A Q&A with Greg Ginther, Business Development Sales Manager, ICS

What are some of the challenges facing QSRs today?

QSR before. ICS cold storage units can free up valuable kitchen space.Greg Ginther: Probably the number-one challenge is labor — just getting staff to work in the restaurant. There are plenty of restaurants that are open, but some have closed because they couldn’t get help. And supply chain bottlenecks — there are products that were at one time abundantly available and they’re not as available anymore. There is also a nationwide shortage of truck drivers. So, what’s happened to QSRs and many other businesses is that deliveries they were getting three and four times a week have been reduced to two or three times, just because of a shortage of drivers. As a result, they still have to get the same amount of product in, but they have to get it in fewer deliveries. So now we’ve got a storage problem: “Where are we going to put this stuff?”

QSR before. ICS cold storage units can free up valuable kitchen space.Greg Ginther: Probably the number-one challenge is labor — just getting staff to work in the restaurant. There are plenty of restaurants that are open, but some have closed because they couldn’t get help. And supply chain bottlenecks — there are products that were at one time abundantly available and they’re not as available anymore. There is also a nationwide shortage of truck drivers. So, what’s happened to QSRs and many other businesses is that deliveries they were getting three and four times a week have been reduced to two or three times, just because of a shortage of drivers. As a result, they still have to get the same amount of product in, but they have to get it in fewer deliveries. So now we’ve got a storage problem: “Where are we going to put this stuff?”

Has storage historically been an issue with QSRs, or is this fairly recent?

GG: I think it’s become more of a problem in recent years. Menus have expanded and diversified. If you think back to early QSRs, they had a very limited menu. Over time, to remain competitive, they’ve had to expand and offer products they didn’t dream they would ever have to offer. They’ve had to expand their menus and diversify, which has in recent years led to issues with storage, both in cold and dry storage.

So how can ICS help QSRs that are dealing with the storage problem?

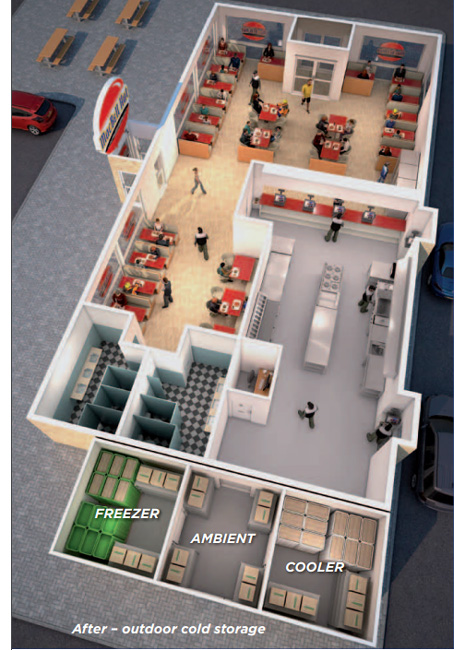

QSR afterGG: We can expand their cold storage space and their stockroom or ambient dry storage space very easily by adding our walk-ins to the exterior of the existing restaurant. It’s a really simple operation to bring one of our one-piece buildings that are prefabricated in the factory and attach it to the back of the building. Suddenly, you have additional storage space without impacting the interior footprint of the restaurant. For example, a large walk-in freezer inside your restaurant can be eliminated, and that would create additional kitchen space or potentially even create additional space for the dining room — just by moving that cooler or freezer to the exterior of the building.

QSR afterGG: We can expand their cold storage space and their stockroom or ambient dry storage space very easily by adding our walk-ins to the exterior of the existing restaurant. It’s a really simple operation to bring one of our one-piece buildings that are prefabricated in the factory and attach it to the back of the building. Suddenly, you have additional storage space without impacting the interior footprint of the restaurant. For example, a large walk-in freezer inside your restaurant can be eliminated, and that would create additional kitchen space or potentially even create additional space for the dining room — just by moving that cooler or freezer to the exterior of the building.

How does the ICS product line differ from traditional walk-in coolers?

GG: What really differentiates us from others is that we can fabricate a walk-in or drive-thru window that is simply bolted onto the exterior of your restaurant. If you don’t currently have a drive-thru, ICS can manufacture one for you and you can be in the drive-thru business in a day. When we manufacture our walk-ins, the refrigeration is attached to the walk-in in the plant and is run-tested. So when it leaves our manufacturing facilities, it’s fully assembled and ready to be dropped off on your site. Most companies offer a panelized unit which is essentially shipped in pieces on pallets. It has to be assembled on site, which is time-consuming and costly. With our one-piece walk-ins, when we get to your site, you can be in business in three hours.