High-quality, freshly prepared food sets a new standard at this waterpark.

Keith Dalton, RayDeLaughter and Terry Hlavinka grew up in the Houston area. The three friends all attended Texas A&M together. Years later, after each had built his own successful business, they joined forces to create a venture that would give something back to their childhood neighborhoods. "Our first goal was to add value to the community by offering people a place to play and have fun," says Hlavinka.

Keith Dalton, RayDeLaughter and Terry Hlavinka grew up in the Houston area. The three friends all attended Texas A&M together. Years later, after each had built his own successful business, they joined forces to create a venture that would give something back to their childhood neighborhoods. "Our first goal was to add value to the community by offering people a place to play and have fun," says Hlavinka.

The venture: launching an enormous $45 million waterpark called Typhoon Texas next to the Katy Mills outlet mall in Katy, Texas, a Houston suburb. "This waterpark, which sits on 25 acres, is the largest waterpark built by a private investment group in the past 10 years," says Evan Barnett, general manager.

The owners' heritage rings true throughout the park, perhaps most obviously with the enormous Texas flag that appears on the wall of the Texas Twister raft ride. The park compels guests of all ages to participate in more than 13 rides and attractions, including Tidal Wave Bay, a 27,000-square-foot wave pool, as well as The Typhoon, a 48-foot interactive children's structure, plus a 1,345-foot lazy river. The Slide Boarding attraction combines video gaming and water slide experiences.

"The Typhoon Texas theme is Texas Hill Country or just Texana [in reference to the history and culture of Texas]," says Terry Brannon, president, C.T. Brannon Corp., the architectural firm for Typhoon Texas. "The idea was to create more of a batten board finish and not so much masonry with corrugated metal roof, like you find in the Texas Hill Country. Exposed wooden beams add to the theme."

Specifying the Food

The River Grill contains seven windows offering burgers, hot dogs, grilled salmon and french fries.One of the challenges facing the owners and architects was deciding how much foodservice to incorporate. They anticipated the park would have a daily attendance of 3,000 to 4,500 people and might even crest at 8,000 people a day. "We had plenty of room, so space was not so much an issue as what to place in which area," Brannon says. The answer was to construct a large central cafeteria/commissary building with a screened dining room overlooking the lazy river and outdoor dining. The commissary staff produces menu items for the park's River Grill, Smokin' BBQ and Taqueria concepts.

The River Grill contains seven windows offering burgers, hot dogs, grilled salmon and french fries.One of the challenges facing the owners and architects was deciding how much foodservice to incorporate. They anticipated the park would have a daily attendance of 3,000 to 4,500 people and might even crest at 8,000 people a day. "We had plenty of room, so space was not so much an issue as what to place in which area," Brannon says. The answer was to construct a large central cafeteria/commissary building with a screened dining room overlooking the lazy river and outdoor dining. The commissary staff produces menu items for the park's River Grill, Smokin' BBQ and Taqueria concepts.

Team members also produce food and deliver it to foodservice units called Ray's Pizza and Italian Icehouse, plus catered events at The Birthday Barn.

"People don't like to wait long for their food, but on the other hand you cannot have unused capacity either," Brannon says. "Using multiple smaller service windows instead of one large counter, we were able to close off windows during nonpeak times and still staff up to meet demand."

Texas Treats features funnel cakes, ice cream, sweets and beverages.Whether to air condition the kitchens presented another challenge. "The commissary is a hot place to work and with the windows open all the time a lot of electricity is eaten up trying to cool a building down with so many ovens and fryers," Brannon says. "We took the barbecue smoker out of the main kitchen, enlarged it and put it in its own room. We brought in fresh air circulation in the ceiling and with the exhaust hoods we are pulling in outdoor air. It still is quite warm but not nearly as hot as outdoors."

Texas Treats features funnel cakes, ice cream, sweets and beverages.Whether to air condition the kitchens presented another challenge. "The commissary is a hot place to work and with the windows open all the time a lot of electricity is eaten up trying to cool a building down with so many ovens and fryers," Brannon says. "We took the barbecue smoker out of the main kitchen, enlarged it and put it in its own room. We brought in fresh air circulation in the ceiling and with the exhaust hoods we are pulling in outdoor air. It still is quite warm but not nearly as hot as outdoors."

Smokin' BBQ consists of a screened-in room with no glass. The screen works to keep insects out. The River Grill setup also includes a screened-in room with gas grills inside.

