Anthony’s Chophouse, Carmel, Ind.

Fine dining has arrived in the redeveloped downtown arts and design district in Carmel, Ind. Anthony and Kayla Lazzara opened Anthony’s Chophouse and, in the same building, 3UP Rooftop Bar, a first of its type in this upscale Indianapolis suburb.

The Lazzara name is well-known to community members. Anthony’s father, Chuck, owns and operates a renowned banquet and catering business called Ritz Charles; Anthony’s uncle, Matt Frey, owns Bub’s Burgers & Ice Cream across the street from Anthony’s Chophouse; and another uncle of Anthony’s, Joe Lazzara, owns Joe’s Butcher Shop, also located on the same street. Anthony has worked at all three locations, whetting his appetite for the hospitality business.

“I knew I wanted to go into the foodservice industry, and in high school I wrote a business plan for a fine-dining restaurant and rooftop bar,” Lazzara says. “I continually evolved the plan as I went through college with the idea of opening it after I graduated.”

Lazzara’s plan became reality in 2015. He and his father approached RATIO architects in Indianapolis to develop a 3-story, 14,000-square-foot restaurant building housing Anthony’s Chophouse, with seating and a bar on the main floor plus an iconic, refurbished bar on the mezzanine. The facility includes 3UP Rooftop Bar on the third floor, which also includes its own kitchen.

“The building faces out onto a public plaza with an interactive water feature that activates on the intersection of the Monon Trail [a popular bicycle and walking path] and Main Street,” says Joseph Yount, AIA, CDT, LEED AP, WELL AP, associate/architecture, at RATIO in Indianapolis. The firm served as the master planner, architect and landscape architect. The Chophouse building connects to a 4-story office building, 7 townhomes and a parking garage. “Our goal was to open all this in 14 months, but it took almost 17 months to complete the project,” Lazzara says.

Brick and stone masonry pilasters, along with a wood trellis, contribute to the masculine yet elegant space.

Brick and stone masonry pilasters, along with a wood trellis, contribute to the masculine yet elegant space.

The project’s most striking features include a two-story glazed wall with wood grain shading fins that looks out onto the public plaza and water feature, as well as a private patio set beneath an overhanging canopy. “The glass wall is set between brick and stone masonry pilasters, which also hosts a wood trellis that reaches out from the building into the plaza to provide a shaded area to host musicians performing for Jazz on the Monon, a free evening concert,” Yount says.

The third-floor rooftop bar offers views of the Monon Trail and a shaded outdoor patio area with two firepits and heaters to extend the outdoor serving seasons. “The owners’ vision was to create an icon of the community, a place in which generations would take pride,” says Loree O. Everette, president, PHANOMEN/design, an interior design and architecture firm in Indianapolis.

Grand African mahogany entry doors welcome guests and contain iron pulls featuring the restaurant’s signature “A” from the logo. “The space is decidedly masculine yet elegant with the balance of soft textures and fluid lines,” Everette says. She credits the firm’s lighting partner with the successful development of an intimate environment within the 25-foot-high ceilings and glass walls.

A towering floor-to-ceiling brick wall, embellished with an abstracted “A” painted overlay, holds a double-sided, 10-foot by 2-foot fireplace. “This gives the playful illusion of walking through fire as one ascends the stairs,” Everette says. The open kitchen appears as theater from the luxurious dining room. Guests can see staff preparing menu items for the steakhouse and rooftop bar.

Customers get a glimpse of the expo line and kitchen activity via the clean design presentation of that space.

Customers get a glimpse of the expo line and kitchen activity via the clean design presentation of that space.

The mezzanine level features Chophouse seating and a reassembled and restored mahogany bar, which was saved from demolition after the Glass Chimney restaurant containing it closed after 32 years in 2008. The main kitchen services the mezzanine with the help of a small server area in the back that supports the beverages, dishes and storage for this upper level. That creative extra came from foodservice designer Deven Kaufman, CFSP I, project manager, design and sales, at C&T Design and Equipment Co. in Indianapolis. Lazzara brought in C&T Design early in the design process to coordinate the kitchen equipment requirements with the architect, engineer and interior designer.

