The new kitchen at the University of Kentucky HealthCare's Albert B. Chandler Hospital supports patient meals, retail venues and dining rooms.

Upon walking into Pavilion A of the Albert B. Chandler Hospital at the University of Kentucky (UK), one enters the quintessential modern healthcare facility. A comforting, welcoming and healing environment greets patients, visitors and staff as they step into a spacious, light-filled atrium lobby. A stainless steel and mesh fabric sculpture hangs suspended beneath a three-story skylight. Throughout the hospital, elements of nature and art that are representative of the state and its people contribute to the healing process.

Upon walking into Pavilion A of the Albert B. Chandler Hospital at the University of Kentucky (UK), one enters the quintessential modern healthcare facility. A comforting, welcoming and healing environment greets patients, visitors and staff as they step into a spacious, light-filled atrium lobby. A stainless steel and mesh fabric sculpture hangs suspended beneath a three-story skylight. Throughout the hospital, elements of nature and art that are representative of the state and its people contribute to the healing process.

As part of the new hospital project, UK HealthCare Food and Nutrition Services, which is managed by Morrison Healthcare/Compass USA, expanded to serve patients, visitors and staff. A kitchen on the lower level supports a combination pod- and catering associates–style model capable of serving up to 700 patients daily. Room service is expected to go live in the fall of 2017 for new mothers, pediatric patients and oncology patients. The kitchen also supports Chandler Dining, a retail cafe on the first floor, as well as three other retail operations in Pavilion A. Catering services are also offered.

The Initial Plan

Signage featuring fresh berries and locally sourced beef welcomes customers to Chandler Dining.A master plan was completed by Rippe Associates' Robert Rippe, president, and Christine Guyott, FCSI, RD, principal, along with the architectural firm Ellerbe Becket. The UK HealthCare Project kicked off in 2007 with building the Albert B. Chandler Hospital to modernize the hospital due to the rapidly changing nature of healthcare delivery.

Signage featuring fresh berries and locally sourced beef welcomes customers to Chandler Dining.A master plan was completed by Rippe Associates' Robert Rippe, president, and Christine Guyott, FCSI, RD, principal, along with the architectural firm Ellerbe Becket. The UK HealthCare Project kicked off in 2007 with building the Albert B. Chandler Hospital to modernize the hospital due to the rapidly changing nature of healthcare delivery.

"At that time, the academic medical center was in flux about how many beds it would increase," Guyott says. "Though several scenarios were presented, the one clear direction was that most of the patients were going to be in the new tower in Pavilion A, which was on the opposite side of campus from the current foodservice department and existing patient beds in Pavilion H."

The plan was to design the foodservice in the new Chandler tower in Pavilion A but not to build it out until there were more patients in the building and the floors were built out. "The initial planning included designing the main kitchen and retail cafe for the new tower up to the design development phase and putting it on hold," Guyott says. At the same time, Courtyard Café, a coffee shop/bistro, was planned in the new building to offer some food for the staff and visitors who moved over to the new side of campus. The team knew Courtyard Café would have a lot of volume from when it opened in 2011 until the new main retail space, Chandler Dining, opened in 2016.

The UK facilities team kept in touch with Rippe Associates from 2007 until 2014, when the time came to complete the documents and begin the construction for Chandler Dining. "We finished the designs with Stengel Hill Architecture and the current Morrison's team," Guyott says.

At Southside Grill, staff use a flattop griddle to cook traditional grill fare such as hamburgers, grilled cheese sandwiches, portobello mushroom burgers, fish burgers and veggie burgers. Fryers heat french fries and chicken tenders. Customers may help themselves to myriad sandwich toppings."The project was not phased due to this being a build-out of planned shell space," Guyott says. "Construction started in June of 2015 and was opened in August of 2016. Strategically the kitchen opened a week early to serve patients only prior to opening to the public."

At Southside Grill, staff use a flattop griddle to cook traditional grill fare such as hamburgers, grilled cheese sandwiches, portobello mushroom burgers, fish burgers and veggie burgers. Fryers heat french fries and chicken tenders. Customers may help themselves to myriad sandwich toppings."The project was not phased due to this being a build-out of planned shell space," Guyott says. "Construction started in June of 2015 and was opened in August of 2016. Strategically the kitchen opened a week early to serve patients only prior to opening to the public."