In keeping with the casual atmosphere of the amusement park, the commissary, service windows and seating feature stainless steel tables and counters. The site features wood stud walls with exterior cement board siding, interior fiberglass reinforced panel walls in the kitchen, sealed concrete floors and reflective plywood roofing to keep down the exterior radiant heat load. Supply air ducts and fans keep the hoods from pulling hard on the service windows.

"We didn't want the food to get sucked back into the kitchen once served," Brannon says. "Ceilings are lay-in fiberglass reinforced panel squares for ease of cleaning."

The smaller foodservice areas are prefabricated and skid-mounted so that they can be moved. Others are stick-built and fixed at their present location. "We used essentially the same detailing everywhere so that the construction work was not delayed," Brannon says.

A special rub coats the brisket."For foodservice, the owners wanted to do something different that no other group had tried," Barnett says. "What comes to mind when you think of foodservice at a big waterpark? Certainly not great, good-tasting, freshly made food. The owners decided to change the model and introduce high-quality food to this venue."

A special rub coats the brisket."For foodservice, the owners wanted to do something different that no other group had tried," Barnett says. "What comes to mind when you think of foodservice at a big waterpark? Certainly not great, good-tasting, freshly made food. The owners decided to change the model and introduce high-quality food to this venue."

A team of foodservice consultants from Profitable Food Facilities, based in Poway, Calif., came on board to bring the foodservice vision to reality. That team included: Mike Holtzman, president; Scott Steele, project manager; Jessica Glidewell, lead consultant; and Mike Borassi, chef consultant. Together they designed unique foodservice spaces and developed freshly prepared menus for each operation.

"We asked the owners if they wanted to be like most other parks serving average food at a high price," Holtzman says. "We explained that the food can actually enhance the guest experience, but it can also add to the list of reasons guests don't want to come back. If there are large numbers, the slide lines get long. So if the lines are long and the food is bad, and it's a hot weather day and they paid $44 a person to get in, why would they come back? But if the food is really good quality and the systems we have in place move the lines, then this becomes a positive and will impact guests' decision to return."

Agreeing that the food should be rated at least 8 out of 10, the project team decided to set the food apart from other amusement parks by using fresh ingredients, including hamburger patties, chicken and salmon. The team also purchases menu items such as all-beef hot dogs and opts to hand-bread chicken tenders daily.

Nachos rank as a favorite menu item among visitors."Our challenge was to design a foodservice system that will allow the park's staff to serve up to 8,000 waterpark guests on one day," says Holtzman. "These numbers might include banquet groups of up to 1,000 people and people taking advantage of the 40 cabanas who, of course, want lunch at the same time as the lunch-rush group."

Nachos rank as a favorite menu item among visitors."Our challenge was to design a foodservice system that will allow the park's staff to serve up to 8,000 waterpark guests on one day," says Holtzman. "These numbers might include banquet groups of up to 1,000 people and people taking advantage of the 40 cabanas who, of course, want lunch at the same time as the lunch-rush group."

Using menu data from each foodservice outlet allows the staff to be ready for any rush. Equipment placement and counter service with windows where guests place orders allow staff to fill each order in less than a minute. "Service start times are staggered beginning at 10:30 a.m.," Holtzman says. "The staff moves hundreds of guests through continuously and is ready for the majority of guests from 12 p.m. until 2 p.m."

Kitchen Production and Service

The central kitchen supports food preparation for all daily operations. Because of the kitchen's location, all deliveries must occur before the park opens. Deliveries arrive at the loading dock, where staff take food to the walk-in coolers designated for meat, produce and poultry, all located within 25 feet of the entry. Dry storage also sits very close to the entry. "The three major walk-ins are walk-throughs, so the food is simply moved forward to create a first in, first out inventory system and product does not have to rotate," Holtzman says.

Staff completes menu preparation for The River Grill in a room adjacent to the walk-ins. They place finished products into a walk-in cooler or take them straight to the service line. Staff also prepare menu items for other outlets here and place these items into a fourth walk-in to remain chilled until they are distributed to the other outlets. Each outlet manager fills out a requisition sheet the night before service so prepared menu items can be distributed to each kiosk or small kitchen by 10 a.m. The prep room sits adjacent to the dishwashing area in order to minimize the steps from one area to the other. The service entrance for collecting trays sits next to the dishwashing station as well.