The mezzanine level features a reassembled and restored mahogany bar room, which was saved from demolition after the Glass Chimney restaurant containing it closed in 2008.

The mezzanine level features a reassembled and restored mahogany bar room, which was saved from demolition after the Glass Chimney restaurant containing it closed in 2008.

A marble mosaic tile floor trims the bar. “Throughout the space, porcelain and ceramic tile provide durability and exceptional beauty,” Everette says. “The selections allow the space to feel branded, yet authentic. This is especially true at 3UP, the crown of the structure.”

The rooftop patio features a large, 30-foot long by 12-foot tall living wall. The living wall and lounge seating surround two rooftop firepits that overlook the activity of the street. The 3UP Rooftop bar dining area also features large sliding windows which staff open during warmer months. “The lounge contrasts the restaurant below with bold blue accents enveloped within deep tones and a slightly industrial vibe. Inside, the glass bar top is a must-see and allows the bar to exude a chill sensuality,” Everette says.

The main level and third level bars feature a stainless steel modular bar die wall system with no legs to keep the space easy to maintain. The finished from panels are also removable for easy access to equipment when service needs arise.

The main level and third level bars feature a stainless steel modular bar die wall system with no legs to keep the space easy to maintain. The finished from panels are also removable for easy access to equipment when service needs arise.

Deliveries and Production

Food arrives at the back door of the restaurant, which each staff member can access with their own key. Staff place ingredients in ambient storage, a walk-in cooler for produce, a second walk-in cooler for meat and mise en place storage, and a walk-in freezer. “Products are inspected and properly placed on shelves using a first-in-first-out system,” Lazzara says. Staff bring the ingredients necessary for each shift to the prep areas and cooking line for the restaurant. Culinary staff also prepare ingredients for 3UP menu items, which they transport via an elevator to the third-floor kitchen’s storage areas on the cooking line.

The back-of-the-house preparation space contains equipment and sinks within easy reach of the front prep line.

The back-of-the-house preparation space contains equipment and sinks within easy reach of the front prep line.

Designers paid close attention to the efficiencies of the equipment package and the design of the spaces. “I designed the main kitchen around the relationships of the operational functions while keeping in mind the flow of the staff,” Kaufman says. This allows for an efficient layout that helps prevent mishaps while performing various tasks. The essentially circular layout features multiple entries and exits. The staff can drop off dishes, wash hands, prepare beverages and then run food from the expo line as necessary. Separate areas allow staff to trim meat and prepare salads and desserts.

As with most projects, the design team’s main challenge, says Kaufman, was ensuring all the walls, plumbing, electric and venting all properly matched the plans and were built as drawn.

“With the main kitchen being visible from the dining room, I made sure to provide a clean presentation of both the equipment and products ready to be served from the expo line,” Kaufman says. “We had most of the custom equipment fabricated out of stainless steel and utilized cooking equipment that could support a flexible menu without compromising the quality of the items being produced. The combination of the openings, windows and walls helped create a grand display.”

Culinary staff prepare ingredients for Chophouse menus.

Culinary staff prepare ingredients for Chophouse menus.

Staff at each station receive printed menu orders that slide along a rail. They prepare salads and desserts in a garde manger area. Moveable tables on rollers enable staff to easily transfer these menu items to a walk-in cooler for storage as necessary. In this area and throughout the kitchen, staff work on stainless steel counters and walk on slip-resistant flooring.

The hot cooking expo line features a stainless steel counter, warming windows, storage and heat wells. Staff use two convection ovens to bake crab cakes and short ribs, which cook for eight hours. They use a flattop for searing pork belly, salmon, rub-covered steaks and wagyu burgers. Refrigerated drawers beneath the flattop keep ingredients cold and easily accessible. Staff prepare steaks, pork and salmon in a 1,400 F-degree broiler. “Broiling steaks keeps the juices in the steaks versus losing the juices when using grills,” Lazzara says.