Due to the amount of space required for the food and nutrition services, putting the kitchen, servery and dining on one level was not feasible. Instead, the design team split the department on two levels — the kitchen in the basement and the servery and dining on the first level — and placed a dedicated elevator to facilitate transport between the two spaces. "This allowed supplies and patient tray carts to stay in the service corridors and put the retail with excellent access to the pedestrian walkway on the first floor," says Mark L. Spies, AIA, LEED AP, principal, Stengel Hill Architecture. "A new sweeping elevated walkway connects the parking garage to the main Chandler building, and most of the people walk past this new retail area."

Overcoming Challenges

Staff make large quantities of mashed potatoes in tilting kettles.The logistical aspect of this project created enormous challenges. "The location of the kitchen in the basement provided logistical construction challenges, such as concrete slab pours and routing exhaust ductwork up through the bed tower," Spies says.

Staff make large quantities of mashed potatoes in tilting kettles.The logistical aspect of this project created enormous challenges. "The location of the kitchen in the basement provided logistical construction challenges, such as concrete slab pours and routing exhaust ductwork up through the bed tower," Spies says.

The floor wasn't poured during the subsequent pause time, so that wasn't the biggest obstacle. "The biggest was the exhaust ducts going up nine stories in one shaft," Guyott says. "Working on access and how to get them all in was a challenge. A lesson we learned is, be sure there are cleanouts and that there is room for the ducts you intend to group together. The other challenge is that even though the design was complete, a new management team always has its own ideas on equipment and layout. While this didn't change significantly, there were limitations with what we could change for the final documents."

In addition, the build-out of a new radiology department on the ground floor was ongoing during this project, Spies says. "The kitchen was immediately below and the cafeteria/servery was immediately above this radiology project. Close coordination with mechanical, electrical and plumbing infrastructure was needed. Also, proper installation of lead shielding for the MRIs had to be closely coordinated with kitchen infrastructure."

The kitchen features both a pod and room service system for patient trays.Despite the challenges, Chandler Dining "became an established dining facility that is not just a hospital cafeteria but rather a dining destination not only for patients, visitors and staff but also for the community," Guyott says.

The kitchen features both a pod and room service system for patient trays.Despite the challenges, Chandler Dining "became an established dining facility that is not just a hospital cafeteria but rather a dining destination not only for patients, visitors and staff but also for the community," Guyott says.

Also on the first floor, the dining room provides 292 seats. Two private dining areas provide 40 seats combined and an outdoor terrace contains 90 seats.

Chandler Dining's servery and dining areas feature an open, airy ambiance bringing in natural light. Lighting and architecture highlight different service lines. Contemporary yet durable finishes contribute to the upscale environment, though they must be easy to maintain since the operation is open 24 hours on weekends and holidays.

Through the UK Arts and Healthcare program, the facility displays commissioned artists' work. Recently a 29-foot oil painting on linen by Joyce Garner was hung to run the expanse of the banquet seating area. Another exhibit features a touch of nature with a collection of jars containing dirt from all 120 counties in Kentucky.

Kitchen Storage, Preparation and Room Service

A catering associate takes carts to the floors and picks up trays when patients are finished, places them on carts and delivers them to the warewash area in the kitchen.After food deliveries arrive at the loading dock on the ground floor, staff transport them to storage areas in the lower level. "Because the kitchen is located on the lower level and there was not going to be a new dock that served this side of campus, the flow from the dock to the foodservice is a long way away," Guyott says. "But the supply/freight elevator is directly behind the foodservice department, and items have a straight flow from the elevator into the storage rooms."

A catering associate takes carts to the floors and picks up trays when patients are finished, places them on carts and delivers them to the warewash area in the kitchen.After food deliveries arrive at the loading dock on the ground floor, staff transport them to storage areas in the lower level. "Because the kitchen is located on the lower level and there was not going to be a new dock that served this side of campus, the flow from the dock to the foodservice is a long way away," Guyott says. "But the supply/freight elevator is directly behind the foodservice department, and items have a straight flow from the elevator into the storage rooms."