Staff members hand bread the chicken tenders.The prep room features tables, slicers and a food processor. A fryer system with automatic filtration allows staff to produce up to 70 cases of french fries and 100 pounds of breaded chicken tenders daily. Pass-thru warmers sit next to the fryers, allowing staff to produce fried products in the back and pass cooked menu items to teammates in the front. Staff use the 10-burner range to prepare 50 pounds of barbecue beans and 60 quarts of barbecue sauce up to twice a day for Smokin' BBQ. The range also heats and holds menu items for catered events.

Staff members hand bread the chicken tenders.The prep room features tables, slicers and a food processor. A fryer system with automatic filtration allows staff to produce up to 70 cases of french fries and 100 pounds of breaded chicken tenders daily. Pass-thru warmers sit next to the fryers, allowing staff to produce fried products in the back and pass cooked menu items to teammates in the front. Staff use the 10-burner range to prepare 50 pounds of barbecue beans and 60 quarts of barbecue sauce up to twice a day for Smokin' BBQ. The range also heats and holds menu items for catered events.

"The operation spent more than $75,000 in custom-made wood-burning smokers to produce up to 100 6-pound briskets, 30 pork butts, 40 chickens and and 100 half-pound smoked sausage links to keep up with daily volume," Holtzman says.

Char grills sit outside The River Grill.Perhaps the most unique piece to the operation is the Fresh Grill Shack, located 30 feet from The River Grill's seven windows. When guests order a hamburger, chicken or salmon at the windows, staff give them a bun, lettuce and tomato. Guests carry their trays to the Fresh Grill Shack and staff place their fresh-grilled hamburger, chicken or piece of salmon on the bun. Staff know which protein to put on the buns because customers ordering a hamburger get a white bun, chicken goes with a wheat bun and the salmon has a white bun with a lemon wedge on the side of the plate. Staff continuously grill proteins to keep pace with demand.

Char grills sit outside The River Grill.Perhaps the most unique piece to the operation is the Fresh Grill Shack, located 30 feet from The River Grill's seven windows. When guests order a hamburger, chicken or salmon at the windows, staff give them a bun, lettuce and tomato. Guests carry their trays to the Fresh Grill Shack and staff place their fresh-grilled hamburger, chicken or piece of salmon on the bun. Staff know which protein to put on the buns because customers ordering a hamburger get a white bun, chicken goes with a wheat bun and the salmon has a white bun with a lemon wedge on the side of the plate. Staff continuously grill proteins to keep pace with demand.

"By monitoring hourly sales of proteins, staff know the proper amount of proteins to cook each hour so they can keep up with guests' needs without running out. The food can't be any fresher than this," Holtzman says. "We located the grill shack away from the main service line to give our cooks a little extra time to serve the guests and to locate it near the main walkway of the waterpark to remind the guests there is fresh food ahead."

Speed and Sustainability

Just as critical as speed of service for production is speed of service at the counters. "Counter service can be slow because each guest has to make choices and all of these choices take time to communicate, like 'All combos come with chips — would you like to upgrade to fries?' 'Would you like to upgrade to a fry bucket?' 'What size drink?' 'What type of drink?' All those questions take time to answer. We took that out of the equation with our 'line busters,' who take orders in line when we have more than 10 customers in line," Holtzman says. "We determined that this took the line speed from two minutes per guest down to as fast as one minute per guest. So this doubled the line speed! Adding one or two line busters

was an easy investment to increase sales and profits significantly."

After evaluating several different approaches, adding condiments continued to negatively impact speed of service. "Individual disposable condiment packs were too messy and a box system we had purchased didn't work," says Holtzman. "But when you are going through up to 25 gallons of ketchup a day, this becomes a real issue."

Now, staff place condiments such as pickles on burgers at different points of service. Guests add their own ketchup, mustard and mayonnaise from dispensers. "In order to maximize efficiency, we have to have up to three staff members refilling condiments from 11 a.m. until 4 p.m. daily," Holtzman says.

Guests pick up beverages and refills at the service windows. Double-stacked ice machines set on an elevated ice system produce 6,000 pounds of ice daily, which staff then easily transport throughout the park.

The small foodservice units each contain a single on-door cooler, a freezer and prep tables. At Ray's Pizza, a double-stacked quick-speed, ventless oven bakes pies that staff dress with cheese and sauce. "Using these ovens allowed us to avoid using a hood," Holtzman says. The Taqueria uses a simple three-foot flat grill with a small hood to produce up to $6,000 in sales daily.