A finishing oven keeps menu items such as macaroni and cheese and scallops at proper temperatures and the salamander finishes menu items such as twice-baked mashed potatoes. These pieces of equipment also allow staff to slow down production as needed. Staff use the 16-burner range to saute side dishes and cook soups, and the fryers for frites and potato crisps. “We make fries and crisps from scratch,” Lazzara says. “We hand-cut the potatoes, which are soaked in water to eliminate the starch, par fried, quick chilled in a freezer and fried again, which gives the crispiness we’re looking for.”

Mobile equipment supports easy cleaning in the back-of-the-house space in the main kitchen.

Mobile equipment supports easy cleaning in the back-of-the-house space in the main kitchen.

Lazzara describes the menu as “an innovative take” on traditional steakhouse fare. “Our side dishes are not something you would typically see in a steakhouse,” he says. “We use the term vegcentric because we’re not just offering asparagus, baked potatoes with sour cream or other simple vegetables and starches on a plate. We also offer handmade gnocchi and sides such as roasted yams with savory spice, raisin and shallot chutney and walnut crumble.”

The expediter stands on the front side of the hot line to oversee the flow of proteins coming from the right side of the line, the appetizers from the middle and the sides from the left.

Guests see the staff moving in the kitchen through a glass wall that rises about four feet from the floor. “Guests feel part of the action by seeing staff from the waist up and they see flames from the equipment,” says Lazzara. “I wanted the restaurant to be chef-driven. But guests don’t need to see functions such as dishwashing, storage and waste removal.”

Open shelving enables staff members to see each other throughout the preparation space.

Open shelving enables staff members to see each other throughout the preparation space.

A bar on the main level and at 3UP on the third level feature a stainless steel modular bar die wall system with no legs. “This helps keep the space easily maintained and provides a clean look to guests,” Kaufman says. “The finished front panels are actually removable to allow the equipment to be easily serviced in the future as necessary.”

Another key feature on the main level is a machine that instantly chills and sanitizes glassware with liquid C02 that provides guests sitting at the bar a “show” effect. “We think this is the only one in Indiana,” Lazzara says. “We wanted to give the wow factor to guests and separate ourselves from other steakhouses.” Each floor also has unique beer/wine towers, one of which was custom made for the 3UP bar.

3UP Rooftop Bar and Kitchen

“The rooftop bar is a chef’s menu playground,” Lazzara says. “This is the first of its kind to our market. It lends itself to sharable, artistically designed menu items and handcrafted cocktails that drive indoor and outdoor dining.”

The third-floor cooking space contains fryers, a six-burner range, a flattop, a griddle, a conveyor oven and refrigeration.

The third-floor cooking space contains fryers, a six-burner range, a flattop, a griddle, a conveyor oven and refrigeration.

The kitchen’s linear and simple design enables staff to cook and assemble small, sharable plates requiring very little labor. Staff in the main kitchen prepare ingredients for 3UP and transport it via an elevator to 3UP kitchen’s storage on the cooking line. An upright refrigerator and freezer sit across from the cooking line.

The 3UP cooking line features two fryers for making fresh-cut potato crisps, hushpuppies, quail knots, fried desserts and other menu items requiring a quick fry. Staff use a six-burner range to heat prep ingredients and saute accoutrements for the menu items and a small flattop to cook sliders, meatballs, shrimp and shortribs. Staff use the griddle to finish sliders, toast buns and sear menu ingredients, along with a conveyor oven to bake menu items such as jalapeno poppers with cheese, flatbreads with green apple, figs, arugula, shallot caramel, whipped goat cheese, gastrique and herb oil, and toast points for other menu items. Desserts include cinnamon roll donut holes, tempura cookie dough and apple pie rangoons, all prepared in the 3UP kitchen. Expo windows contain built-in heat lamps.

The third-floor kitchen holds all the equipment necessary for storage and production throughout the service hours.