Cold storage on the basement level includes seven walk-in coolers in a main corridor as well as areas for baking, catering and salad prep. Food is also stored in two walk-in freezers and dry storage.

The storage was set up so that it could be run as a secure storeroom issuing out product or open to the staff. The paper and beverage storage are located near the dedicated elevator that goes up to the retail on the first floor for efficiency in resupply of these popular items. Several working refrigerators and freezers sit close to the production areas. "Because the patient service carts were exiting one side of the space, and the retail items the other, the cold food production and the hot food production were located between the two," Guyott says.

Core production takes place in cooks' prep areas containing five kettles, a mixer, slicers, blenders, worktables, two meat slicers, a floor mixer that complements another floor mixer closer to the bakery, two countertop food processors and a blast chiller. Hot food prep equipment includes a range, a flattop grill, four combi ovens, a roll-in combi oven, a chargrill and a 75-pound fryer.

Each day, staff transport menu ingredients upstairs to the refrigerators at the food concept stations. "Staff assemble and prepare food at most stations," says Terri Schnurr, CDM, CFPP, enterprise director of Food and Nutrition Services, Morrison Healthcare/Compass USA. "Some hot items that are cooked in the kitchen are brought upstairs to be served in Traditions station."

Above: Due to the multilevel department, the design includes two dish rooms to enhance efficiency. One dish room sits on the basement level for patient service and washes the kitchen pots and pans. The other dish room sits upstairs in support of the retail operation.The kitchen features both a pod and room service system for patient trays. Morrison's patient meal program, My Dining, includes the pod-style system featuring catering associates who visit patients' rooms and take orders for the next meal. The catering associate transmits orders via a tablet computer to the kitchen where culinary staff work among the five pods to assemble the food. "At the pods, we have three bays with two catering associates at each bay to place food onto the trays and the trays onto carts," Schnurr says. A catering associate takes carts to the floors and picks up trays when patients are finished. The associate then places the trays on carts and delivers them to the warewash area in the kitchen.

Above: Due to the multilevel department, the design includes two dish rooms to enhance efficiency. One dish room sits on the basement level for patient service and washes the kitchen pots and pans. The other dish room sits upstairs in support of the retail operation.The kitchen features both a pod and room service system for patient trays. Morrison's patient meal program, My Dining, includes the pod-style system featuring catering associates who visit patients' rooms and take orders for the next meal. The catering associate transmits orders via a tablet computer to the kitchen where culinary staff work among the five pods to assemble the food. "At the pods, we have three bays with two catering associates at each bay to place food onto the trays and the trays onto carts," Schnurr says. A catering associate takes carts to the floors and picks up trays when patients are finished. The associate then places the trays on carts and delivers them to the warewash area in the kitchen.

When room service begins in the fall of 2017, one of the five pods will be converted back to its originally designed function as a room service station to serve meals on demand to new mothers, pediatric patients and oncology patients.

Due to the multilevel department, the design includes two dish rooms to enhance efficiency. One dish room sits on the basement level for patient service and washes the kitchen pots and pans. The other dish room sits upstairs in support of the retail operation.

Chandler Dining

Italian Trattoria features a stone-hearth pizza oven that bakes pizza, cook-to-order pasta, stromboli and flatbread.Staff place food for Chandler Dining on carts and transport it upstairs via a dedicated elevator. Staff deliver food to the various concept stations where it is stored in refrigerators. Hot food gets transferred directly into steamtables.

Italian Trattoria features a stone-hearth pizza oven that bakes pizza, cook-to-order pasta, stromboli and flatbread.Staff place food for Chandler Dining on carts and transport it upstairs via a dedicated elevator. Staff deliver food to the various concept stations where it is stored in refrigerators. Hot food gets transferred directly into steamtables.

The servery features 9 stations and 8 checkout lines. Many stations in this 8,500-square-foot space feature a la minute cooking, which appeals to this diverse customer base that includes outpatients, staff, visitors and medical school students. "In the old cafeteria, there was no space to prepare food in front of customers except at a grill," Schnurr says. "Now every area has its own equipment for food preparation and service."