Attending to sustainable practices shows clearly in the food selection. "We use fresh hamburger meat," Holtzman says. "We don't use chicken breast that is smashed and formed to create consistency, and we don't use chicken nuggets that are 40 percent meat and 60 percent bone and other fillers. We, as operators, have a responsibility to serve wholesome food. It is not that hard."

Growing Pains, the Payoff and the Future

The three major walk-ins are walk-throughs. The food is simply moved forward to create a first-in, first-out inventory system and product does not have to rotate."We only received the certificate of occupancy on the building one day before we opened, so we had one day to train our staff for one of the busiest weekends of the year," Holtzman says. "Even by July 1, the average employee had worked maybe 15 to 20 shifts. However, we saw a dramatic increase in per cap [average spend per guest] from $4.66 in June to some days as high as $8.77 per guest. This had a lot to do with just getting used to the operation and muscle memory of their steps."

The three major walk-ins are walk-throughs. The food is simply moved forward to create a first-in, first-out inventory system and product does not have to rotate."We only received the certificate of occupancy on the building one day before we opened, so we had one day to train our staff for one of the busiest weekends of the year," Holtzman says. "Even by July 1, the average employee had worked maybe 15 to 20 shifts. However, we saw a dramatic increase in per cap [average spend per guest] from $4.66 in June to some days as high as $8.77 per guest. This had a lot to do with just getting used to the operation and muscle memory of their steps."

Barnett reports that feedback from the park guests on quality was positive. "We hit our bottom-line goals because, with our background in operations, we were able to set up the food specifications and pricing to ensure we met our food-cost goals. With 5,000 or more in the park, the payroll was under 20 percent."

"The bottom line is we have now built and operated a waterpark that can serve fresh product efficiently to its guests and that will enhance the overall experience of the waterpark for the guests," Holtzman says. "Knowing that no other park has even tried this shows that now we can set a new standard. We also can do it with a food and labor cost under 50 percent. So everyone wins. The guests win, the owners win."

To put the financials into context: Food is the second-largest producer of revenue in the park. The waterpark opens over Memorial Day weekend, remains open for 100 days, then closes due to weather. However, Typhoon Texas hosts a Christmas event called WinterFest during the holiday season.

Offering unique experiences to encourage guests to return again and again, the park features Splash Cinema, a Thursday evening movie night, and weekly summer camps offering kids games, arts and crafts and ecological experiments. The park will likely add more rides in the future and may even add lodging on the additional 20 acres of undeveloped land. Of course, the standard of food quality has already been elevated, so new additions to the menu must measure up to expectations. That's a tall order, but one the park's owners and employees seem ready to fulfill.

Facts of Note

- Opened: May 30, 2016

- Scope of Project: New, private waterpark, funded by a private investment group owned by Keith Dalton, Ray DeLaughter and Terry Hlavinka. The 25-acre park includes 4 slide towers and 27 slides. A main commissary provides food for The River Grill (7 windows), Smokin’ BBQ (4 windows) and Taqueria (2 windows), and supports Ray’s Pizza (3 windows), Italian Icehouse and catered events at The Birthday Barn. Typhoon Texas also features Rainbows of Ice (2 windows) with shaved ice and cotton candy; Texas Treats (2 windows) with funnel cakes, smoothies, shakes, soda floats, soft serve ice cream and cotton candy; and 2 Mini Melts carts.

- Attractions: The Lazy-T, a lazy river running the length of 3 football fields; Tidal Wave Bay, a 1-million-gallon wave pool; The Snake Pit with The Rattler, The Copperhead, The Water Moccasin, The Diamondback and slide boarding; Buckaroo Bayou for toddlers; the Gully Washer with 4 stories of spray areas, slides, elevated walkways and rope bridges; Monster Storms, including The Texas Twister and The Typhoon; Howdy Hollow; The Duelin’ Daltons with The Gunslinger, The Bullchute, The Shootout, The Bronc Buster and The Mutton Buster; and Lone Star Racers.

- Size: Main kitchen, 5,000 sq. ft., with service area supporting all foodservice operations. The River Grill, 2,000 sq. ft.; Smokin’ BBQ, 1,500 sq. ft.; Taqueria, 200 sq. ft.; Ray’s Pizza, 600 sq. ft.; Italian Icehouse, 200 sq. ft.; Rainbows of Ice, 100 sq. ft.; Sweet Tooth, 200 sq. ft.; and Mini Melts, 100 sq. ft.