The third-floor kitchen holds all the equipment necessary for storage and production throughout the service hours.

Like the Chophouse bar, the 3UP bar contains multiple cocktail stations to provide more than one bartender with the equipment necessary to serve customers seated here, as well as in the dining areas, without crossing over one another. “I placed the dishwashing areas in the center, so that it could be shared between stations as necessary,” Kaufman says.

“We wanted to be conscious of the efficiencies of the equipment and the design of the spaces,” Lazzara says. “We wanted less steps for staff and to lessen the areas of cleaning by choosing and placing the equipment in the proper areas. All of the labor involved in a kitchen of this magnitude can be costly to a business. ”

With Anthony and Kayla’s new steakhouse restaurant and rooftop bar, the Lazzara family tradition grows and expands residents’ and visitors’ dining out experiences. They are proving that a longtime plan and dream can become reality with enough determination and vision to the future.

Facts of Note

- Opened: August 13,, 2018

- Scope of Project: Anthony’s Chophouse restaurant, kitchen and bar on the main floor, Chophouse seating and a restored bar from a local restaurant on the mezzanine, and 3UP rooftop bar and kitchen on the third floor

- Size: 14,000 sq. ft building; 4,185 sq ft. for back-of-the-house and bar equipment areas

- Seats: 410: 145 in Chophouse, plus 80 in the bar area; 60 on the mezzanine; and 125 in 3UP Rooftop Bar, which breaks down into 80 inside and 45 outside

- Average Check: $75 in Chophouse and $35 in 3UP

- Total Annual Sales: $4.5 million, estimated

- Daily Transactions/Covers: Average 150

- Hours: Anthony’s Chophouse: Lunch, 11 a.m. to 2 p.m., Monday – Friday, and dinner, 4:30 p.m. to 10 p.m., Monday – Saturday, and 4:30 p.m. to 9 p.m., Sunday. 3UP: 5 p.m. – 11 p.m., Wednesday —Saturday

- Menu Specialties: Center cut bone-in pork rack, pork belly, lobster bisque, hot fried chicken, soy braised short ribs, Wagyu Chophouse burger, Chesapeake Bay jumbo scallops, Faroe Island Scottish salmon; Flight of Beef (4 oz. prime, 7 oz. grass fed, 4 oz. wagyu); crab cakes; and 3UP short rib slammers

- Staff: 75 full time and part time

- Total Project Cost: $6.5 million

- Equipment Investment: $550,000

- Website: www.anthonyschophouse.com and www.3uprooftop.com

Key Players

- Owner: Lazzara Restaurant Group (LRG), dba Anthony’s Chophouse, and 3UP Rooftop Bar; Anthony and Kayla Lazzara

- Executive Chef: Justin Miller

- Architect: RATIO, Indianapolis: Joseph Yount, AIA, CDT, LEED AP, WELL AP, associate/architecture; John Jackson, project principal; Tom Cloud, project director; Brock Roseberry, project designer; Lisa Esterrich, landscape architect; Jeff Pitts, landscape architect

- Interior Design and Interior Architecture: PHANOMEN/design, Indianapolis; Loree O. Everette, NCIDQ certified, president and interior designer; Jeffrey Teuton, rockstar executionist; and Jeannie Marrugo, architect; Stephen Allen and Heather Bussell, interior designers with the firm at the time of this project

- Foodservice Design Consultants: C&T Design and Equipment Co., Indianapolis; Deven Kaufman, CFSP I, project manager, design and sales

- Equipment Dealer: C&T Design and Equipment Co., Indianapolis

- MEP Engineer: Genesis Engineering Group LLC, Zionsville, Ind.

- Construction Manager: Garmong Construction Services, Terre Haute, Ind.

Meet the Players

Loree O. Everette, president, PHANOMEN/design. Everette founded the firm in 2002 at the age of 27 and just after 9/11 when the hospitality industry was adjusting and reorganizing in response to the crisis. During the past 17 years, clients have included Vida, Provision and Livery in Indianapolis and Ruth’s Chris in downtown Indianapolis and Fort Wayne.