Italian Trattoria features a stone hearth pizza oven that bakes pizza, cook-to-order pasta, stromboli and flatbread. Salads and specialty desserts are also available here. A nearby beverage area offers tea, coffee, soft drinks and water. A water-container filling station allows customers to bring their own vessels and take water with them.

Traditions contains a traditional steamtable offering two entrees, vegetables, side dishes, hot desserts, rolls and cornbread. "We offer a 21-day rotation menu here, offering everything from grilled salmon, cod, chicken and lasagna," Schnurr says. The station also features breakfast items including eggs, bacon, biscuits and gravy.

Chef Table features rotating entrees and sides. This area also doubles as a demonstration kitchen with digital screens and monitors that show chefs in action from 4 p.m. until 5 p.m. once a month.At Southside Grill, staff use a flattop griddle to cook traditional grill fare such as hamburgers, grilled cheese sandwiches, portobello mushroom burgers, fish burgers and veggie burgers. Fryers heat french fries and chicken tenders. Customers may help themselves to myriad sandwich toppings. "Fridays are grass-fed Fridays," Schnurr says. "We partner with local farmers and serve grass-fed beef and free-range chicken."

Chef Table features rotating entrees and sides. This area also doubles as a demonstration kitchen with digital screens and monitors that show chefs in action from 4 p.m. until 5 p.m. once a month.At Southside Grill, staff use a flattop griddle to cook traditional grill fare such as hamburgers, grilled cheese sandwiches, portobello mushroom burgers, fish burgers and veggie burgers. Fryers heat french fries and chicken tenders. Customers may help themselves to myriad sandwich toppings. "Fridays are grass-fed Fridays," Schnurr says. "We partner with local farmers and serve grass-fed beef and free-range chicken."

Exhibition cooking attracts customers to Chef Table. Staff prepare a one-week rotating menu of Mediterranean, Asian, Americana, Latin and chophouse cuisines. "What's nice is we use interchangeable equipment," Schnurr says. "For instance, cooks use woks for Asian and a chargrill, flattop and saute range for other ethnic cuisines." At breakfast, culinary staff prepare made-to-order omelets, waffles, pancakes and burritos.

This area also doubles as a demonstration kitchen with digital screens and monitors that show chefs in action from 4 p.m. until 5 p.m. once a month. "The chefs emphasize healthy meal preparation and feature sustainable menu items," Schnurr says. "They collaborate with dietitians and medical staff as well. For example, a neurologist will speak about cooking to alleviate migraines. We want to lead more initiatives like this. Last week my sous chef attended a culinary medical seminar and heard chefs, dietitians and medical professionals speak about collaborating."

Wild Greens presents fresh ingredients for customers to make their own salads. A sushi station sits adjacent to the salad station.A rectangular-shaped space contains Chop Chop, Wild Greens, Sushi, Soup and On the Go. Chop Chop station features made-to-order salads, flatbreads and load-your-own baked potatoes. Wild Greens, the salad bar, features fruit and yogurt with many toppings at breakfast in addition to fresh breads. The bar converts to an expansive salad bar at lunch and dinner. Fresh ingredients include seasonal produce displayed raw and in compound salads. Two types of grain and pasta salads are offered daily.

Wild Greens presents fresh ingredients for customers to make their own salads. A sushi station sits adjacent to the salad station.A rectangular-shaped space contains Chop Chop, Wild Greens, Sushi, Soup and On the Go. Chop Chop station features made-to-order salads, flatbreads and load-your-own baked potatoes. Wild Greens, the salad bar, features fruit and yogurt with many toppings at breakfast in addition to fresh breads. The bar converts to an expansive salad bar at lunch and dinner. Fresh ingredients include seasonal produce displayed raw and in compound salads. Two types of grain and pasta salads are offered daily.

At Sushi Bar, chefs working for a local franchise prepare sushi to order as customers watch them assemble ingredients. A nearby soup bar features four soups daily. On the Go, which is the first station customers see as they enter Chandler Dining, features large open-air coolers containing beverages, salads, sandwiches, yogurt and other prepackaged, house-made to-go foods. In addition, an area featuring house-made packaged foods sits adjacent to On the Go.

Chandler Dining also contains Deli, featuring fresh carved meats and made-to-order salads and sandwiches. The tea and coffee area offers branded drinks, house-made baked goods and specialty desserts.

