead salamander, which was added after the original design, allows the team to finish and hold menu items at a hot temperature.

Though the kitchen contains an electric fryer, Debon says it is only used to fry basil leaves and other garnishes. Instead, the team use the bain marie for custards, sauces and other dishes that demand precision and care.

Another cooking technique, vacuum packing, also supports the culinary team. “We aren’t cooking anything sous vide per se, but rather we use vacuum packing for the veal osso buco and our pork tournedo,” Denis says. After a menu item is placed in a vacuum-packed bag and sealed, it can then be heated in boiling water when needed. The team also uses this technique for smoked salmon, duck and pork.

No doubt the owners’ dream to create a unique fine-dining restaurant in Houston has come true. “Cocody is our gift to Houston and a place to write home about,” Bosso says. “When you step into Cocody you will immediately know you are in a special place. You will see the talent and feel the passion of all those involved.” As customers discover Cocody, they receive memorable impressions from the elegant and sophisticated interior design. They also get a taste not only of flavorful menu items but also of the culinary team’s activity in the all-electric kitchen.

The partners selected electric cooking equipment to maintain a comfortable working environment, for ease of cleaning and to minimize, if not eliminate, CO2 emissions.

The partners selected electric cooking equipment to maintain a comfortable working environment, for ease of cleaning and to minimize, if not eliminate, CO2 emissions.

About the Project

- Opened: Dec. 1, 2023

- Scope of project: Renovation of existing space to create a French-inspired fine-dining restaurant

- Website: cocodyrestaurant.com

- Size: 7,400 sq. ft.

- Back-of-the-house kitchen, including beverage and ware wash: 1,300 sq. ft.

- Dining room, 6,100 sq. ft.

- Seats: 200 and a 14-seat chef’s table

- Average check: $120

- Daily transactions/covers (average): 250

- Hours: 11 a.m. until 2 p.m., Tuesday to Thursday and Friday and Saturday; 6 p.m. to 10 p.m. Tuesday and Wednesday; 6 p.m. to 11 p.m. Thursday to Saturday; 11 a.m. to 3 p.m., Sunday. Bar hours: 11 a.m. to 10 p.m., Tuesday and Wednesday; 11 a.m. to 11 p.m., Thursday to Saturday; 11 a.m. to 3 p.m. Sunday.

- Menu concept and specialties: French-inspired cuisine

- Total staff: 90 working different times, including some full-time and some part-time

- Equipment investment: More than $600,000, including bar, kitchen and front of the house

Deep-fried basil leaves sit atop roasted Moulard duck breast accompanied by a velvety celery root puree and drizzled with Hudson Valley foie gras sauce.

Deep-fried basil leaves sit atop roasted Moulard duck breast accompanied by a velvety celery root puree and drizzled with Hudson Valley foie gras sauce.

Key Players

- Owners/investors: Edith Bosso and Edwin Bosso, CEO, Myrtle Consulting Group

- Executive chefs/operating partners: David Denis and Lionel Debon

- Sommelier/GM/operating partner: Sylvain Denis

- Executive sous chef: Patricio Del Pero

- Executive pastry chef: Marcos Sacalxot

- Assistant general manager: Lotfi Driouech

- Bar and restaurant manager: Eric Boyd

- Architect: Winn Wittman Architecture, Austin, Texas; Winn Wittman, AIA, NCARB, principal and founder

- Interior design: Nina Magon Studio, Houston; Nina Magon, founder and principal

- Lighting design: AM Light Studio, Long Beach, Calif.: Andre Medina, IES, assoc., AIA, principal and founder

- Kitchen design: David Denis and Lionel Debon, executive chefs and operating partners

- Foodservice design: Preferred Foodservice Design/Supply Inc., Houston: David Naggar, president, design and sales

- Equipment dealer: Preferred Foodservice Design/Supply Inc., Houston

- MEP Engineer: Consulting Engineering Services (CES), San Antonio office