- Seats: 1,500 seats for all service windows. Three picnic pavilions seat 400 each for catered events of up to 1,200 people or more.

- Average Check: $6.25 to $7

- Total Projected Annual Sales: $3 million

- Daily Transactions/Covers: Up to 8,000 people per day with up to 11,000 transactions a day.

- Hours: Open Memorial Day to Labor Day, 10 a.m. to 7 p.m., Sunday through Thursday; 10 a.m. to 10 p.m. Friday and Saturday. WinterFest Christmas Festivities, Nov. 25 until Dec. 31, from 6 p.m. until 11 p.m., weekdays; Friday, Saturday and Sunday, 6 p.m. until midnight.

- Menu Specialties: At River Grill, fresh grilled-to-order burgers, grilled teriyaki chicken, grilled salmon and grilled hot dogs. Chicken tenders are all fresh-battered (never frozen); grilled chicken wrap; Grill Box (citrus grilled chicken on a spinach tortilla with romaine lettuce, tomatoes, red onion, cheddar cheese and ranch dressing); french fries, nachos, smoothies, churros and soft pretzels. At Smokin’ BBQ, custom-made smokers produce fresh, in-house smoked menu items including Angus brisket, sausage, pulled pork, half chicken and combo meat plates; sides of potato salad, house-made coleslaw and house-made barbecue beans. At Taqueria, carne asada beef tacos, chicken tacos, combination tacos, regular nachos, Texas nachos, churros, soft pretzels and frozen lemonade. At Ray’s Pizza and Italian Icehouse, fresh-made pizza, gluten-free pizza, fresh salads, fresh-baked cookies, brownies and Italian ice.

- Staff: 260 food and beverage employees (seasonal, part-time), 10 leads (a team member in charge of one or two groups of employees), 2 managers and 1 pit master in charge of cooking food on the smokers

- Total Project Cost: Approximately $49 million

- Foodservice Equipment Investment: $495,000

- Website: www.typhoontexas.com

Key Players

- Owners: Keith Dalton, Ray DeLaughter and Terry Hlavinka

- General Manager: Evan Barnett

- Architect: C.T. Brannon Corp., Tyler, Texas; Terry Brannon, president

- Foodservice Consultants: Profitable Food Facilities, Poway, Calif.; Mike Holtzman, president; Scott Steele, project manager; Jessica Glidewell, lead consultant; and Mike Borassi, chef consultant

- Equipment Dealer: Mission Restaurant Supply, Dallas/Ft. Worth

- Construction: KDW Ltd., Houston

Meet the Players

Keith Dalton, part-owner, Typhoon Texas Waterpark. Dalton is president/CEO of KDW, which offers unique design-build solutions for industrial and manufacturing clients. He also has experience with successful developments in the Houston area.

Keith Dalton, part-owner, Typhoon Texas Waterpark. Dalton is president/CEO of KDW, which offers unique design-build solutions for industrial and manufacturing clients. He also has experience with successful developments in the Houston area.

Terry Hlavinka, part-owner, Typhoon Texas Waterpark. Hlavinka operates Hlavinka Equipment Company, which is engaged in the construction, agricultural and automotive industries. Hlavinka has experience with successful developments in the Houston area.

Terry Hlavinka, part-owner, Typhoon Texas Waterpark. Hlavinka operates Hlavinka Equipment Company, which is engaged in the construction, agricultural and automotive industries. Hlavinka has experience with successful developments in the Houston area.

Ray DeLaughter, part-owner, Typhoon Texas Waterpark. DeLaughter is the CFO of VantageCFO, a financial consulting firm that provides CFO services to growing companies.

Ray DeLaughter, part-owner, Typhoon Texas Waterpark. DeLaughter is the CFO of VantageCFO, a financial consulting firm that provides CFO services to growing companies.

E van Barnett, general manager, Typhoon Texas Waterpark. Barnett has helped develop and operate multiple waterparks during his 20 years of experience. He has also consulted with several waterpark and family entertainment centers as a risk consultant.

van Barnett, general manager, Typhoon Texas Waterpark. Barnett has helped develop and operate multiple waterparks during his 20 years of experience. He has also consulted with several waterpark and family entertainment centers as a risk consultant.