Sustainability, Energy-Saving Features and Efficiencies

The Deli features freshly carved meat, wraps and made-to-order sandwiches.Here's how some of the environmentally friendly features at Albert B. Chandler Hospital support green efforts:

The Deli features freshly carved meat, wraps and made-to-order sandwiches.Here's how some of the environmentally friendly features at Albert B. Chandler Hospital support green efforts:

- LED lighting provides the latest in lighting technology, which will save up to 30 percent compared to traditional lighting.

- A smart lighting control system schedules when lights turn off. In individual rooms, such as offices and staff restrooms, vacancy sensors automatically shut off the lights if rooms are unoccupied. Manual operation of the local light control switch turns the lights on.

- Adjustable dimmer switches on lighting allow flexibility in lighting output, resulting in greater occupant control as well as reduced energy use.

- When outdoor air temperatures permit, the air handlers will switch to an "economizer mode" using cooler outside air to condition the kitchen space in lieu of using hospital-chilled water to cool the air.

- In the rare occasion when a station closes, the hoods' air handlers switch into an energy-saving setback mode that reduces the airflow to the space during periods of lower use to maximize energy savings.

- UV lighting technology helps purify the air; these lights also serve to prevent dirt and grime from coating the cooling coil, resulting in substantial energy savings over time.

Due to the distance of the kitchen from the dock, the foodservice consultants wanted to find a way to reduce the number of trips staff must make from the kitchen to the dock to deliver waste. Consultants designed the kitchen's soiled dish area with a slow speed grinder that can take most any foodservice refuse item and grind it up, remove the water and leave the solid waste at 80 percent of its original volume.

"Also, because the retail operation was going to use disposables, we did not have a large enough grinder in which to put whole trash bags with nonfood items, but we are still looking for solutions to grind and dispose of whole bags of trash to reduce the amount of waste on this level as well," Guyott says.

As more customers discover Chandler Dining, they are going out of their way to come taste the fare and enjoy the open environment. Each day is a journey for the staff to learn to interact with customers and continue to bring more synergy between healthful cooking and positive dining experiences.

Facts of Note

- About the Hospital: The new 512-bed UK Albert B. Chandler Hospital Pavilion A is part of the UK HealthCare patient care enterprise. The hospital also contains Pavilions H and HA.

- Project Opened: The hospital's kitchen and Chandler Dining opened in August 2016. The earliest part of the project, the Courtyard Café, opened in 2011.

- Scope of Project: This project encompassed the build-out of existing shell space on the basement and first floor of Pavilion A in the Albert B. Chandler Hospital to create a new kitchen in the basement and Chandler Dining, a retail serving area and dining room, on the first floor. The kitchen produces food for four retail foodservice outlets at the hospital: Chandler Dining in Pavilion A, Courtyard Café in Pavilion A, Whitney-Hendrickson Café in the Markey Cancer Center and Wildcat Café in the Kentucky Clinic. The kitchen also produces food for a pod-style patient service program with catering associates serving the majority of patients with scheduled delivery meals. Patient rooms are housed in: Pavilion A on floors 6 through 10 and soon on floor 11 for oncology patients; in Pavilion H on floors 3 through 8; in Markey Cancer Center on 2 floors; at Children's Hospital (attached to Pavilion H) on a single floor; and Gill Heart and Vascular Institute. Room service for new mothers, pediatric patients and oncology patients is expected to go live by the fall of 2017. Food and Nutrition Services also provides catering services all over the campus.

- Size: Chandler Dining Kitchen, Café and Dining Room encompass approximately 35,350 sq. ft., including 17,000 sq. ft. for the kitchen, 8,500 sq. ft. for the servery and 5,200 sq. ft. for dining room seating

- Seats: 292 in the main dining room, 48 in 2 private dining rooms, and up to 90 on an outdoor terrace

- Average Check: $5.24

- Total Annual Sales: $7.2 million

- Daily Transactions: 3,764 for Chandler Dining; 1,625 patient meals

- Hours: Monday through Friday: breakfast, 6 a.m. to 10 a.m.; closed 10 a.m. to 11 a.m.; lunch, 11 a.m. to 2 p.m.; light lunch, 2 p.m. to 4 p.m.; dinner, 4 p.m. to 7 p.m.; late night, 7 p.m. to 5 a.m.; closed 5 a.m. to 6 a.m., Monday through Friday. Weekends and holidays: open 24 hours.