Deven Kaufman, CFSP I, project manager, design and sales, C&T Design and Equipment Co. Kaufman joined the company in April 2011. Previously he worked with architects and an HVAC, plumbing and electrical company and taught AutoCAD in high school and college.

Anthony Lazzara, owner, LRG Restaurants, dba Anthony’s Chophouse and 3UP. Before starting the restaurant and rooftop bar, Lazzara worked at his father’s banquet and catering business, Ritz Charles. He graduated from Ball State’s entrepreneurship program in 2013, using the steakhouse as his thesis.

Kayla Lazzara, owner, LRG Restaurants, dba Anthony’s Chophouse and 3UP. Working behind the scenes for LRG Restaurants, Lazzara serves as social media director and focuses on marketing. She began her career in the biomechanics field and also currently works as a clinical research specialist at the Indiana University Cancer Center.

Justin Miller, executive chef, Anthony’s Chophouse and 3UP. Miller joined Lazarra Restaurant Group in March 2018 after honing his skills as an executive chef in private country clubs in Indiana.

Joseph Yount, AIA, CDT, LEED AP, Well AP, associate/architecture, RATIO. Yount joined RATIO in 2005 and has worked on a wide range of projects since then, including the Eskenazi Health Ambulatory Care Building, Butler University’s Hinkle Fieldhouse renovation and Indiana State University’s Sycamore Dining Commons renovation.