Calvin Terrell Brannon, P.E., president/founder, C.T. Brannon Corp. Brannon worked for the Department of Public Works before forming his own company. He is responsible for the firm's civil engineering division, designing water, sewer, paving and drainage for public and private entities. He is also responsible for project design and construction-phase engineering for all types of aquatic facilities.

Calvin Terrell Brannon, P.E., president/founder, C.T. Brannon Corp. Brannon worked for the Department of Public Works before forming his own company. He is responsible for the firm's civil engineering division, designing water, sewer, paving and drainage for public and private entities. He is also responsible for project design and construction-phase engineering for all types of aquatic facilities.

Michael Holtzman, president of Profitable Food Facilities. Holtzman has more than 37 years of restaurant industry experience. His company specializes in designing kitchens and operational consulting for captive market restaurant locations including hotels, golf resorts, private country clubs, theme parks, ski resorts and waterparks.

Michael Holtzman, president of Profitable Food Facilities. Holtzman has more than 37 years of restaurant industry experience. His company specializes in designing kitchens and operational consulting for captive market restaurant locations including hotels, golf resorts, private country clubs, theme parks, ski resorts and waterparks.

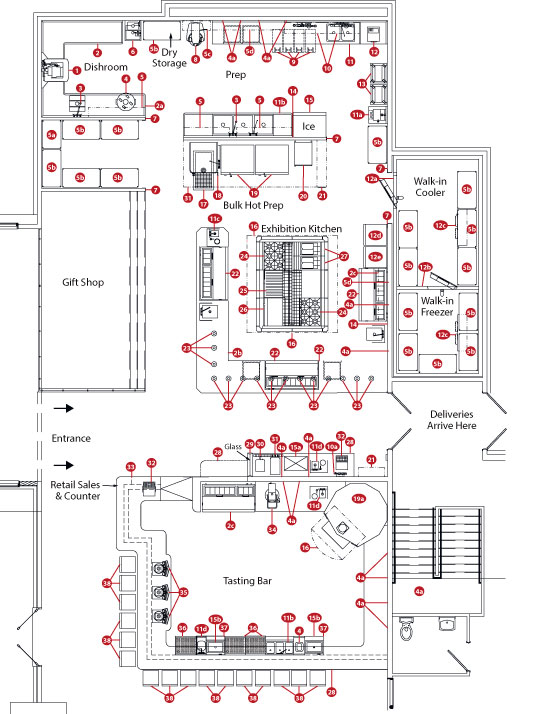

Equipment Key

1. Ice bin

2. Ice machine

3. Storage shelving

3a. Walk-in shelving

3b. Wall shelving

3c. 7-ft. sorting shelving

3d. Chemical storage shelving

4. Pallet storage

5. Walk-in freezer w/floor

5a. Evaporator

5b. Walk-in refrigerator w/o floor

5c. One-door refrigerator

5d. Two-door freezer

5e. Walk-in & freezer combo w/freezer floor

5f. Worktop refrigerator

6. Four 4-ft. worktables

6a. Prep station table

6b. 8-ft. worktable w/sink

6c. Custom clean table

6d. 4-ft. worktable

6e. 3-ft. worktable

6f. S/s table

6g. Prep table

6h. 8-ft. prep table w/double well w/ sink

6i. 5-ft. worktable w/sink

6j. 5-ft. worktable

6k. 6-ft. worktable w/sink

6l. Prep sandwich table

6m. Pizza prep sandwich table

6n. 7-ft. left dish-landing soil table w/sink

7. Slicer

8. C02

9. Fountain syrup

10. Hand sink

10a. Three-compartment sink

10b. Mop sink

11. Grease trap

12. Dishmachine

12a. Booster for dishmachine

13. Fly fan

14. Dishwasher hood

14a. Back BBQ & banquet hood

14b. Main fryer hood

15. Ansul fire suppression system

16. Wall lining

17. Soda towers

18. Cash registers

18a. POS systems

19. Water filtration system

20. Bun rack

21. Warming drawers

22. Food warmer

22a. Fryer warmers

22b. Fryer/chicken strip warmer

22c. Nacho cheese warmer

22d. Pizza warmer

23. Bun toaster

24. Meat smoker

24a. Meat smoker holder

25. Double-stack convection ovens

25a.Pizza oven

26. 10-burner range

27. Fryers

28. Pretzel holder

28a. Pretzel cookers

29. Blenders

30. Pasta sauce warmers

31. Pasta cooker