- Menu Specialties: 9 stations, including Italian Trattoria (pizza, made-to-order pasta stromboli and daily salads); Deli (freshly carved meats); Chef Table (exhibition station); Traditions (traditional, home-style meals); Chop Chop (made-to-order signature salads, flatbreads and potato bar); Salad/Soup Bar; Southside Grill (hamburgers, grilled cheese, french fries, chicken and fish); Sushi; and Wild Greens. On the Go offers takeout fare.

- Staff: 214 full-time employees, including 13 managers

- Total Cost: N/A

- Equipment Investment: $3.5 million for Chandler Dining and Kitchen; $460,000 for Courtyard Café

- Website: www.ukhealthcare.uky.edu

Key Players

- Owner: UK HealthCare

- Executive Vice President for Health Affairs: Dr. Michael Karpf

- Vice President and Chief Clinical Operations Officer, UK HealthCare: Robert Cofield

- Senior Advisor for Health Affairs, UK HealthCare: Murray Clark

- Director of Enterprise Operations, UK HealthCare: J.J. Housley, PharmD, MBA

- Director of Facilities Planning & Development UK HealthCare: Jennifer Christmann, FACHE

- Enterprise Director of Food and Nutrition Services, Morrison Healthcare/Compass USA: Terri Schnurr, CDM, CFPP

- Associate Director, Food and Nutrition Services, Morrison Healthcare/Compass USA: Christina Swann

- Enterprise Executive Chef, Food and Nutrition Services, Morrison Healthcare/Compass USA: Pete Combs, CDM, CFPP

- Sous Chefs at Chandler Hospital, Healthcare/Compass USA: Justin Clark and Sarah Null

- Retail Manager, Chandler Dining and Other Retail Units, Morrison Healthcare/Compass USA: Steven Maxwell

- Patient Service Manager, Morrison Healthcare/Compass USA: Chad Knight

- Human Resources Specialist, Morrison Healthcare/Compass USA: Cecilia Riddle

- Architect: Stengel Hill Architecture, Louisville, Ky.; Mark L. Spies, AIA, LEED AP, principal

- Interior Design: HDR, Chicago; Megan Kalina, EDAC, CID, LEED AP; and Stengel Hill Architecture; Kelly Spies, associate IIDA, interior designer

- Mechanical/Electrical Design: CMTA Inc.; Kevin D. Mussler, PE, CxA, LEED AP, vice president

- Foodservice Consultants: Rippe Associates, Minneapolis; Robert Rippe, president; Christine Guyott, FCSI, RD, principal; Jessica Dengel, senior project manager; and Joy Enge, RD, senior equipment specialist

- Equipment Dealer: Great Lakes Equipment, Brighton, Mich., office

- Construction: Turner Construction Company, Lexington, Ky.; David R. Opalka, area manager

Meet the Players

Pete Combs, CDM, CFPP, Enterprise Executive Chef, Food and Nutrition Services, Morrison Healthcare/Compass Group USA. Before joining Morrison Healthcare, Combs worked at the Trellis Restaurant in Williamsburg, Va., and Green Hills Grille in Nashville, Tenn. Pete is a three-time winner of the Signature Chef Award and the 2016 Compass Deliver Flavor Award. He was part of the chef team for the 2002 Olympics in Salt Lake City.

Jessica Dengel, senior project manager, Rippe Associates. Since Dengel began working in foodservice facilities planning in 2004, her experience has included work in healthcare, schools and business and industry. She handles CAD work and ongoing coordination with architects, engineers and code officials throughout construction and final inspection.

Joy Enge, RD, senior equipment specialist, Rippe Associates. With work experience in hospital and long-term care foodservice operations, Enge is responsible for cost estimates, equipment selection and research, specification writing and developing foodservice systems and plans.