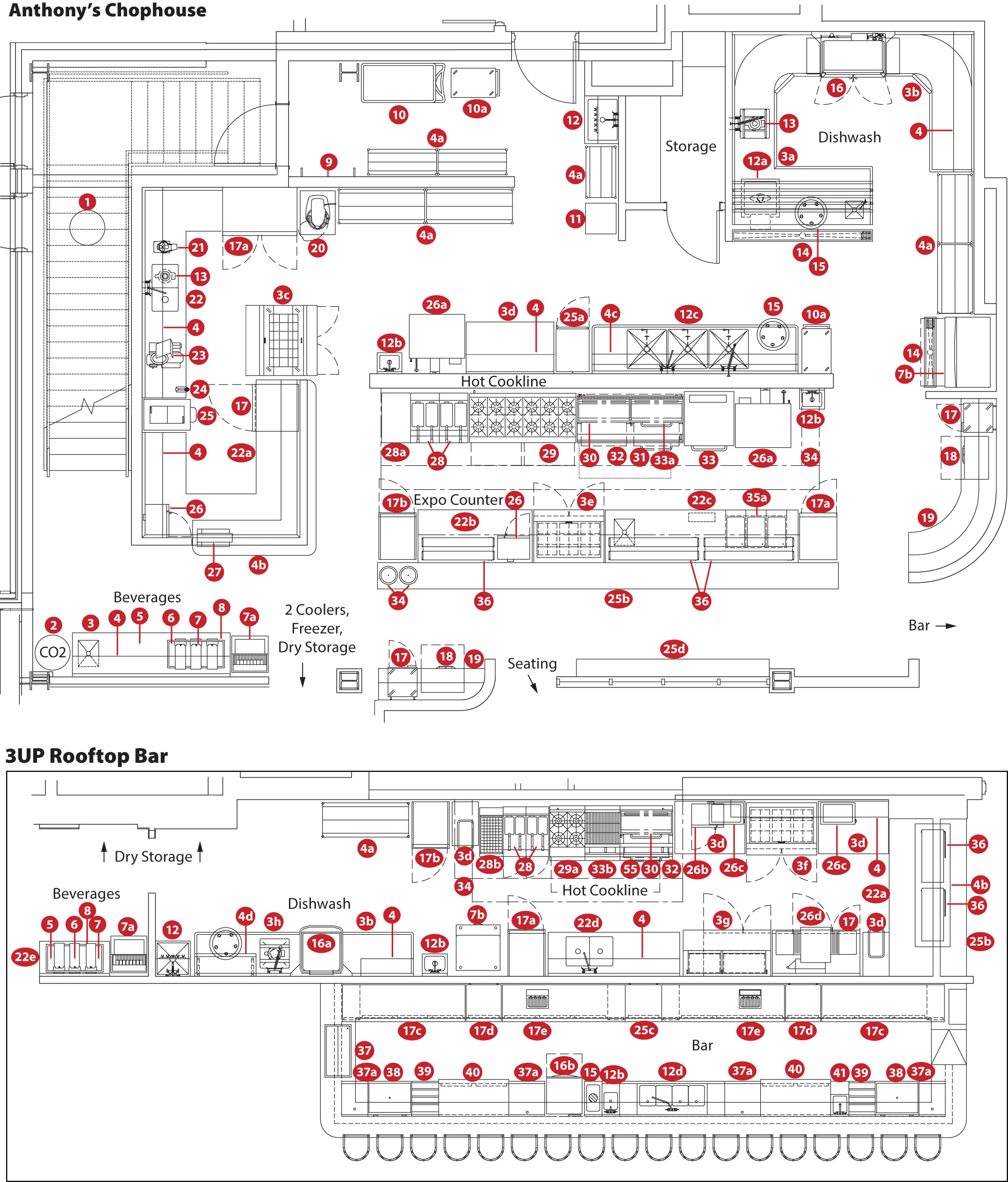

Equipment Key

1. Oil system

2. Bulk CO2

3. Beverage table w/sink

3a. Soiled dish table w/ dump and prerinse sinks

3b. Clean dish table

3c. Refrigerated salad prep table (double-sided)

3d. Worktable

3e. Refrigerated sandwich prep table

3f. Refrigerated salad/sandwich prep table

3g. Refrigerated pizza prep table

3h. Soiled dish table w/disposer

4. Wall shelf

4a. Wire shelving

4b. Pass-thru shelf

4c. Wall shelf w/pot rack

4d. Slanted dishrack shelf

5. Coffee brewer and accessories

6. Tea brewer and accessories

7. Water dispenser

7a. Soda dispenser and ice bin

7b. Ice machine, bin and water filter

8. Bagged soda rack

9. Coat hooks

10. Waste cart

10a. Utility cart

11. Soiled linen basket

12. Mop sink and accessories

12a. Utensil soak sink

12b. Hand sink

12c. Three-compartment sink

12d. Four-compartment sink

13. Disposer

14. Floor trough

15. Waste container

16. Conveyor dish machine

16a. Dish machine

17. Undercounter refrigerator

17a. Reach-in refrigerator

17b. Reach-in freezer

17c. Backbar bottle cooler (three glass doors)

17d. Backbar wine cooler (glass door)

17e. Backbar beer cooler and dispenser

18. Warming drawer (double)

19. Server station

20. 20-qt. mixer w/mobile stand

21. Food processor

22. Prep counter w/sinks

22a. Work counter

22b. Expo counter

22c. Chef’s counter w/sink

22d. Work counter w/sinks

22e. Beverage counter

23. Slicer

24. Can opener

25. Ice cream cabinet w/dipper well

25a. Holding cabinet

25b. Plate cabinet

25c. Backbar storage cabinet

25d. Utensil/condiment cabinet

26. Microwave oven

26a. Double convection oven

26b. Microwave oven w/shelf

26c. Food warmer

26d. Ventless conveyor oven

27. Hot food holder

28. Fryer

28a. Dump station w/heat lamp

28b. Dump station

29. 12-burner range w/ovens

29a. Four-burner range

30. Cheese melter

31. Griddle

32. Refrigerated equipment stand

33. Broiler

33a. Salamander

33b. Charbroiler

34. Exhaust hood

35. Countertop soup holder

35a. Three-pan drop-in hot well unit

36. Heat lamp

37. Bartop drain board

37a. Underbar drain board w/glass storage

38. Underbar ice bin w/soda gun

39. Underbar bottle display

40. Mug froster

41. Underbar blender station