Christine Guyott, FCSI, RD, Rippe Associates. Prior to joining Rippe Associates, Guyott, a veteran of the foodservice industry with more than 30 years of experience, was a healthcare specialist working primarily with long-term care facilities and hospitals. With her background in healthcare, she has an ability to conceptualize and give attention to detail to provide schematic and functionally oriented designs to match project goals at academic medical centers, critical access hospitals and other hospital facilities.

Terri Schnurr, CDM, CFPP, Enterprise Director of Food and Nutrition Services, Morrison Healthcare/Compass Group USA. Schnurr oversees a three-hospital system at UK HealthCare. Prior to working in an acute care setting, she held positions in fine dining establishments. She joined Morrison Healthcare in 2000 and began her healthcare career at Norton Hospital in Louisville. Schnurr combines her love of food and interest in nutrition with a passion for wellness and fitness. She and her team at UK HealthCare were awarded the Compass Deliver Flavor Award in 2015 and Retail Excellence Award in 2016.

Mark L. Spies, AIA, LEED AP, principal, Stengel Hill Architecture. Spies joined Stengel Hill Architecture in 2000. He is heavily involved in all aspects of the firm from planning and design to business development. Other projects include radiology department build-out at the University of Kentucky and a patient care expansion project at The George Washington University Hospital.

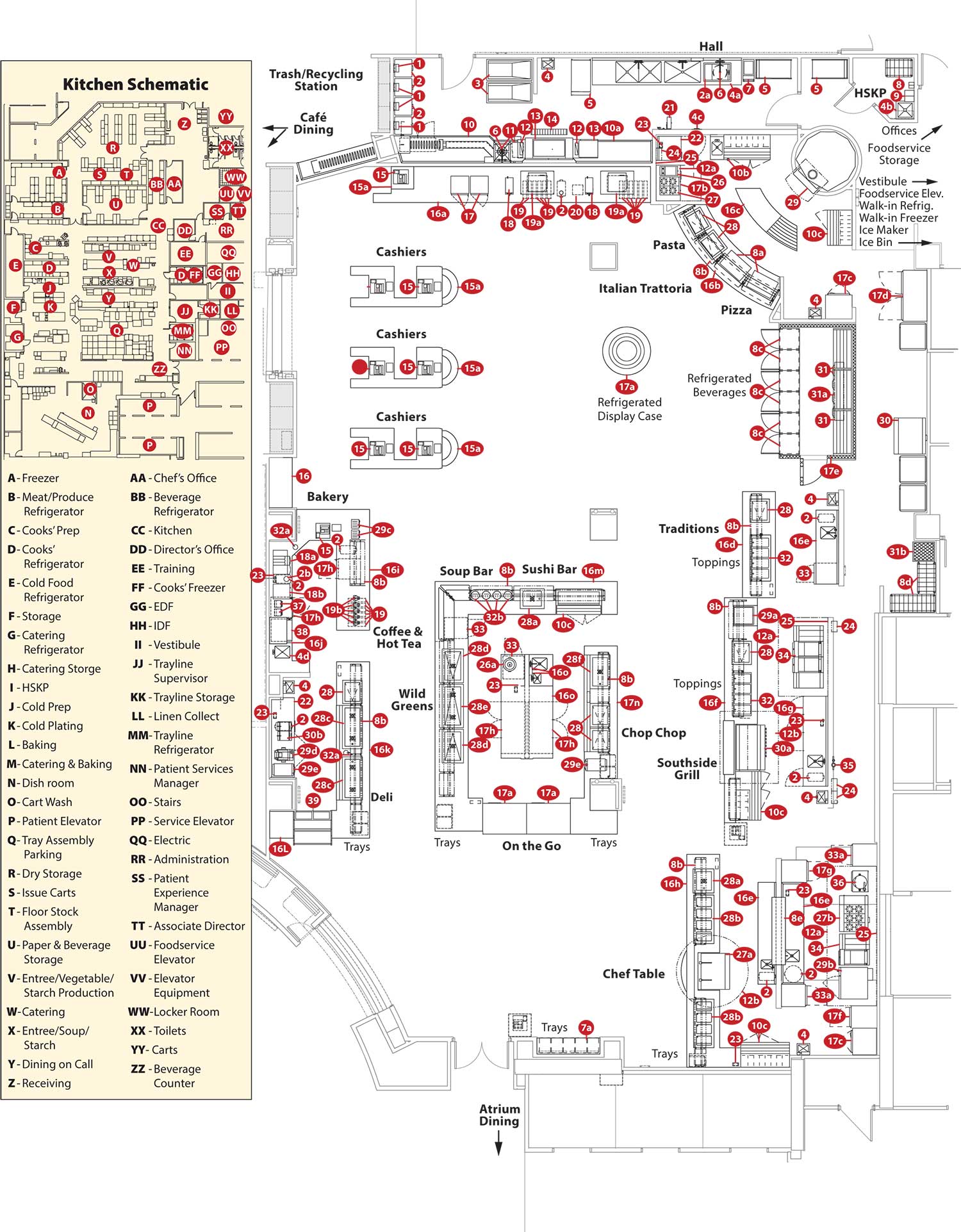

Equipment Key

1. Flatware chute

2. Trash bin

2a. Waste collector

2b. Knock box

3. Tilt truck

4. Hand sink

4a. Pot & pan sink w/agitator

4b. Mop sink

4c. Eye/face wash station

4d. Undermount sink

5. Pan cart

6. Spray rinse

7. Tray dispenser

7a. Tray stand

8. Detergent shelving

8a. Heated display shelf

8b. Protector shelf system

8c. Bottled beverage shelving

8d. Dry storage

8e. Overshelf

9. Detergent dispensing system

10. Soiled dishtable w/tray return conveyor

10a. Clean dishtable

10b. Refrigerated prep table w/sink

10c. Refrigerated prep table

11. Mini pulper

12. Exhaust duct riser

12a. Exhaust hood

12b. Island exhaust hood

13. Dishmachine w/booster heater & dryer

14. Trench drain

15. Cash register

16. Coffee condiment counter

16a. Beverage/cashier counter

16b. Pizza/pasta serving counter

16c. Island work counter

16d. Comfort serving counter

16e. Work counter w/sink

16f. Grill serving counter

16g. Counter w/freezer base & sink

16h. Chef's serving counter

16i. Coffee counter

16j. Work counter

16k. Deli/salad serving counter

16l. Display counter

16m. Soups/salad counter

16n. Specials serving counter

16o. Island counter w/sinks

17. Countertop display freezer

17a. Refrigerated display case

17b. Refrigerated base

17c. Roll-in refrigerator, 1-sec.

17d. Roll-in refrigerator, 2-sec.

17e. Walk-in refrigerator w/display doors

17f. Reach-in freezer, 1-sec.

17g. Reach-in refrigerator, 1-sec.

17h. Undercounter refrigerator, 1-sec.

18. Iced tea brewer

18a. Espresso machine

18b. Coffee brewer

19. Cup dispenser

19a. Ice dispenser w/soda heads

19b. Airpot dispenser

20. Soda system

21. Hose reel

22. Refrigerated work counter

23. Printer

24. Fire protection system

25. S/s wall panel

26. Countertop pasta cooker

26a. Rice cooker

27. Countertop range

27a. Wok range

27b. Saute range w/spreader

28. Hot/cold pan, 2-well

28a. Drop-in cold pan, 2-well

28b. Hot/cold pan, 4-well

28c. Drop-in cold pan, 4-well

28d. Drop-in cold pan, 3-well, sloped

28e. Drop-in cold pan, 4-well, sloped

28f. Drop-in cold pan, 3-well, sloped

29. Stone hearth pizza oven

29a. Display warmer

29b. Combi oven, 2-sec.

29c. Toaster, 4-slot

29d. Tortilla warmer

29e. Accelerated oven

30. Grill w/cabinet base

30a. Grill w/refrigerated base

30b. Sandwich grill

31. Dunnage rack

31a. Racked refrigeration system

31b. Bread rack

32. Hot food well, 4-well

32a. Dipperwell

32b. Soup well

33. Mobile warming cabinet

33a. Reach-in warming cabinet, 1-sec.

34. Fryer w/filter, 2-sec. and dump station

35. Water filtration system

36. 12-gal. kettle w/stand

37. Blender

38. Undercounter icemaker w/bin

39. Deli display case